Pipeline aperture deformer for trenchless pipeline laying

A non-excavation, deformation instrument technology, applied in the direction of instruments, measuring devices, using fluid devices, etc., to achieve the effect of convenient control operation and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

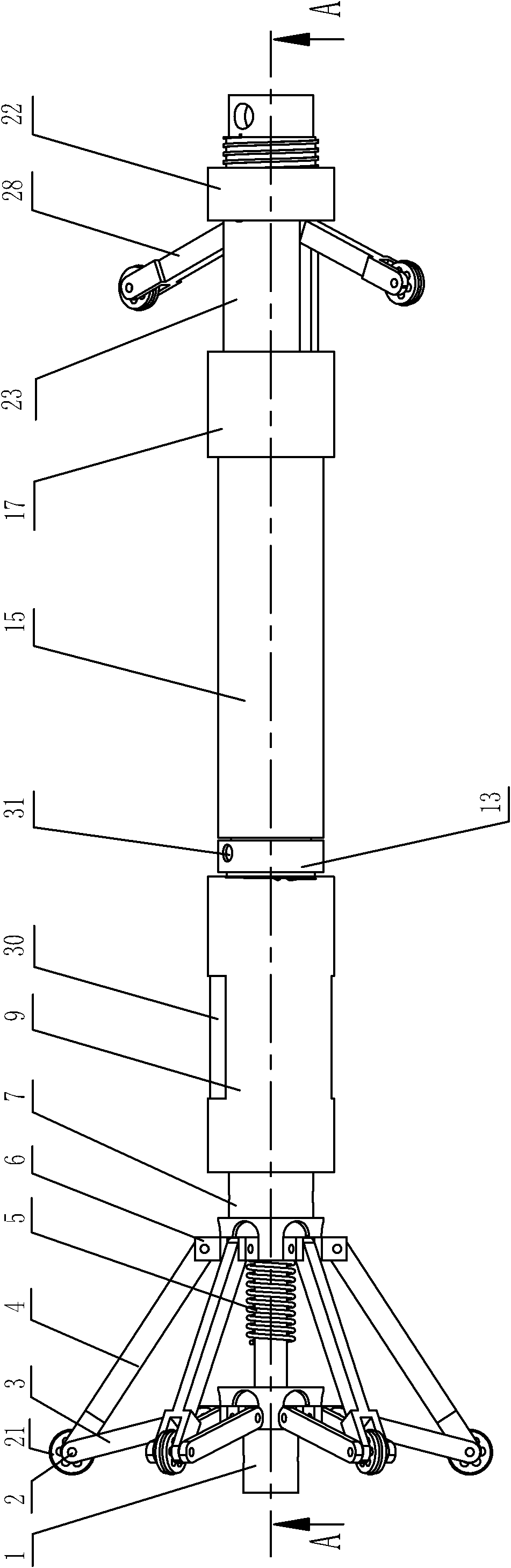

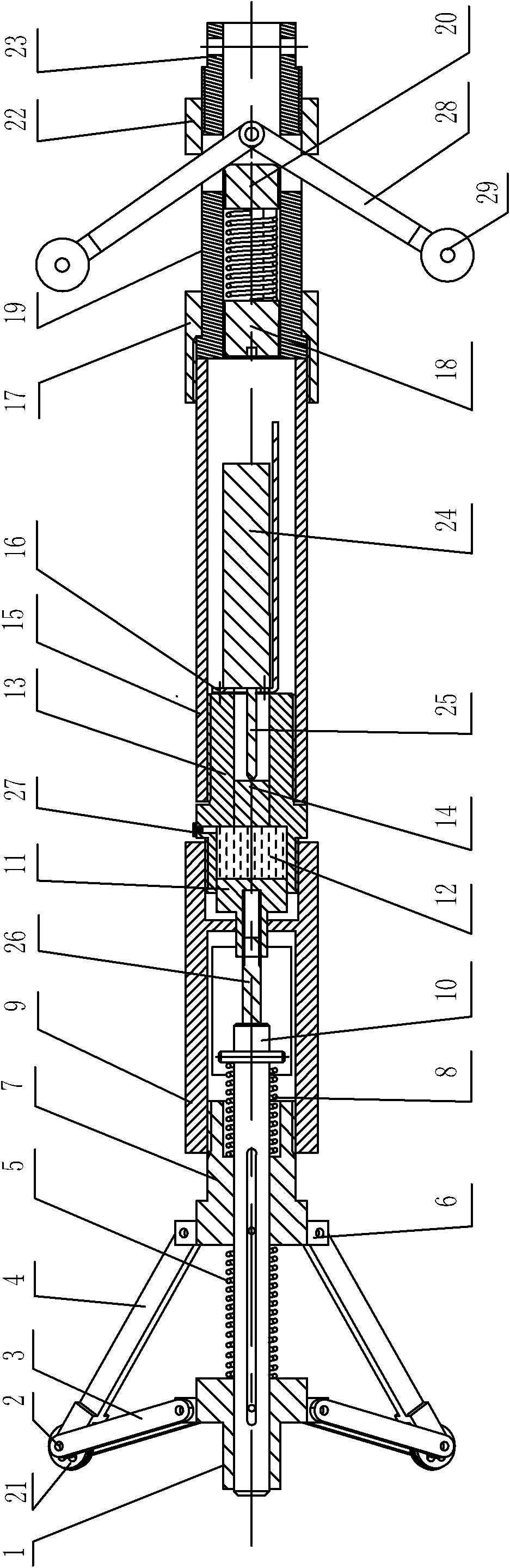

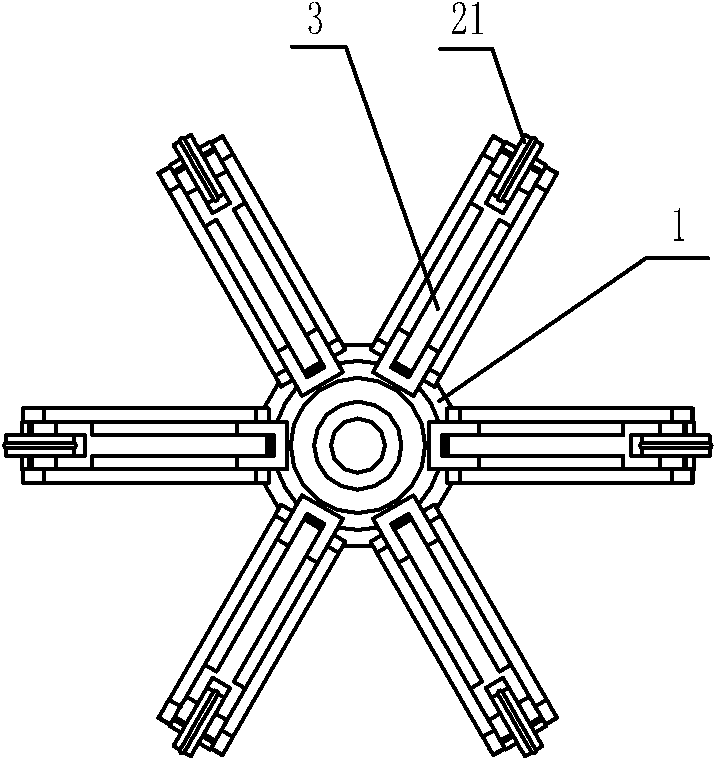

[0025] Such as figure 1 , figure 2 , image 3 , Figure 7 , Figure 8 , Figure 9 As shown, the non-excavation pipe laying pipeline aperture deformation instrument, it includes deformation frame 35, transfer rod 26, oil cylinder amplification mechanism, displacement sensor, sensor chamber 15, centralizer 36; The right end of the connecting cylinder 9 of the frame is fixedly connected (such as threaded connection or welding, figure 2 The left side is left, and the right is right), the large piston 11 of the oil cylinder amplification mechanism is fixedly connected (as threaded or welded) with the right end of the mandrel 10 of the deformation frame by the transfer rod 26, and the right end of the oil cylinder block 13 of the oil cylinder amplification mechanism and the left end of the sensor chamber 15 are fixedly connected (such as threaded connection or welding); the displacement sensor 24 is located in the sensor chamber 15, and the displacement sensor 24 is fixed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com