Instrumentation indentation test method for elastic-plastic parameters of material based on single Vickers pressure head

An instrumented indentation, elastic-plastic technique, applied in the direction of testing the strength of materials using a stable tension/compression

Inactive Publication Date: 2013-11-27

ACADEMY OF ARMORED FORCES ENG PLA

View PDF1 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The object of the present invention is to provide a kind of material elastoplastic parameter instrumentation indentation test method based on a single Vickers indenter, to solve the problem of determining the strain of me

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Login to View More

Abstract

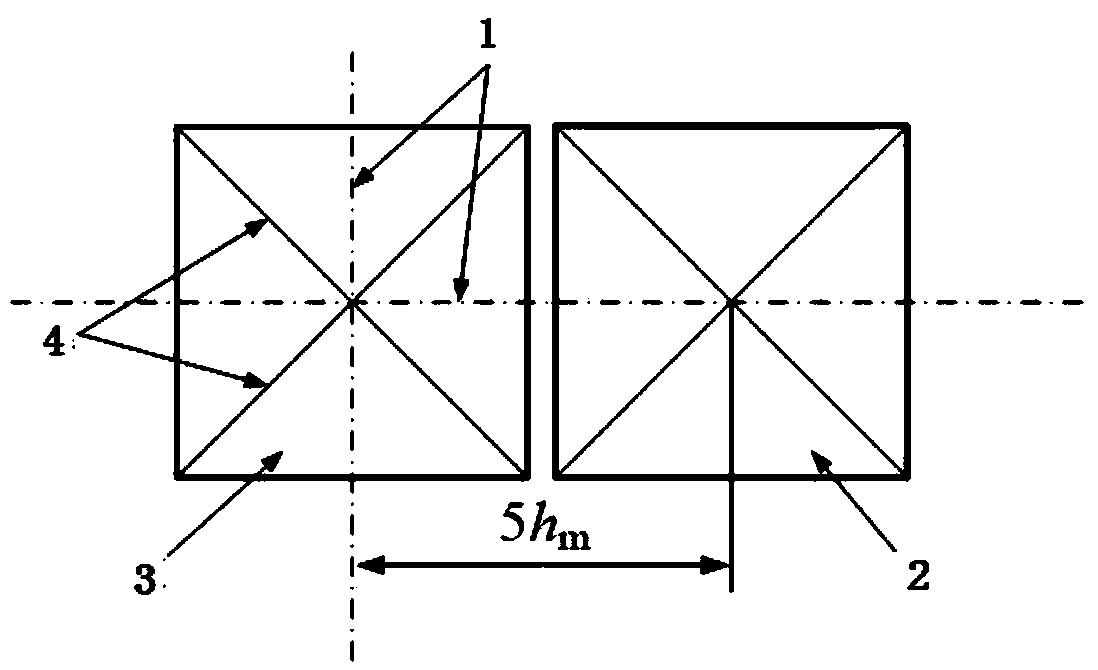

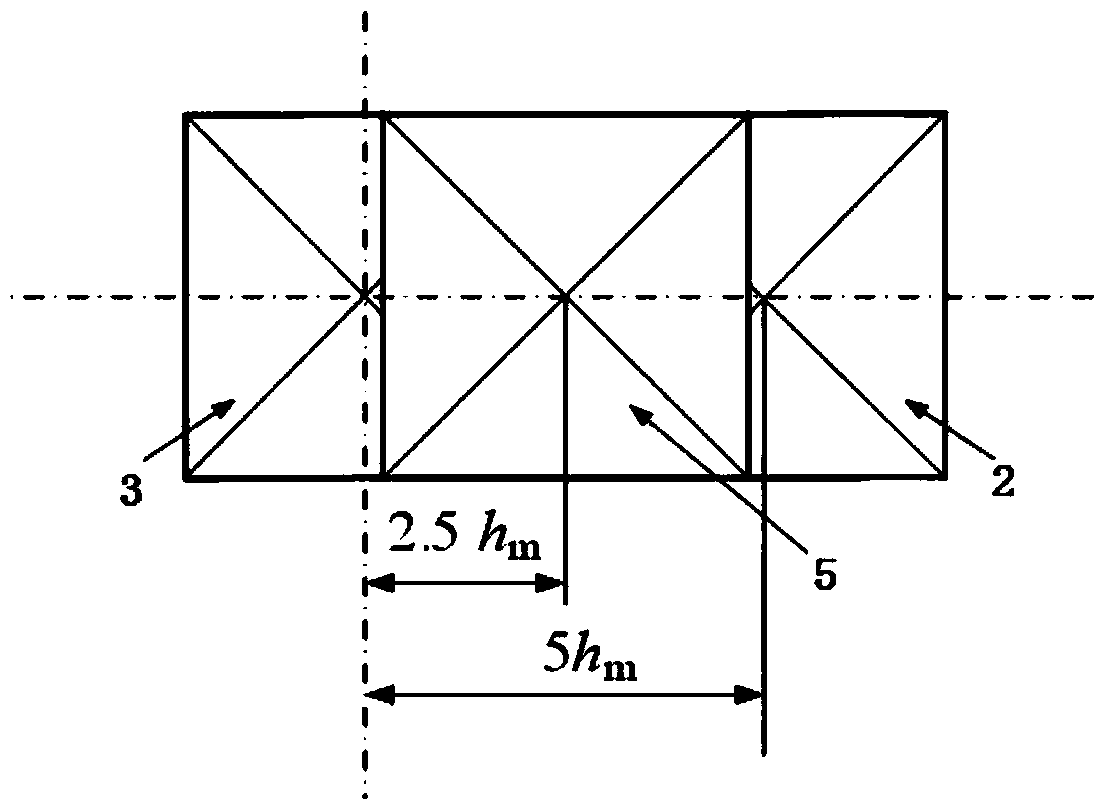

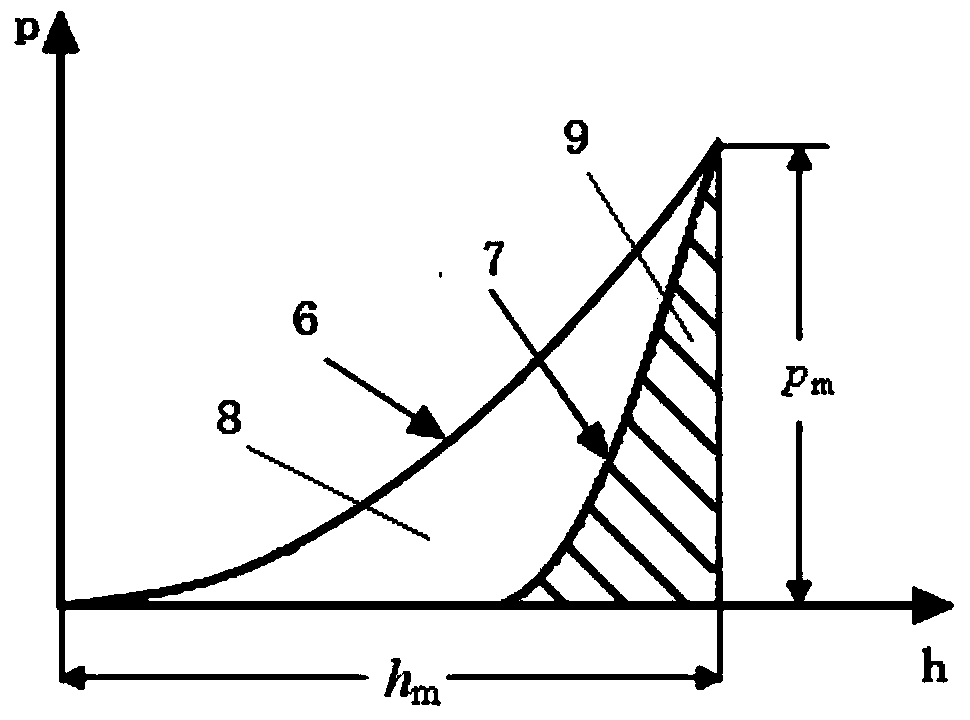

The invention discloses an instrumentation indentation test method for elastic-plastic parameters of a material based on a single Vickers pressure head. According to the method, the strain hardening exponent, elasticity modulus and offset yield strength sigma 0.2 of the metal material are determined by virtue of three instrumentation indentation load-depth curves in which indentation positions have special aggregation manners. The method has the advantages that the strain hardening exponent, elasticity modulus and offset yield strength sigma 0.2 of the metal material can be tested only by virtue of the single diamond Vickers pressure head; the high-precision test on the elasticity modulus of the material can be realized based on the tested strain hardening exponent of the material; the indentation positions of the three instrumentation indentation have aggregation properties, and the elastic-plastic parameters of the microcell material can be tested.

Description

technical field [0001] The invention belongs to the field of testing mechanical properties of materials. It specifically relates to a method of testing the strain hardening exponent, modulus of elasticity and conditional yield strength σ of metallic materials using an instrumented indenter and a single Vickers indenter. 0.2 Methods. Background technique [0002] The instrumented indentation test technology obtains the indentation load-depth curve by synchronously measuring the indentation load acting on the diamond indenter and the indentation depth of the diamond indenter into the surface of the tested material in real time. The dimensionless functional relationship between the mechanical property parameters of the measured material can identify many mechanical property parameters of the measured material. [0003] The instrumented indentation test of the elastic modulus of materials mainly includes the "Oliver-Pharr method" or "slope method" proposed by W.C.Oliver and G....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08

Inventor 马德军陈伟

Owner ACADEMY OF ARMORED FORCES ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com