Wear-resistant high holding precision rolling rear working roller and production method thereof

A manufacturing method and technology of work rolls, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of poor roll shape retention, poor wear resistance, increased wear, etc., achieve uniform distribution control, and solve surface problems. Roughness problem, improvement effect of carbide morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

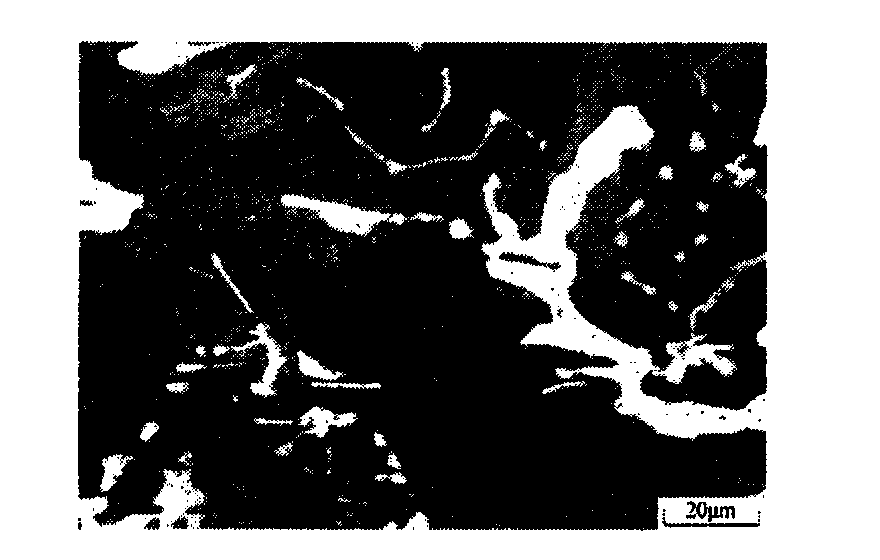

Image

Examples

Embodiment 1

[0023] A wear-resistant high-retention post-finishing work roll, the alloy components and weight percentages of the working layer are: C3.10%; Si0.50%, Mn0.6%, P0.05%, S0. 03%, Cr1.70%, Ni3.8%, Mo0.40%, W0.50%, V1.70%, the rest is Fe and unavoidable impurities; the roll core is ductile iron, and the manufacturing method of the work roll is :

[0024] ①Casting process: First, the working layer of the roll is poured by a horizontal centrifuge, and the core and roll neck are statically poured after the working layer is solidified. Centrifugal casting, first melt the molten iron of the working layer and the roller core material in the intermediate frequency melting furnace separately, when the molten iron of the two components meets the requirements, heat the molten iron separately, and when the temperature reaches the centrifugal pouring temperature, first put the molten iron in the working layer Put the molten iron into the pouring ladle and perform metamorphism treatment. Afte...

Embodiment 2~ Embodiment 5

[0031] The casting method of the wear-resistant high-maintenance post-finishing work rolls in the following examples is the same as that in Example 1. The composition content, heat treatment method and performance of the wear-resistant high-maintenance post-finishing work rolls are shown in Table 2. The column of actual use effect in Table 2 refers to the tonnage of steel that can be rolled when the diameter of the work roll is worn away by 1mm.

[0032] Table 2

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com