Large cantilever structure suitable for broadening old road of cliff road section and construction method

A technology of cliffs and construction methods, applied in infrastructure engineering, roads, roads, etc., can solve the problems of weak anti-overturning safety measures, inconvenient construction of bridge decks, and high construction risks, so as to achieve strong overall anti-overturning ability and avoid unevenness Settlement, the effect of high structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

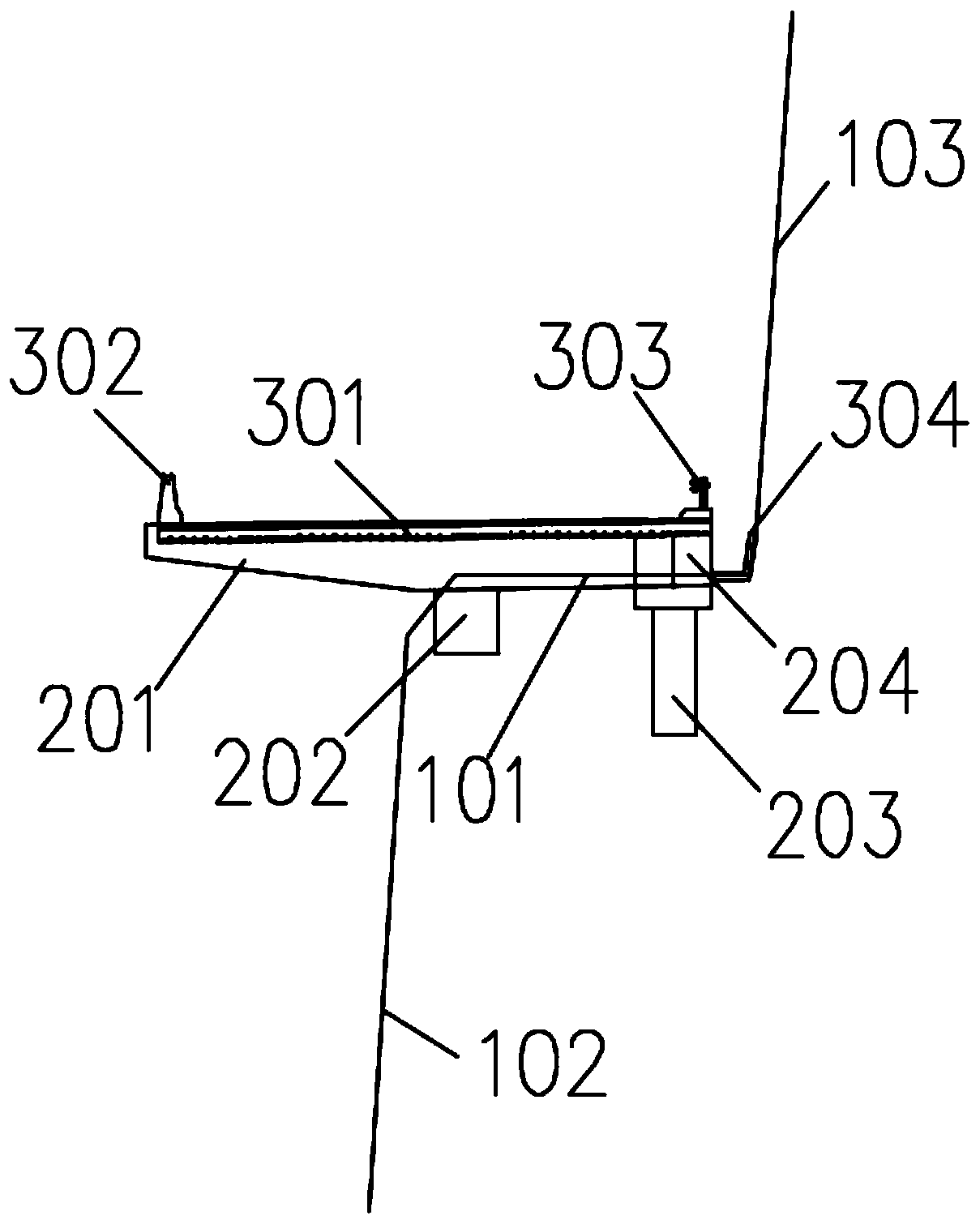

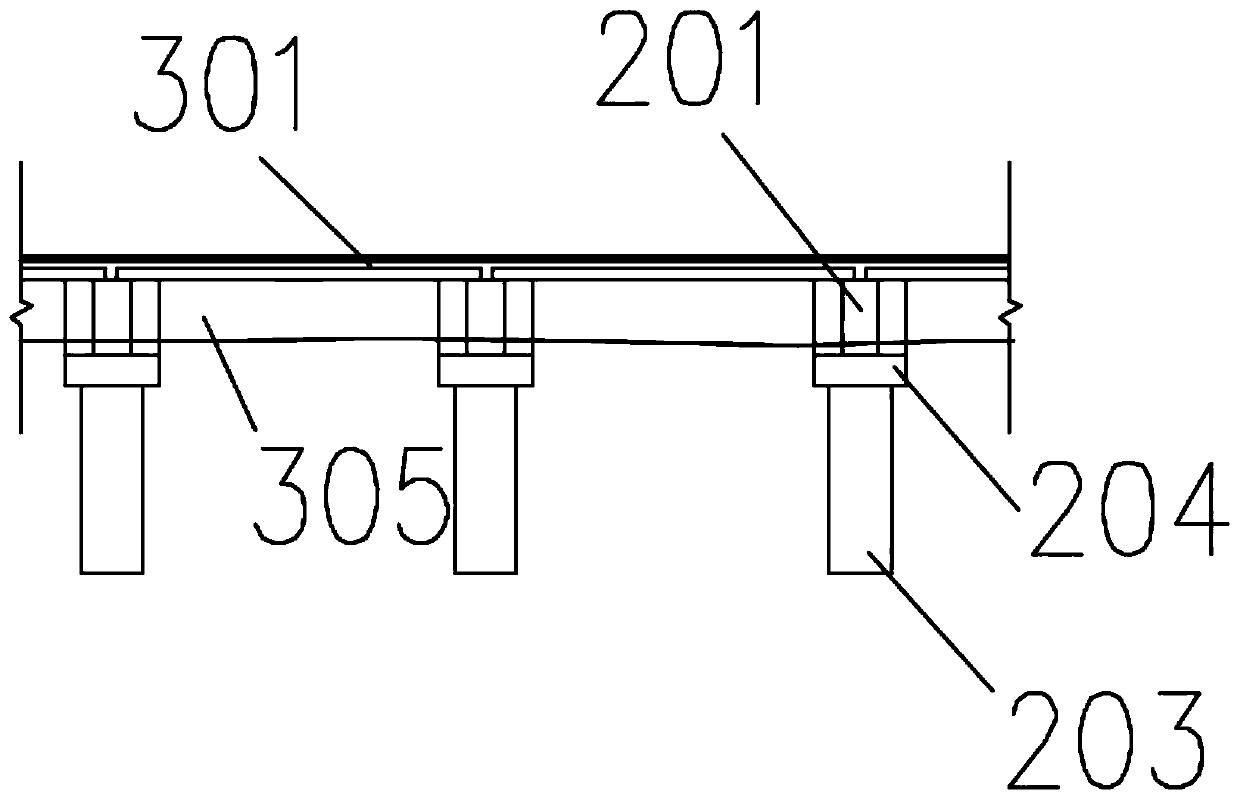

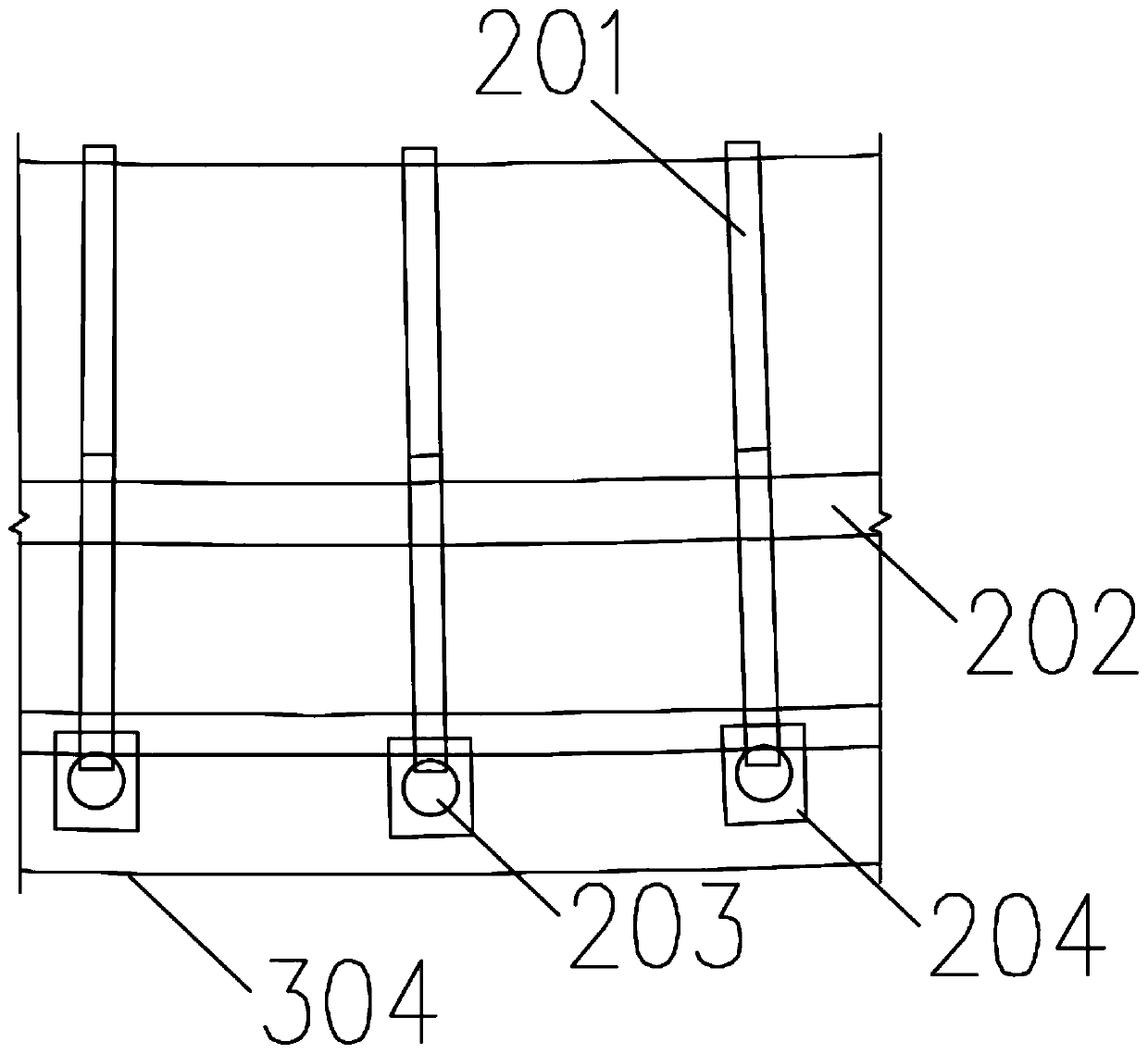

[0051] like Figure 1-5 As shown, a large cantilever structure suitable for the widening of the old road in the cliff section includes the old road 101, the lower slope cliff 102 and the upper slope cliff 103, and the lower slope cliff 102 and the upper slope cliff 103 are respectively located on both sides of the old road 101, The old road 101 is provided with a strip foundation 202, an uplift pile 203 and a pile cap 204. The strip foundation 202 is arranged near the cliff 102 of the lower slope, and the strip foundation 202 is arranged along the length direction of the old road 101. The length of the strip foundation 202 is the same as the desired The widened old road has the same length, the uplift piles 203 are arranged close to the upper slope cliff 103 , and the pile caps 204 are arranged on the uplift piles 203 .

[0052] The old road 101 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com