Method of measuring tobacco shred filling value on line

A technology of filling value and shredded tobacco, which is applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of large dispersion of shredded tobacco filling value, large error of shredded tobacco filling value, complex detection process, etc., and achieve harmless online measurement, accurate online measurement, The effect of simplifying the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 On-line measurement of filling value of shredded stems

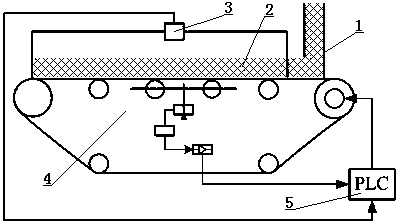

[0028] according to figure 1 In the structure shown, a complete set of equipment for model establishment is set up at the online measurement point of the cut stem filling value, including a quantitative device 1 , a weighing device 4 , and a control processor 5 . The cut stem 2 to be tested passes through the quantitative device 1 and the weighing device 4 successively, and the flow rate of the cut stem 2 is V / T 0 , choose 330kg / h cut stems in this embodiment, take a certain time 30s as the detection interval, use a weighing device to take every second as a detection unit, constantly detect the instantaneous weight of cut stems, and record it as m 1 、m 2 ......m n ; Then get the average weight m within 30s 均 .

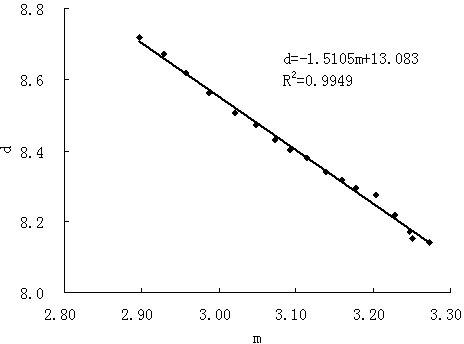

[0029] Define d as the filling value, laboratory test weight m 均 Corresponding stem filling value d, get d and m 均 The related formula, d=-1.5105m 均 +13.0830, wherein, the model coefficie...

Embodiment 2

[0034] Example 2 On-line measurement and moisture correction of shredded leaf filling value

[0035] according to figure 1 In the structure shown, a complete set of equipment for model establishment is set up at the online measurement point of the shredded filling value, including a quantitative device 1, an infrared moisture meter 3, a weighing device 4, and a control processor 5. The shredded leaf 2 to be measured passes through the quantitative device 1 and the weighing device 3 in sequence, and the flow rate of the shredded leaf 2 is V / T 0 , choose 4800kg / h shredded leaf in the present embodiment, take certain time 30s as detection interval, utilize weighing device to take every second as a detection unit, constantly detect the instantaneous weight and the instantaneous water content of shredded leaf, and record as m 1 、m 2 ......m n and S 1 , S 2 ... S n ; Then get the average weight m within 30s 均 and mean moisture content S 均 .

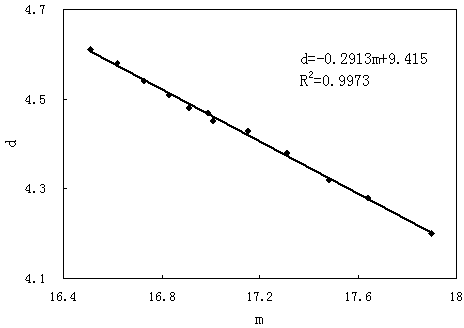

[0036] Define d as the filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com