Die-casting aluminum alloy micro-arc oxidation electrolyte and method thereof as well as product

A technology of micro-arc oxidation and cast aluminum alloy, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of poor corrosion resistance of the film, loose film, coarse particles of the film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment of the micro-arc oxidation of the die-casting aluminum alloy of the present invention is given below.

[0024] The die-casting aluminum alloy trial production piece is made of die-casting aluminum alloy ADC12, and the size of the die-casting aluminum alloy trial production piece is 110*70*1.5mm. Then, the trial piece is fully degreased and degreased. Usually, the trial piece is put into a cleaning agent with acetone and absolute ethanol as components, and cleaned in an ultrasonic cleaning agent for 5-10 minutes. Then put it into an oven, and dry the trial production sheet at a temperature of 120° C. for later use.

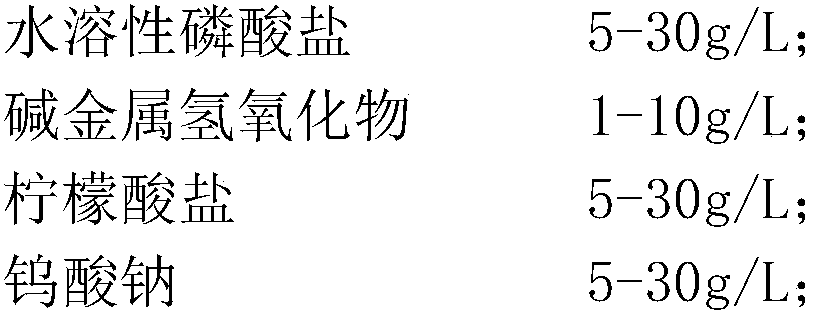

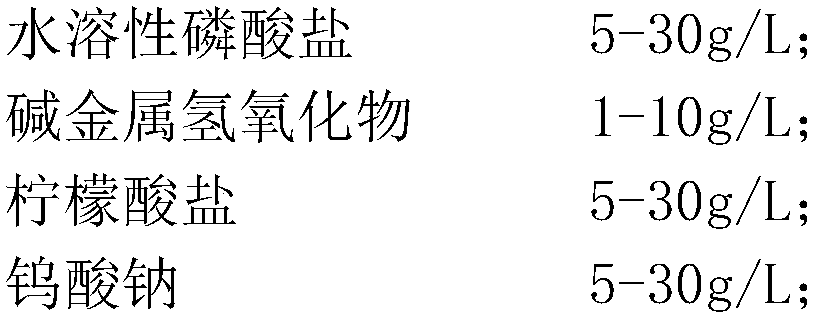

[0025] Prepare micro-arc oxidation solution, the present embodiment selects the sodium phosphate of 10g / L, the sodium hydroxide of 8g / L, the sodium citrate of 12g / L, the sodium tungstate of 10g / L, diethylenetriamine and triethanolamine press 4 : 1 of the mixed solution prepared in the ratio of 10-40g / L, mixed and stirred according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com