High-sensitive multifunction analyser based on back light scattering technology

An analyzer and backward light technology, applied in the field of light scattering detection instruments, can solve problems such as sensitivity only reaching 10ppb, unfavorable sensor miniaturization, detection sensitivity limitation, etc., and achieve the effects of simple structure, reduced cost, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

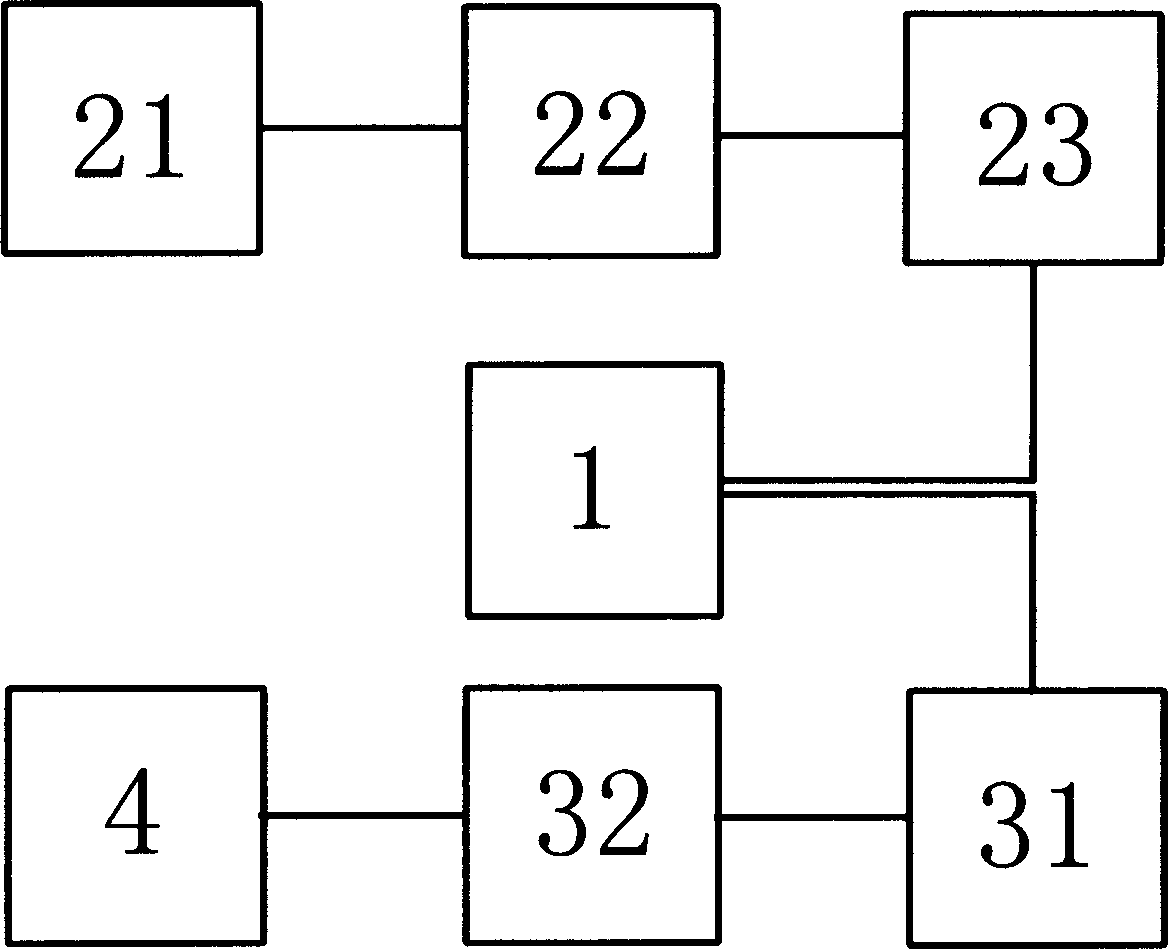

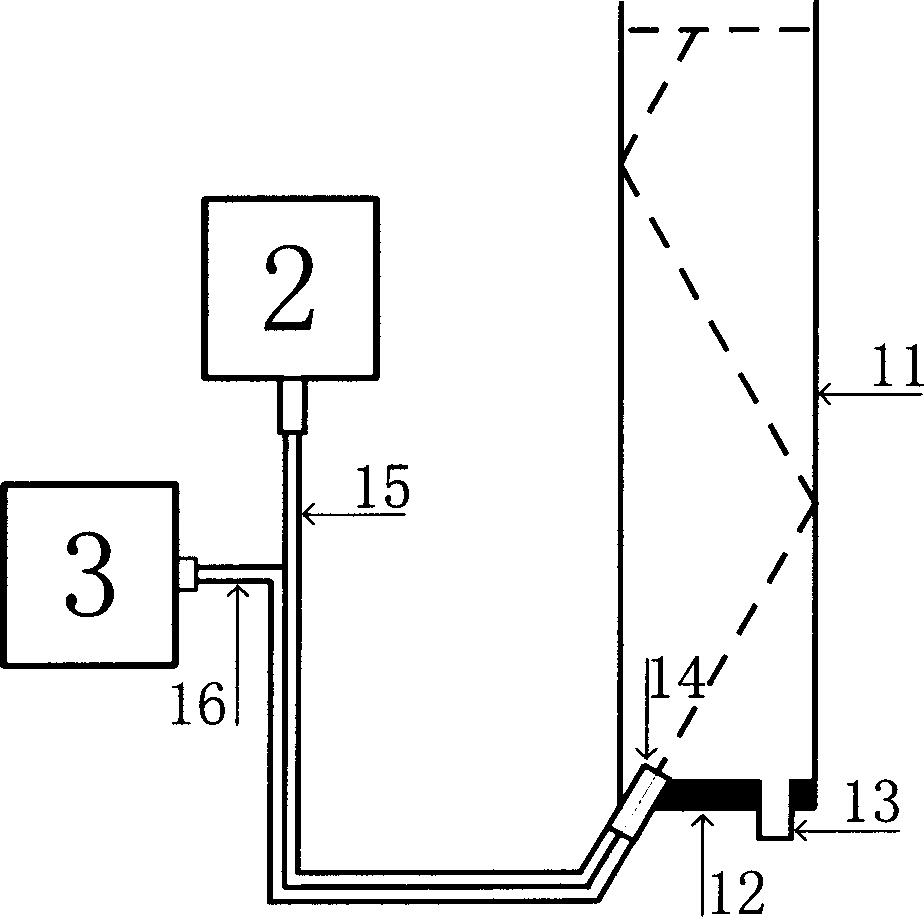

[0034] see figure 1 and figure 2 , the instrument of the present invention is made up of following several parts:

[0035] Detection probe: a cylinder or a square cylinder with a smooth inner surface of a certain height and a base 12 are glued together to form a liquid container 