Fuel cell bipolar plate and preparation method thereof

A fuel cell and bipolar plate technology, which is applied to fuel cells, fuel cell parts, circuits, etc., can solve the problems of shortened service life of bipolar plates, easy peeling of coatings, material corrosion, etc. The effect of compact shape and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

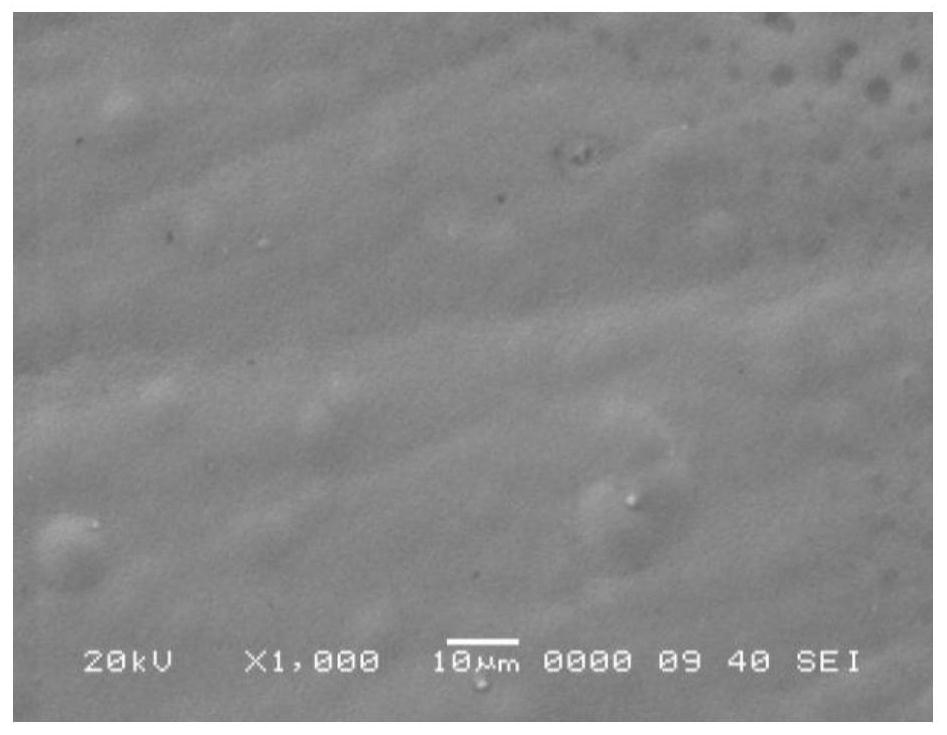

[0032] The metal substrate in this embodiment is a titanium plate, and the preparation process includes the following steps:

[0033] (1) Surface pretreatment of titanium sheet

[0034] Use 400#, 600#, 800# sandpaper to remove the oxide film on the surface of the titanium sheet, and then clean and activate the surface of the substrate: clean with acetone→clean with alcohol→clean with water→activate with palladium chloride solution for one minute. Pretreatment of the material can improve the bonding force of the coating and improve the quality of the coating, otherwise the coating may appear uneven or fall off.

[0035] (2) Nitrogen doping treatment

[0036] Put the titanium plate in the nitriding furnace for glow plasma nitrogen doping, the nitrogen doping gas is NH 3 , the high glow voltage is 700V, the current is 14A, the vacuum in the furnace is 150Pa, the nitriding temperature is 700°C, and the nitriding time is 2h; thus, nitrogen doping is performed on the surface of th...

