Immediate processing method for hydraulic fill of ultra-soft foundation by modified vacuum preloading and water-covering preloading

A treatment method and technology for soft foundations, which are used in infrastructure engineering, pontoon bridges, soil protection, etc., can solve the problems of affecting the progress of the project, rising sand prices, and high costs, improving overall stiffness and stability, and accelerating drainage and consolidation. , The effect of saving project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

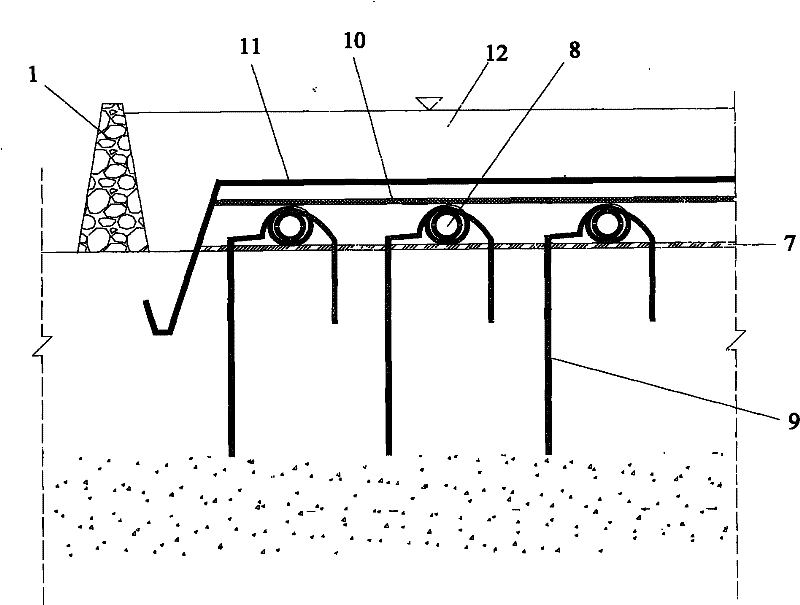

[0037] Such as figure 1 , 2 , 3 and 4 show:

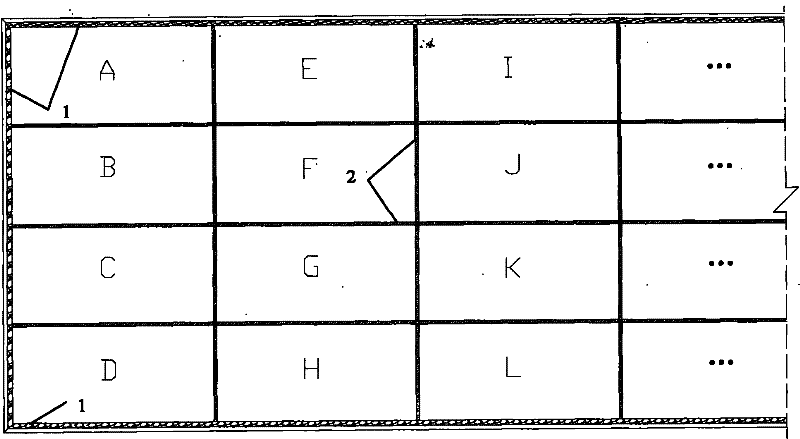

[0038] (1) According to the shape size of the foundation treatment area and the position of the embankment 1, measure the setting out, plan the position of the pontoon 2 on the mud, and each treatment area ( figure 1 In the position of A, B, C, ...), each processing area is divided into several vacuum preloading blocks;

[0039] (2) spread mud on the pontoon bridge 2 from one end of the reinforcement site, first place the rubber foam board 3 flat on the dredging mud, and connect end to end;

[0040] (3) Drill 2 circular holes with a diameter of 2 cm at both ends of each rubber foam board 3, and use ropes to pass through the round holes of two adjacent rubber foam boards 3, and connect all rubber foam boards 3 end to end in sequence;

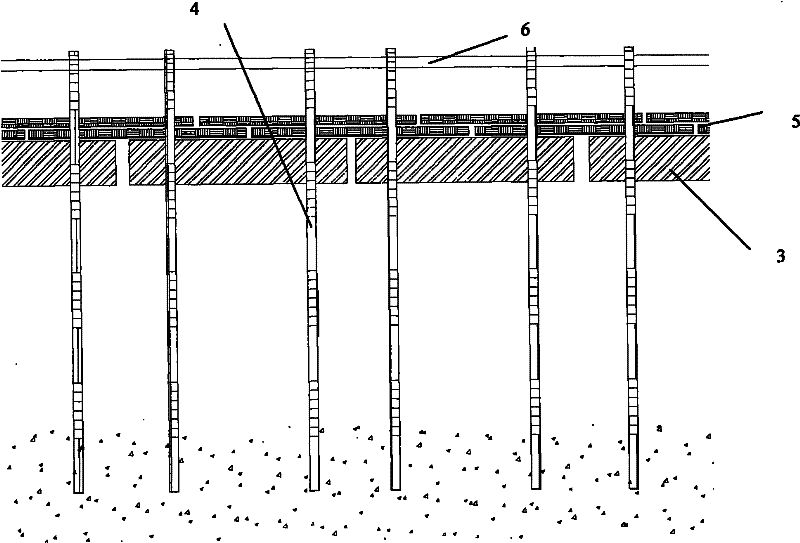

[0041] (4) four moso bamboo poles are set up as column 4 at each rubber foam board 3 both sides, and the lower end passes through the blow-fill thickness and enters the hard soil layer 50cm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com