11; the light source and the signal transmission part are composed of two groups of optical fibers, one group is the excitation optical fiber group 15, and the other One group is the detection signal transmission fiber group 16 . Two groups of optical fibers are combined together, respectively coupled to the light source part 2 and the signal detection and amplification part 3 to form a nearly 180-degree backward light scattering analysis and testing system to achieve sensitive measurement of low-concentration substances.

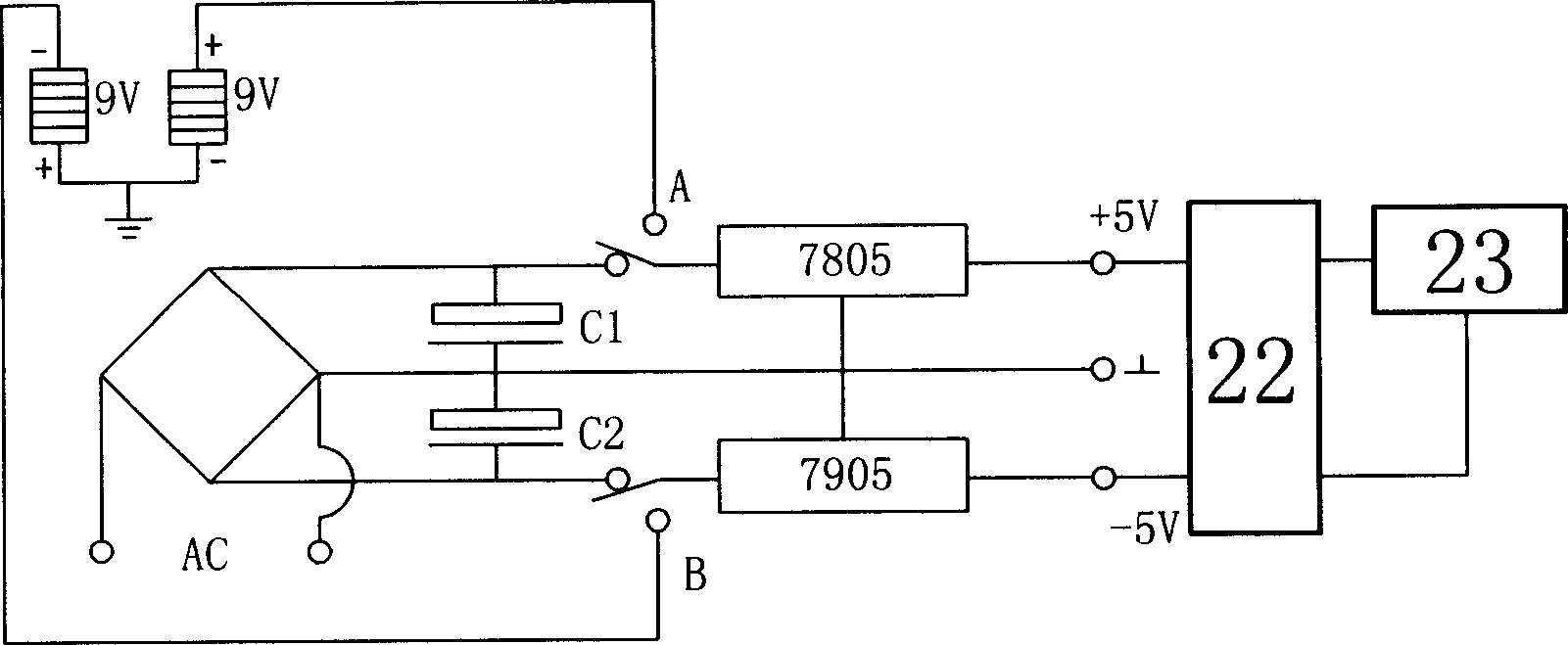

[0036] Light source part 2. Using a semiconductor laser 23 as an excitation light source, a power stabilization circuit 22 is connected between the power supply 21 and the semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com