Online slurry densimeter and measuring method thereof

A technology of density meter and slurry, which is applied in the direction of measuring device, specific gravity measurement, instrument, etc., can solve the problems of insufficient measurement accuracy, poor real-time performance, and high price of tomographic imaging technology, and achieve the effect of improving dimensional accuracy and translation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Next, the technical scheme in the embodiment of the present invention will be described in conjunction with the embodiment of the present invention, and is clearly, and it is clear that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor.

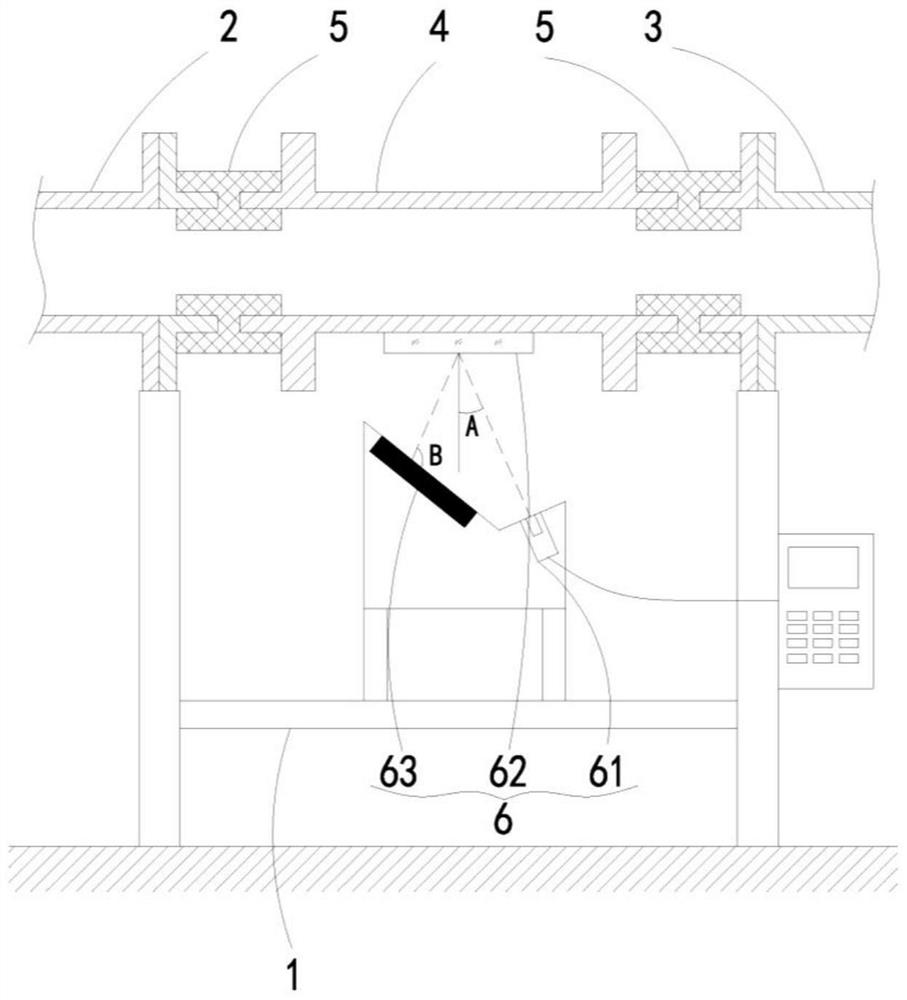

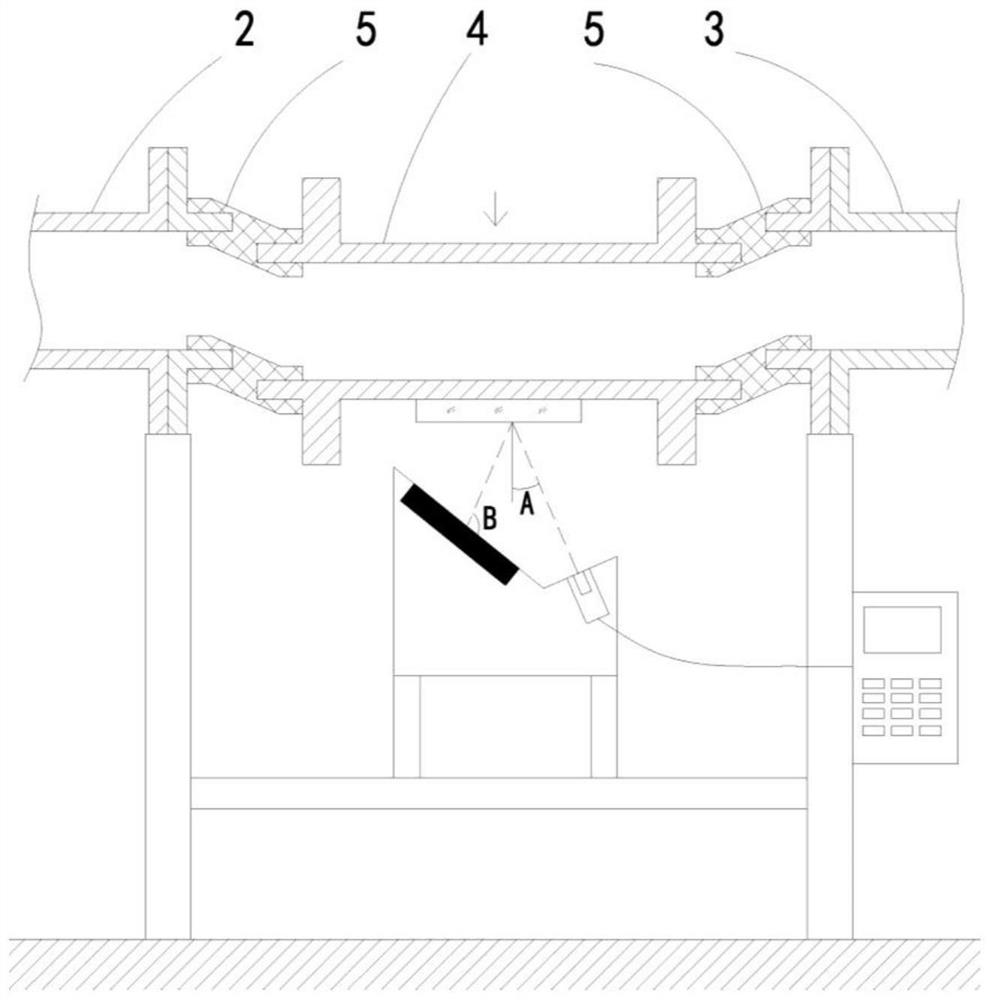

[0034] Such as figure 1 Combine figure 2 As shown, the present invention provides a linear bodies, specifically includes a bracket 1, a first conduit 2, a second conduit 3, an intermediate conduit 4, two flexible joint sections 5, and a variable detection unit 6, or the like;

[0035] The bracket 1 is fixedly disposed on the ground, extending toward the horizontal direction and extends vertically toward the direction away from the ground; the bracket 1 is hollow; the stent 1 is used to hold up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com