High precision angle-measuring method

A high-precision, angle measurement technology, applied in the field of angle measurement, can solve the problems that the angle measurement accuracy cannot meet the requirements of use, cannot meet the requirements of large load measurement, and the angle measurement range is small, so as to achieve large load measurement, the method is simple, The effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

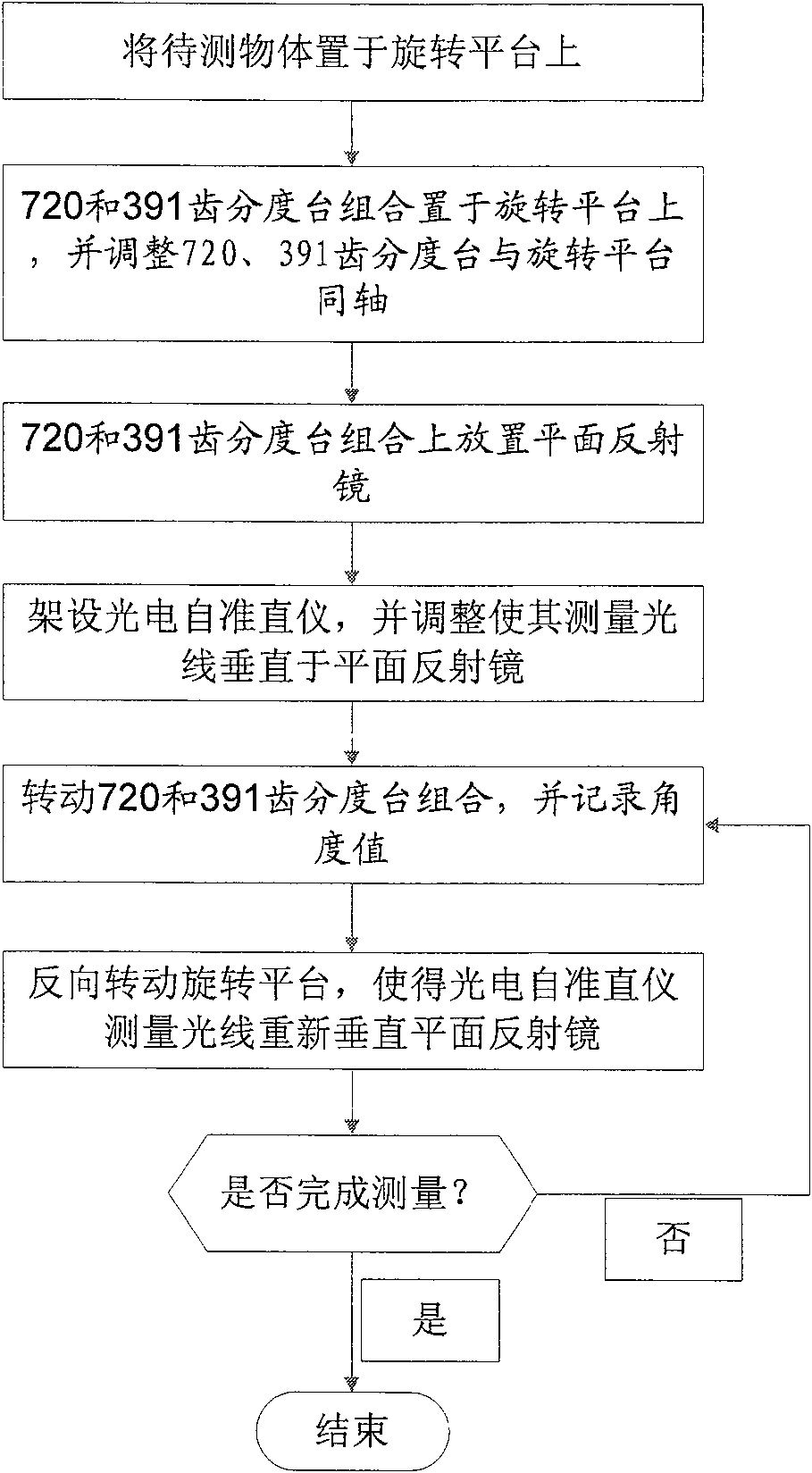

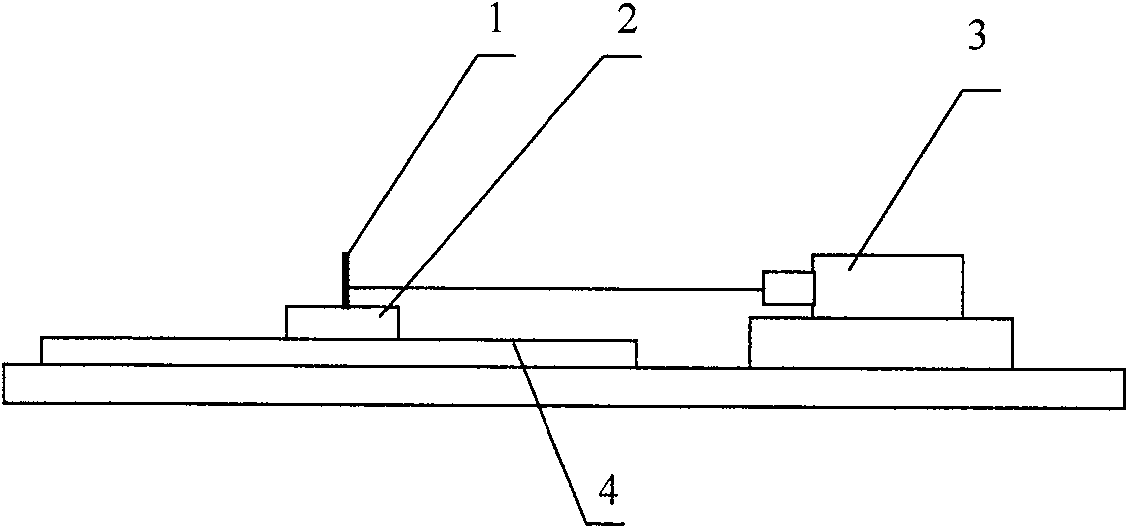

[0024] Such as figure 1 Shown is the flowchart block diagram of angle measuring method of the present invention, figure 2 It is a structural diagram of the angle measuring device used in the method of the present invention, wherein 1 is a plane mirror, 2 is a combination of a 720-tooth indexing table and a 391-tooth indexing table, 3 is a photoelectric autocollimator, and 4 is a rotating platform. The rotating platform provides rotation and bearing functions, and the angle measurement function is realized by the combination of 720-tooth indexing table and 391-tooth indexing table and photoelectric autocollimator. Place the object to be measured on the rotating platform, and its position can be selected arbitrarily. Put the combination of the 720-tooth indexing table and the 391-tooth indexing table on the rotating platform, and place it on the combination of the 720-tooth indexing table and the 391-tooth indexing table. Place the plane reflector so that the horizontal rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com