Totally enclosed environment-friendly type garbage vertical briquetting machine

An environmentally friendly and fully enclosed technology, applied in presses, manufacturing tools, etc., can solve the problems that sewage cannot be collected in a concealed manner, easily causes bacterial growth, and serious pollution, and achieves complete functions, low production costs, and reasonable structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

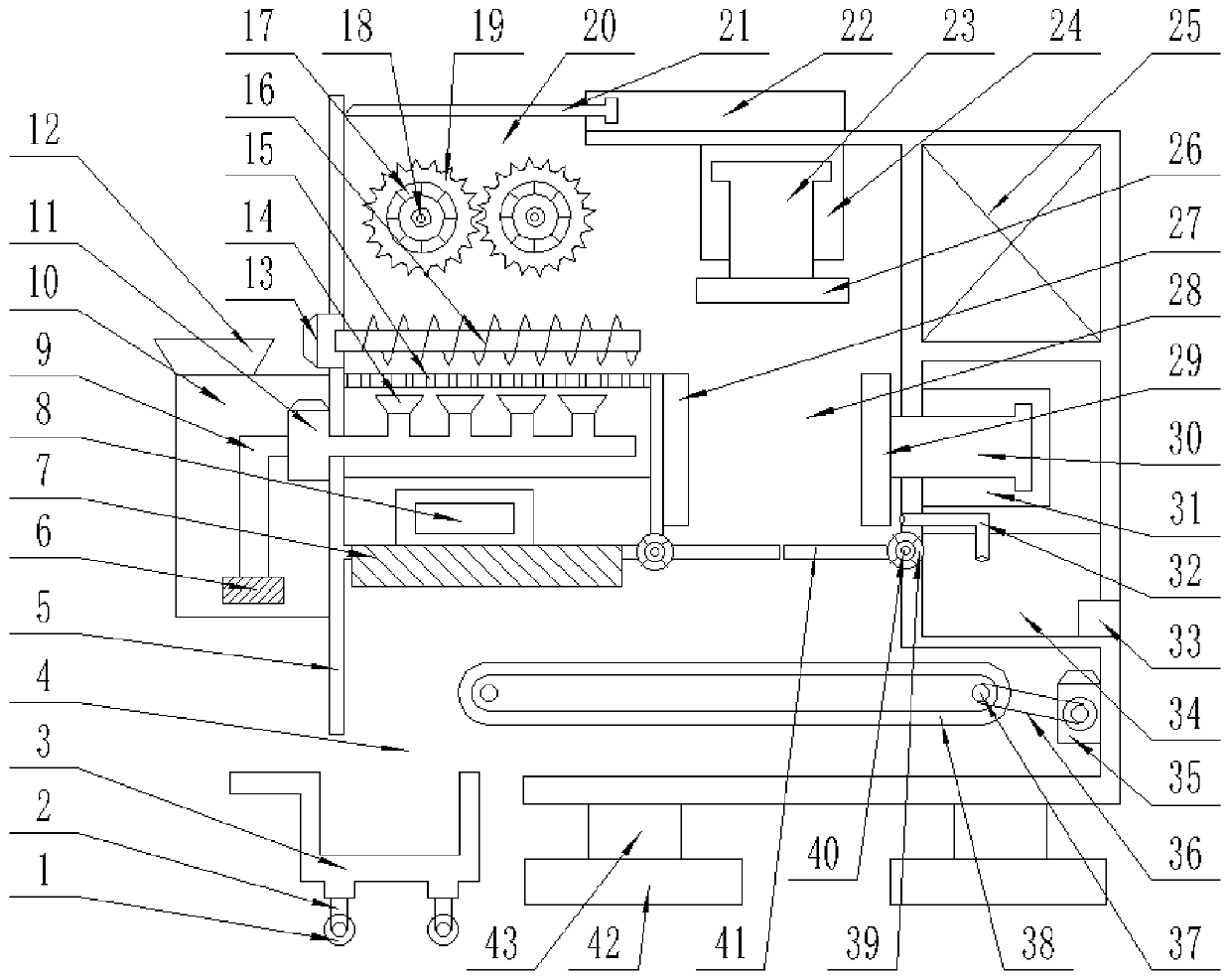

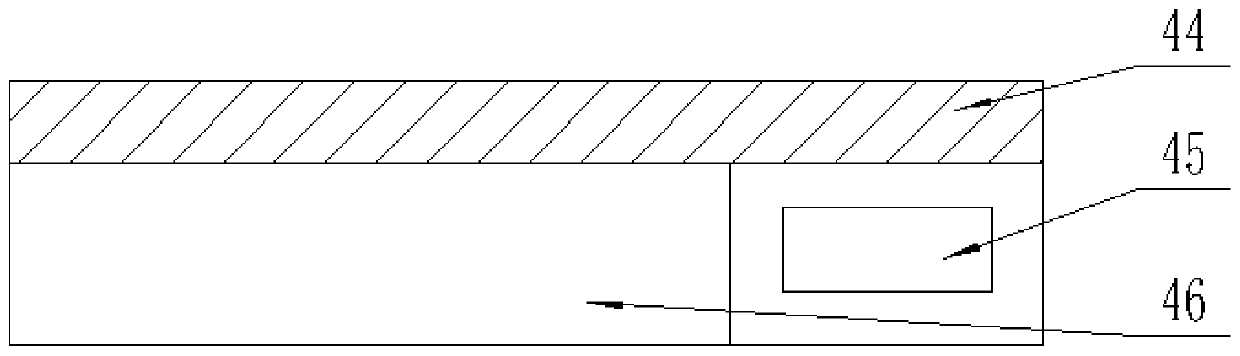

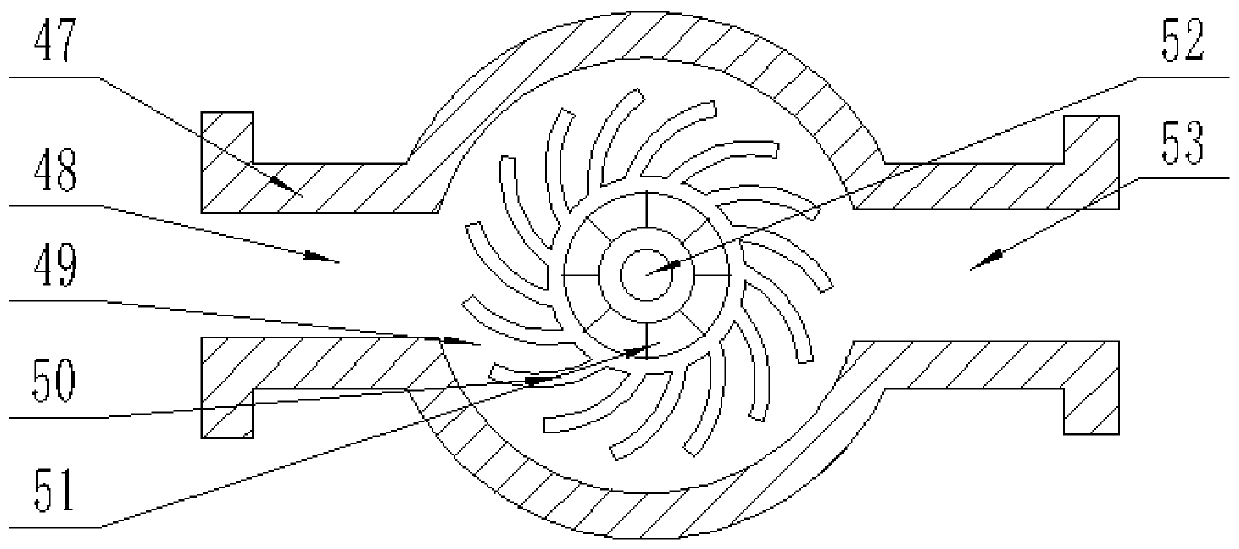

[0023] Such as figure 1As shown, the specific embodiment of the present invention adopts the following technical solutions: a fully enclosed environment-friendly garbage vertical briquetting machine, including universal wheel 1, universal wheel connecting rod 2, cart 3, discharge port 4, device housing 5 , filter tip 6, first heating wire 7, first electric heater 8, pipeline 9, water tank 10, water pump 11, water inlet 12, first motor 13, atomizing nozzle 14, filter screen 15, screw transmission rod 16, second Motor 17, load bearing shaft 18, crushing wheel 19, feed port 20, pneumatic door 21, cylinder 22, first hydraulic connecting rod 23, first hydraulic cylinder 24, dehumidification exhaust fan 25, first high temperature platen 26, second High temperature platen 27, extrusion chamber 28, third high temperature platen 29, second hydraulic connecting rod 30, second hydraulic cylinder 31, sewage pipe 32, sewage outlet 33, sewage pool 34, third motor 35, belt 36, transmission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com