Preparation method of foglight shell of passenger car

A technology for passenger cars and fog lamps, applied in vehicle components, transportation and packaging, optical signals, etc., can solve problems such as poor toughness, high cost, and heavy weight, and achieve poor low-temperature toughness, high-temperature hydrolysis, and reduced The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

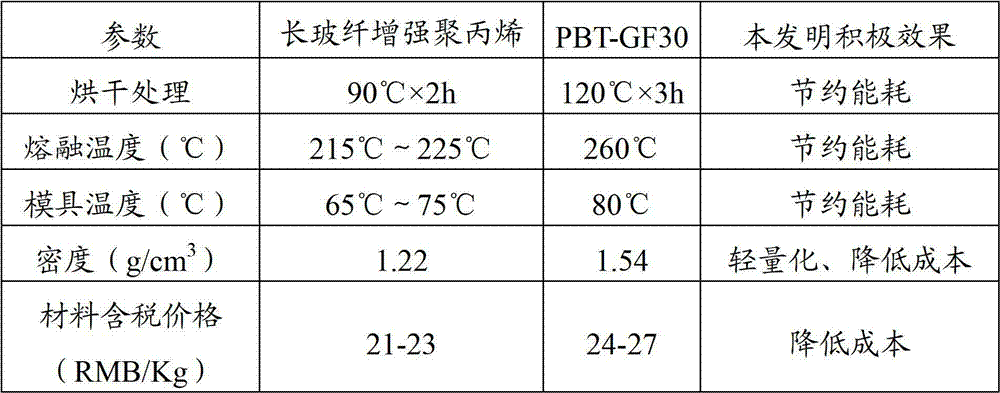

[0019] The preparation method of the passenger car fog lamp housing of the present invention adopts long glass fiber reinforced polypropylene material to prepare the fog lamp housing, comprising the following steps:

[0020] Step 1: Prepare the raw materials for the injection molded fog lamp housing, specifically:

[0021] Co-extrude after mixing modified polypropylene and glass fiber, so that the polypropylene polymer resin is evenly coated on the outer surface of glass fiber, and then co-extrude modified polypropylene and glass fiber to form long glass fiber reinforced polypropylene The material is cooled and cut to obtain pellets, the pellets are raw materials, the length of the pellets is 10-12mm, and the content of glass fiber is 40%;

[0022] The modified polypropylene is formed by stirring and mixing polypropylene materials, antioxidants, and ultraviolet absorbers, and then melting them, wherein the weight ratio of the modified polypropylene is 100 parts, and the weight...

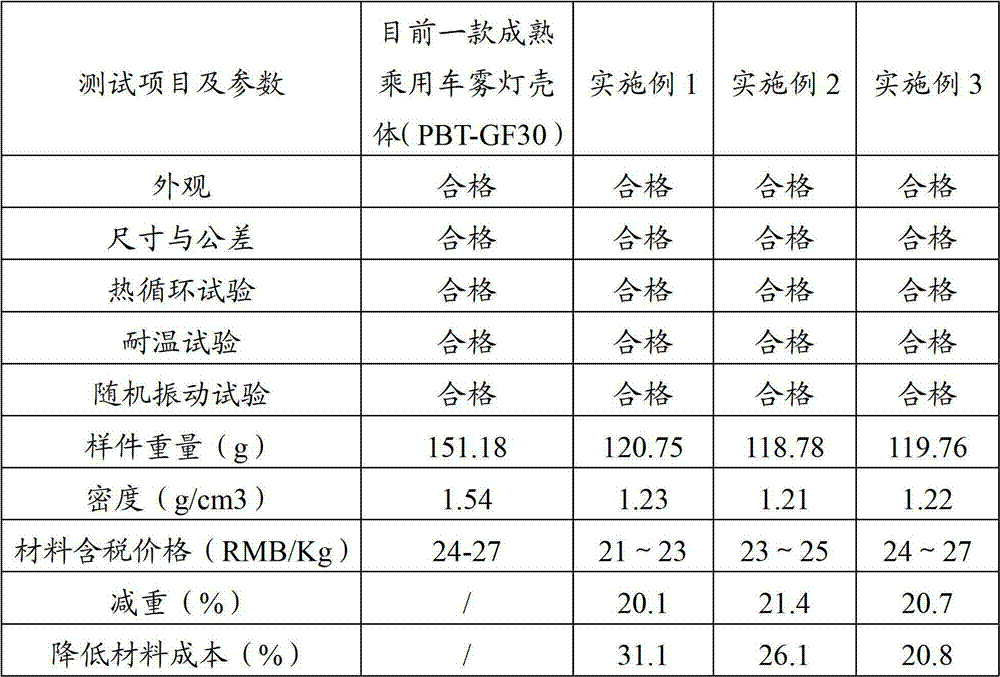

Embodiment 1

[0030] Example 1: Using long glass fiber reinforced polypropylene to prepare a fog lamp housing

[0031] Step 1: Co-extrude the modified polypropylene and glass fiber after mixing, so that the polypropylene polymer resin is uniformly coated on the outer surface of the glass fiber, and the modified polypropylene and glass fiber are mixed and co-extruded to form a long glass fiber The reinforced polypropylene material is cooled and cut to obtain pellets, the length of which is 12mm; wherein the content of glass fiber is 40%; the modified polypropylene is made of injection molding grade polypropylene and antioxidant, ultraviolet absorber The agent is melted and formed after stirring and mixing, wherein the weight ratio of the injection molding grade polypropylene is 100 parts, the weight ratio of the antioxidant 1010 is 0.3 parts, and the weight ratio of the ultraviolet absorber UV531 is 0.5 parts;

[0032] Step 2: drying the pellets, the drying temperature is 90°C, and the dryin...

Embodiment 2

[0035] Example 2: Using long glass fiber reinforced polypropylene to prepare a fog lamp housing:

[0036] Step 1: Co-extrude the modified polypropylene and glass fiber after mixing, so that the polypropylene polymer resin is uniformly coated on the outer surface of the glass fiber, and the modified polypropylene and glass fiber are mixed and co-extruded to form a long glass fiber The reinforced polypropylene material is cooled and cut to obtain pellets, the length of which is 12mm; wherein the content of glass fiber is 40%; the modified polypropylene is made of injection molding grade polypropylene and antioxidant, ultraviolet absorber The agent is melted and formed after stirring and mixing, wherein the weight ratio of the injection molding grade polypropylene is 100 parts, the weight ratio of the antioxidant 1010 is 1.2 parts, and the weight ratio of the ultraviolet absorber UV531 is 0.8 parts;

[0037] Step 2: drying the pellets, the drying temperature is 90°C, and the dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com