Swing type measuring head robot online measuring system for BIW dimension detection

A size detection and measurement system technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of large position and posture constraints of the measuring head and large influence of ambient light, and achieve stable online measurement, large data volume, and stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

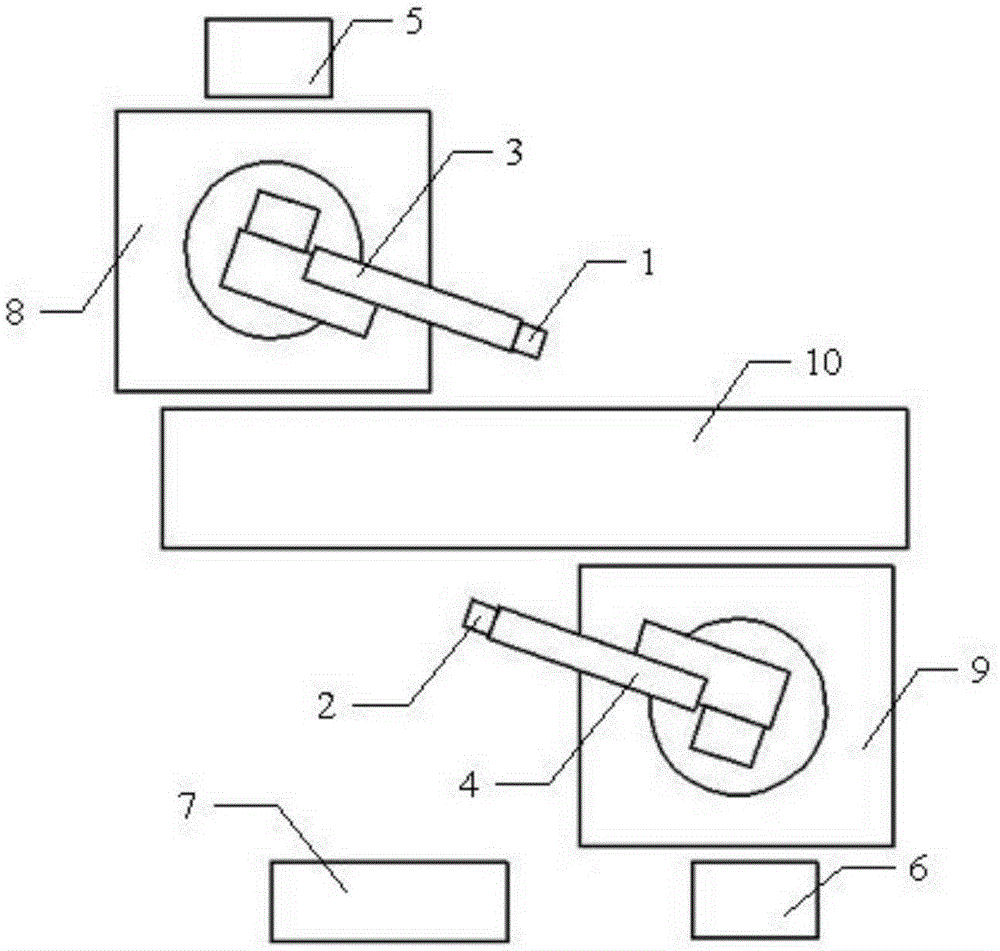

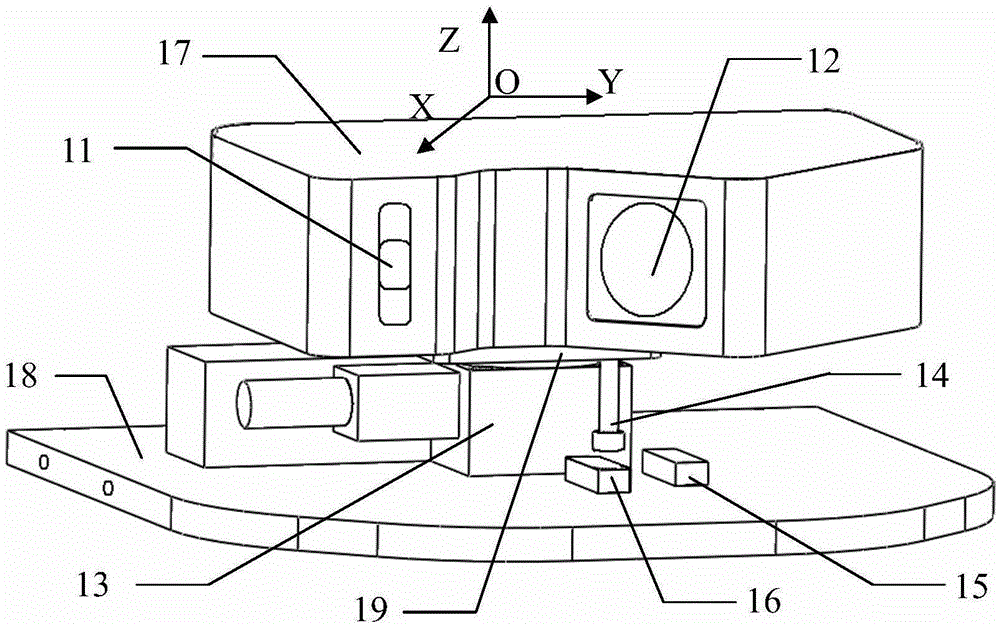

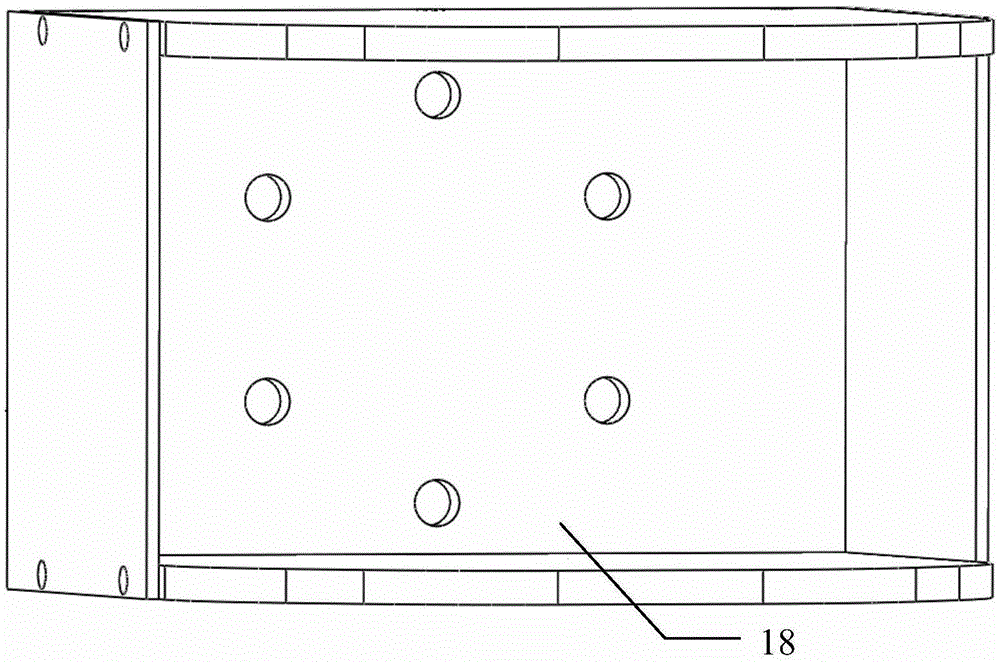

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, the present invention includes a first swing measuring head 1, a second swing measuring head 2, a first six-axis robot 3, a second six-axis robot 4, a first robot control cabinet 5, a second robot control cabinet 6, System control cabinet 7 , first measurement base 8 , second measurement base 9 and body-in-white positioning tool base 10 . Among them, the first oscillating measuring head 1 and the second oscillating measuring head 2 are composed of a line laser projector 11, a monocular camera 12, a single-axis turntable 13, a limit block 14, a No. 1 photoelectric limiter 15, a No. 2 Photoelectric limiter 16, installation box 17, outer protective cover 18 and connection block 19 are formed. Outer protective cover 18 is a metal shell that is made of base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com