Thick chromium-molybdenum steel plate for hydrogenation equipment and production method thereof

A technology of hydrogenation equipment and production methods, which is applied in metal processing equipment, rolling mill control devices, metal rolling, etc., can solve the problems of performance degradation and large-thickness steel plates that cannot meet performance parameters, and achieve increased strength, low cost, and The effect of saving alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

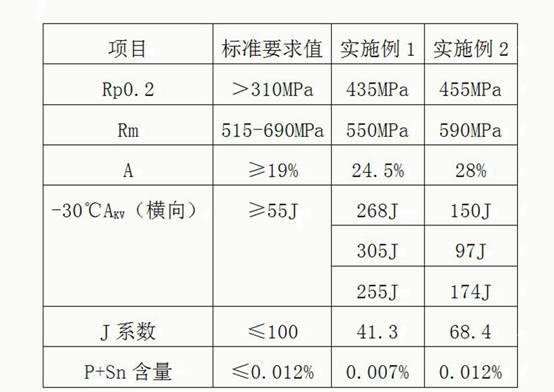

Embodiment 1

[0023] The large-thickness chromium-molybdenum steel plate for hydrogenation equipment in this embodiment is composed of the following components in weight percentage: C 0.13%, Si 0.06%, Mn 0.53%, P 0.005%, S 0.002%, Mo 0.98%, Ni 0.12 %, Cr 2.37%, Nb 0.013%, O 0.003%, N 0.007%, As 0.005%, Sn 0.002%, Sb 0.001%, Cu 0.05%, and the balance is Fe and unavoidable inclusions. The J coefficient of the large-thickness chromium-molybdenum steel plate for hydrogenation equipment in this embodiment is 41.3, the P+Sn content is 0.007%, and the thickness of the steel plate is 198mm.

[0024] The production method of the large-thickness chromium-molybdenum steel plate for the hydrogenation equipment of the present embodiment, the specific steps are:

[0025] (1) Smelting steps: Electroslag remelting is used for smelting. First, 100T ultra-high power electric arc furnace is used for smelting. During the melting period, a large amount of slag is used for slag flow operation, vacuum decarburiza...

Embodiment 2

[0029] The large-thickness chromium-molybdenum steel plate for hydrogenation equipment in this embodiment is composed of the following components in weight percentage: C 0.12%, Si 0.05%, Mn 0.52%, P 0.007%, S 0.003%, Mo 1.00%, Ni 0.12 %, Cr 2.35%, Nb 0.011%, O 0.002%, N 0.006%, As 0.008%, Sn 0.005%, Sb 0.001%, Cu 0.04%, the balance is Fe and unavoidable inclusions, the hydrogenation of this embodiment The J coefficient of the large thickness chromium molybdenum steel plate for equipment is 68.4, the P+Sn content is 0.012%, and the thickness of the steel plate is 195mm.

[0030] The production method of the large-thickness chromium-molybdenum steel plate for the hydrogenation equipment of the present embodiment, the specific steps are:

[0031] (1) Smelting steps: Electroslag remelting is used for smelting. First, 100T ultra-high power electric arc furnace is used for smelting. During the melting period, a large amount of slag is used for slag flow operation, vacuum decarburiza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com