NDIR gas sensor system and temperature and humidity compensation method thereof

A technology of gas sensor and temperature and humidity compensation, which is applied in the field of NDIR gas sensor, can solve the problems of unfavorable sensor miniaturization, unfavorable sensor miniaturization, insufficient gas absorption, etc., and achieve the elimination of light source jitter, accurate real-time measurement of concentration, and small structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

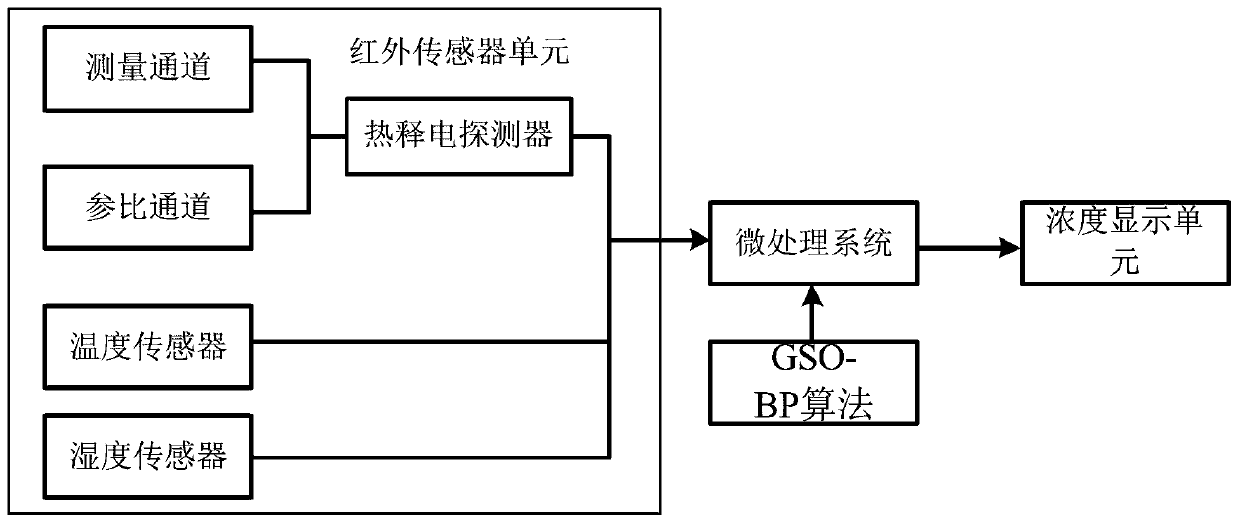

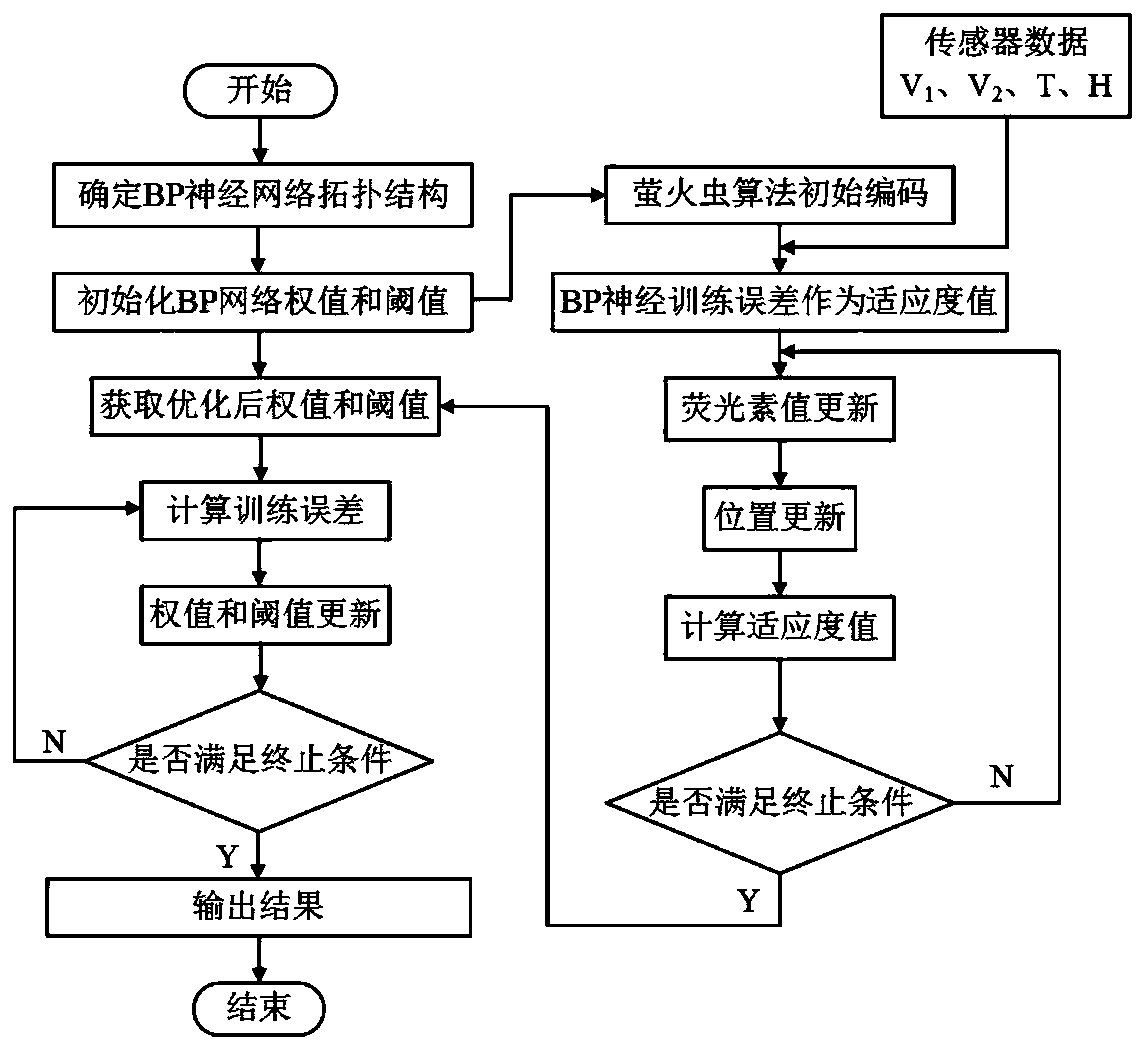

[0042] A kind of NDIR gas sensor system of the present invention, specific structure is as figure 1 As shown, it includes an infrared sensor unit, a microprocessor and a concentration