Arc end tooth gauge inspection and adjustment device

A technology of adjusting device and arc end teeth, which is applied to measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of low positioning accuracy, wear of the worktable, inability to guarantee positioning requirements, etc., and achieves obvious effects and adjustment accuracy. High, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

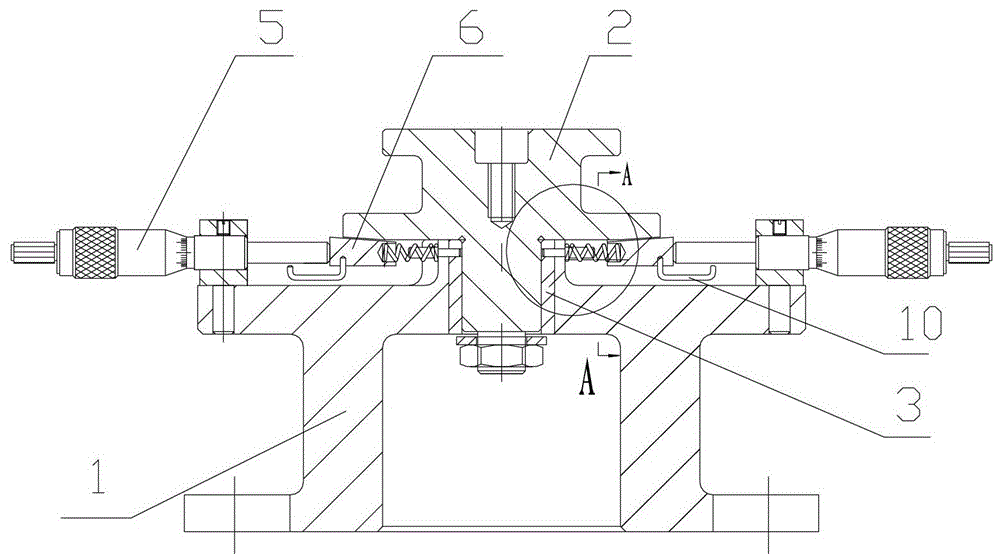

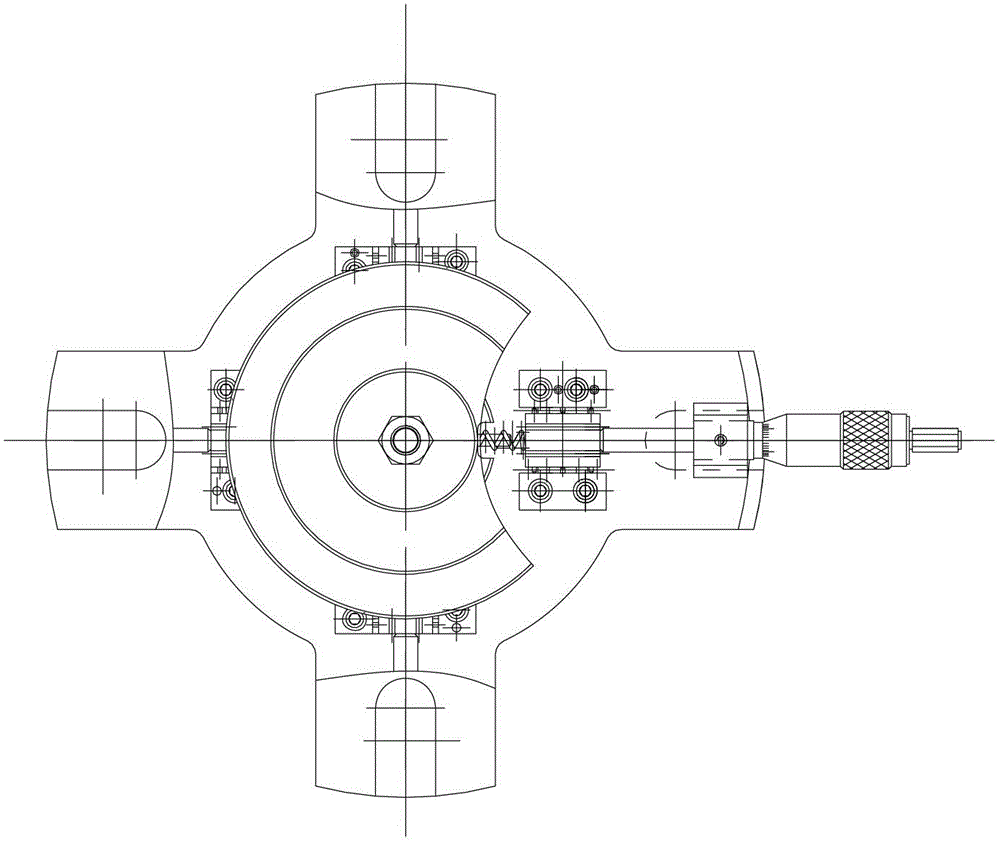

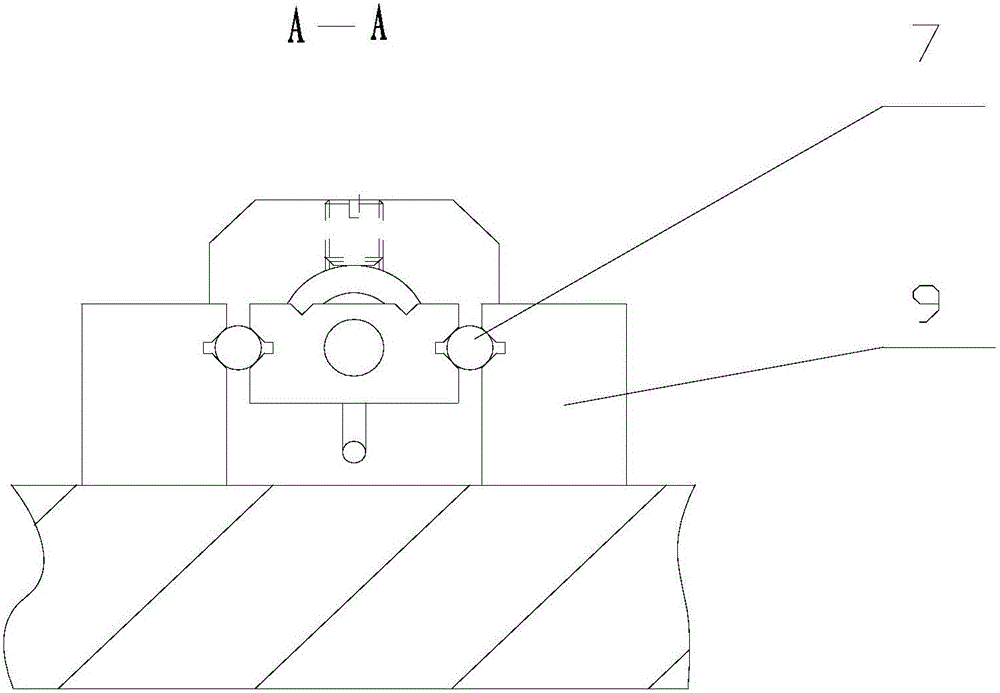

[0013] As shown in the figure: the arc-end tooth gauge inspection and adjustment device includes a base 1, a positioning shaft 2, a shaft sleeve 3, and 4 uniformly distributed fine-tuning mechanisms with the same structure. The base is provided with holes and the sleeve is fixed by positioning pins 4. 3. There is a step on the positioning shaft 2, and a small-angle conical surface is provided on the step. The positioning shaft 2 is installed on the bushing 3 with clearance. The fine-tuning mechanism includes a micrometer 5, a sliding plate 6 with an angled surface, and a guide rail 9 , roller bearing 7 and compression spring 8, described micrometer 5 is installed on the base, the fine-tuning head top on the micrometer 5 is on the slide plate, and the angle surface of slide plate 6 is identical with the angle of the small-angle taper surface of positioning shaft 2 and Cooperate with each other, V-shaped guide grooves are provided on both sides of the slide plate 6, and the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com