High-strength anti-corrosion Al-Zn-Mg-(Cu)-series aluminum alloy rod material and preparation method thereof

An aluminum alloy and corrosion-resistant technology, applied in the field of aluminum profiles, can solve problems such as restricted application, poor corrosion resistance, and aluminum needs to be improved, and achieve the effect of improving mechanical strength and corrosion resistance, and solving low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

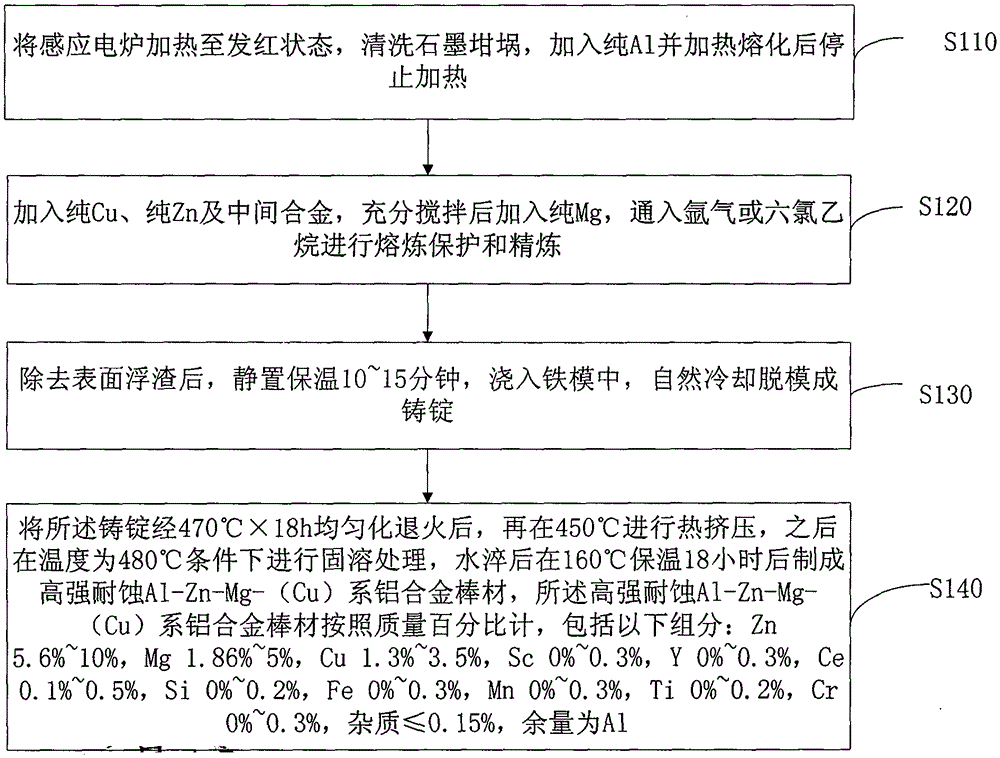

[0033] As shown in Figure 1, the preparation method of the high-strength corrosion-resistant Al-Zn-Mg-(Cu) series aluminum alloy rod of one embodiment includes:

[0034] S110, heating the induction furnace to a red state, cleaning the graphite crucible, adding pure Al and heating to melt, then stop heating;

[0035] S120, add pure Cu, pure Zn and intermediate alloy, add pure Mg after fully stirring, pass through argon or hexachloroethane for melting protection and refining;

[0036] S130, after removing the surface scum, leave it to stand for 10-15 minutes, pour it into an iron mold, and cool it naturally to form an ingot;

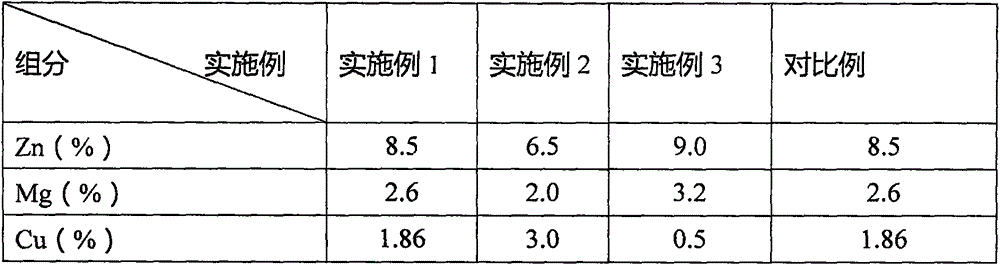

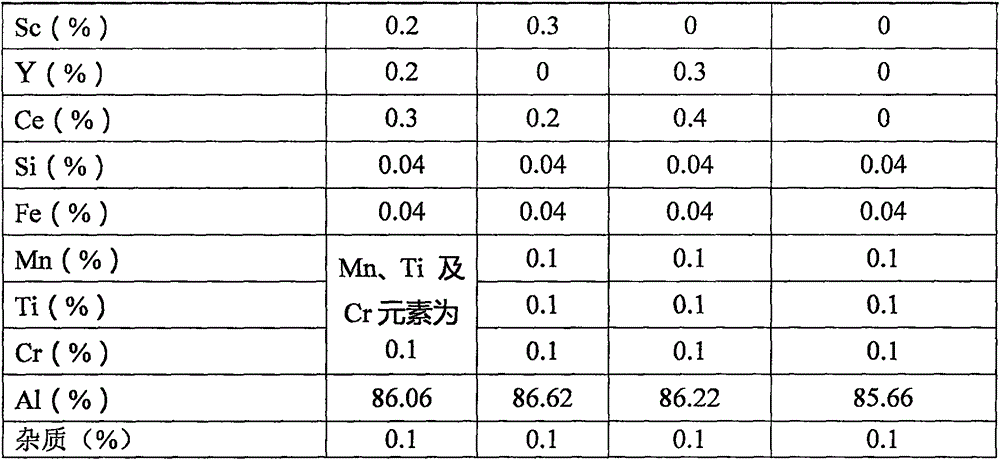

[0037] S140. After the ingot is homogenized and annealed at 470°C for 18 hours, hot extrusion is carried out at 450°C, and then solution treatment is carried out at a temperature of 480°C. After water quenching, the ingot is kept at 160°C for 18 hours. A high-strength and corrosion-resistant Al-Zn-Mg-(Cu) aluminum alloy rod is formed, and the high-strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com