Embodiment 2

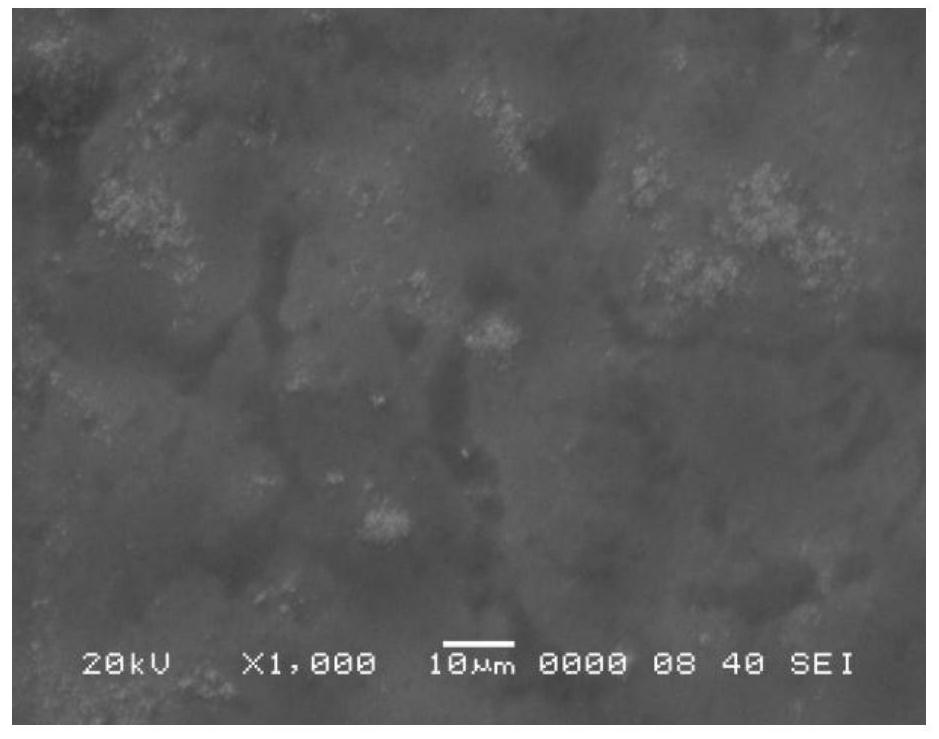

[0049] The preparation process of this example is basically the same as that of Example 1, except that the electroplating solution is heated to 55°C respectively, which is recorded as 55°C Ti / TiN / Ni-Cu.

Embodiment 3

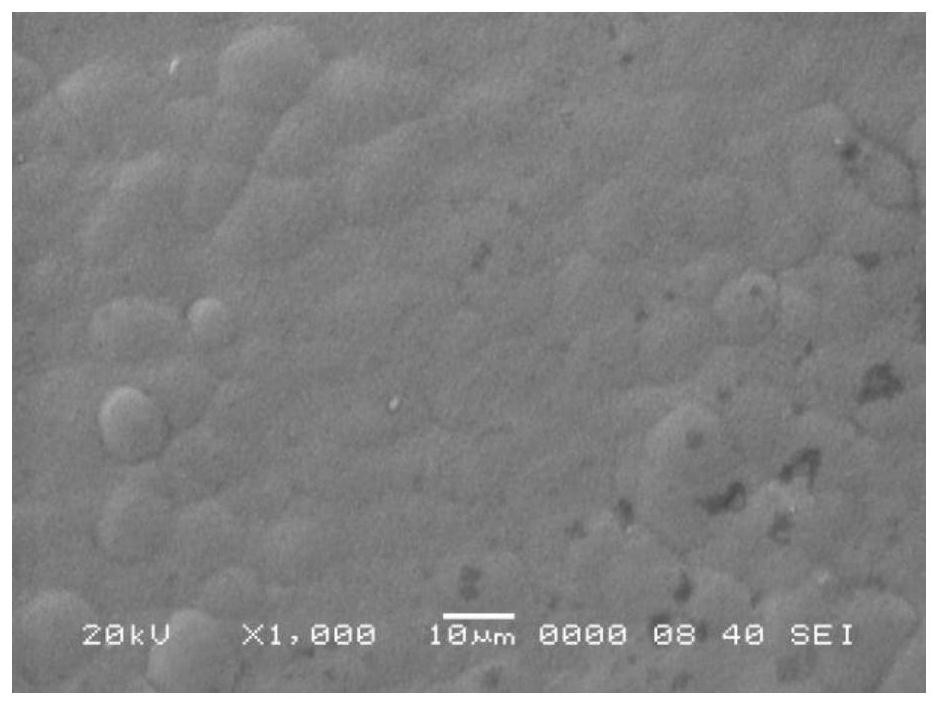

[0051] The preparation process of this example is basically the same as that of Example 1, except that the electroplating solution is heated to 65°C respectively, which is recorded as 65°C Ti / TiN / Ni-Cu.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com