display unit, and the microprocessing system is respectively connected with the infrared sensor unit and the concentration display unit; the microprocessing system is embedded with a GSO-BP neural network algorithm.

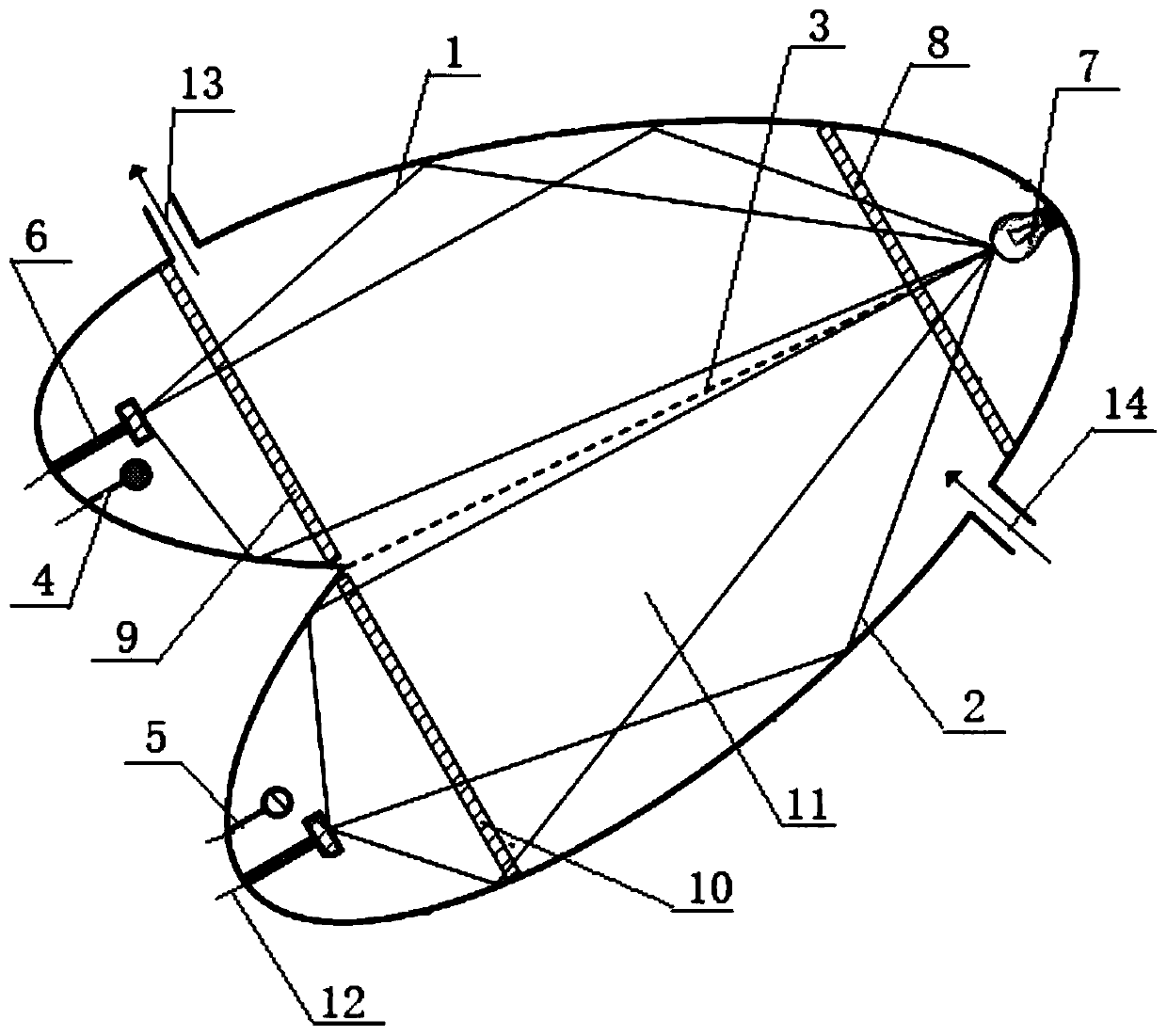

[0043] The concrete structure of infrared sensor unit of the present invention is as figure 2As shown, the infrared gas sensor of the present invention adopts a structural design of a single light source and two optical paths, including a measurement channel 1 and a reference channel 2, and specifically includes a sampling gas chamber 3 of the infrared sensor, a temperature sensor 4, a humidity sensor 5, and two pyrothermal sensors. Electrical dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com