Artificial leather adhesive and preparation method thereof

A technology for adhesives and artificial leather, applied in the direction of adhesives, adhesive additives, monocarboxylic acid ester copolymer adhesives, etc., can solve the problems of low comprehensive performance, general water resistance, and great adhesion by the environment, and achieve Effects of improving cohesion and bond strength, improving viscosity and hydrophobicity, improving durability and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

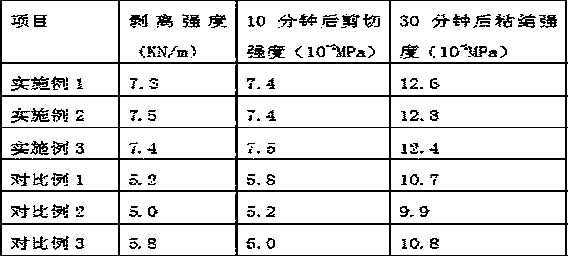

Examples

Embodiment 1

[0022] An adhesive for artificial leather, made of the following components in parts by weight: 72 parts of polyvinyl acetate, 11 parts of polydimethylsiloxane, 0.65 parts of potassium persulfate, γ-aminopropyl triethoxy 0.9 parts of silane, 2.8 parts of hydroxyethyl methylcellulose, 1.1 parts of sodium sulfate, 1.6 parts of magnesium chloride, 5.5 parts of water glass, 4.2 parts of triethanolamine, 38 parts of acetone, 1.6 parts of H-66 surfactant, 75 parts of deionized water 13 parts, attapulgite clay.

[0023] The attapulgite is modified, and the specific steps are as follows:

[0024] (1) Surface activation treatment:

[0025] Put the attapulgite into a hydrochloric acid solution with a mass fraction of 5 times its weight and be 15%, filter it out after soaking for 15 minutes;

[0026] (2) Surface modification treatment:

[0027] Treat the attapulgite treated in step (1) at a high temperature of 565°C for 30 minutes, then cool it down to room temperature naturally, soak...

Embodiment 2

[0036] An adhesive for artificial leather, made of the following components in parts by weight: 74 parts of polyvinyl acetate, 12 parts of polydimethylsiloxane, 0.7 parts of potassium persulfate, γ-aminopropyl triethoxy 1 part of silane, 3.1 parts of hydroxyethyl methylcellulose, 1.0 parts of sodium sulfate, 1.7 parts of magnesium chloride, 5.6 parts of water glass, 4.8 parts of triethanolamine, 40 parts of acetone, 1.3 parts of H-66 surfactant, 77 parts of deionized water part, 14 parts of attapulgite.

[0037] The modification method of attapulgite is the same as in Example 1, and the preparation method of the adhesive is the same as in Example 1.

Embodiment 3

[0039] An adhesive for artificial leather, made of the following components in parts by weight: 73 parts of polyvinyl acetate, 11 parts of polydimethylsiloxane, 0.75 parts of potassium persulfate, γ-aminopropyl triethoxy 1.1 parts of silane, 3 parts of hydroxyethyl methylcellulose, 1.2 parts of sodium sulfate, 1.5 parts of magnesium chloride, 5.4 parts of water glass, 4.7 parts of triethanolamine, 42 parts of acetone, 1.3 parts of H-66 surfactant, 77 parts of deionized water part, 12 parts of attapulgite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com