Heating or cooling device and technique for high-purity rare earth liquor

A rare earth material liquid and cooling device technology, applied in the direction of improving process efficiency, can solve the problems of difficult automatic control and accurate control of material liquid temperature, limited service life of equipment, large equipment area, etc. The effect of large investment and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

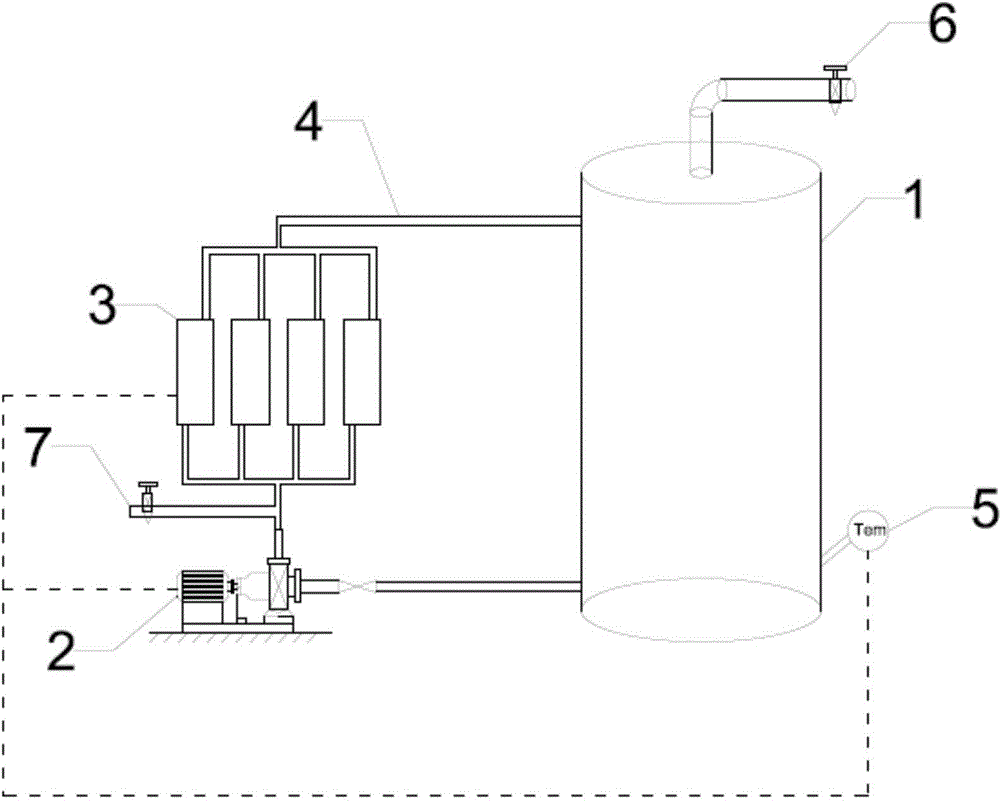

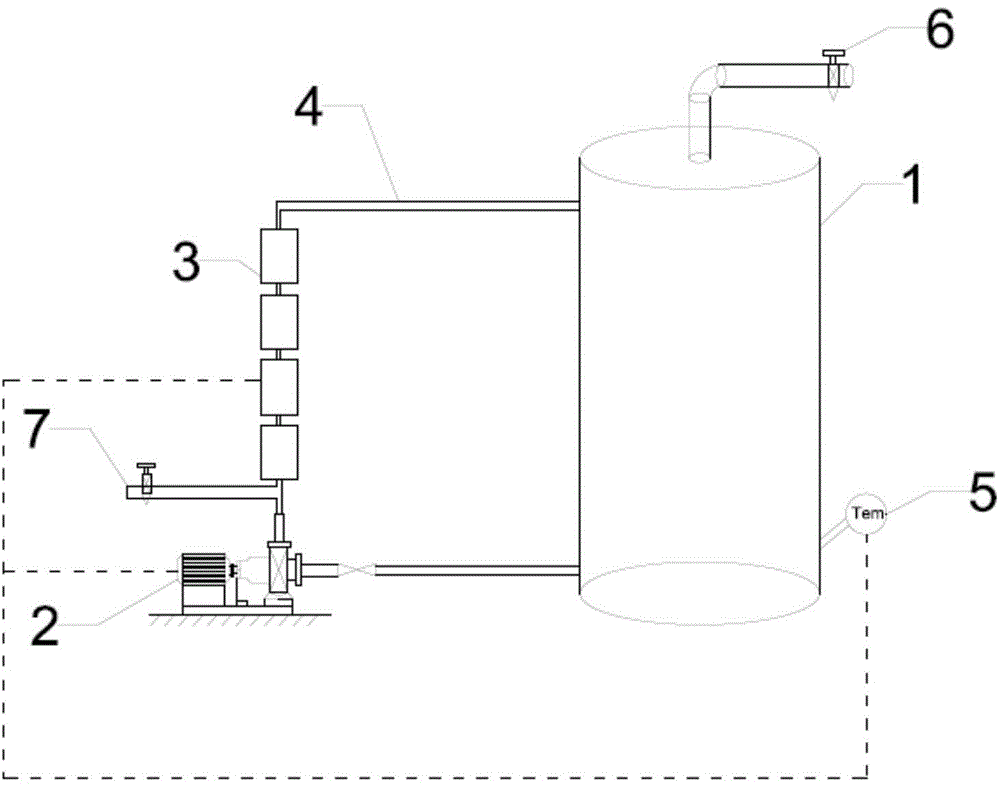

[0024] The high-purity rare earth chloride feed liquid passes through the interior of the graphite tube (3) repeatedly under the circulation of the circulation pump (2), and is heated externally by means of far infrared outside the graphite tube (3). The temperature control device (5) measures After warming, feed back to the circulating pump (2) to open it to control the temperature of the feed liquid at 60°C. After reaching the temperature, the circulating pump (2) stops, and the feed liquid is used for standby or pumped out through the outlet (7).

Embodiment 2

[0026] The high-purity rare-earth nitric acid feed solution passes through the interior of the graphite tube (3) repeatedly under the circulation of the circulating pump (2), and uses steam at about 150°C for external indirect heating on the outside of the graphite tube (3), and the temperature control device (5) measures After warming, feed back to the circulating pump (2) to turn it on to control the temperature of the feed liquid at 100°C. After reaching the temperature, the circulating pump (2) stops and the feed liquid is used for standby.

Embodiment 3

[0028] The high-purity chlorine nitrification rare earth material liquid pump passes through the interior of the graphite tube (3) under the circulation of the circulation pump (2), and the outside of the graphite tube is cooled by refrigerant. After the temperature control device (5) measures the temperature, it feeds back to the cooling The device and the circulation pump (2) can control the temperature of the feed liquid at -3°C. After reaching the temperature, the circulation pump (2) stops and the feed liquid is in standby.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com