Multi-spectral optical axis parallelism testing device and testing method

A testing device and a multi-spectral technology, which are applied in the field of optical detection, can solve the problem of not being able to meet the optical axis testing of multi-spectral optoelectronic equipment and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with accompanying drawing.

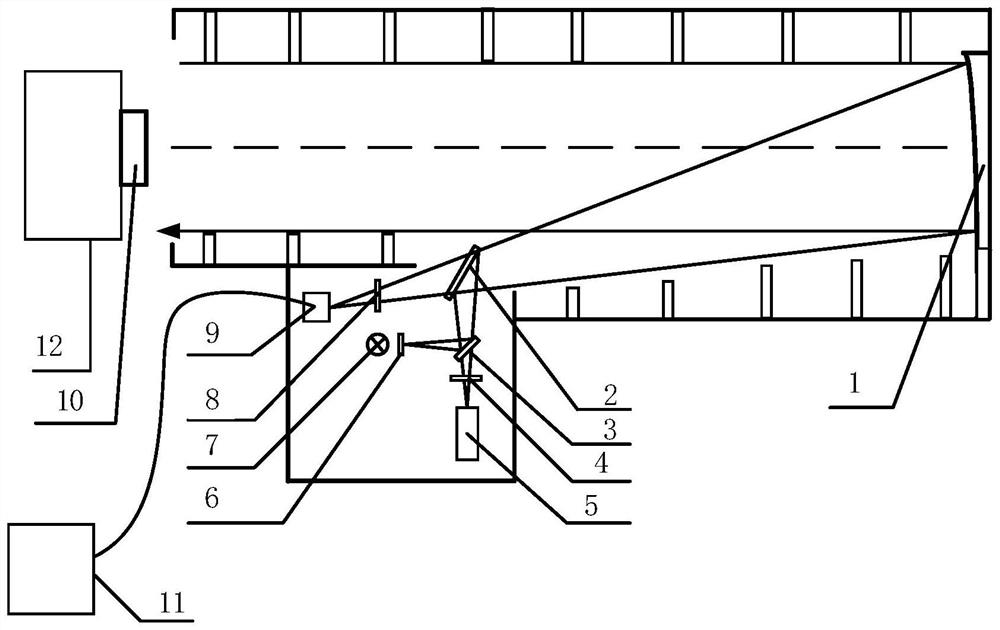

[0077] Such as figure 1 As shown, the multi-spectral optical axis parallelism test device provided by the present invention includes a wide-spectrum target alignment module, a multi-spectral target generation module, a laser spot acquisition module, an image analysis module and a reference mirror 10 .

[0078] The multi-spectral target generation module is used to simulate targets of different spectral bands, including the first attenuation film 4, the laser light source 5, the target target 6, the wide-spectrum light source 7 and the second beam splitter 3, wherein: the first attenuation film 4 is set On the output light path of the laser light source 5, the first attenuation plate 4 and the laser light source 5 are used to simulate the laser ranging band target; the target target 6 is arranged on the output light path of the wide-spectrum light source 7, and the target ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com