Bracelet type wearing equipment and forming mould, manufacturing system and processing method of equipment

A technology for wearable devices and forming molds, applied in the field of wearable devices and their forming molds, can solve problems such as difficult mass production and no production process, and achieve the effect of simplifying the forming process and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

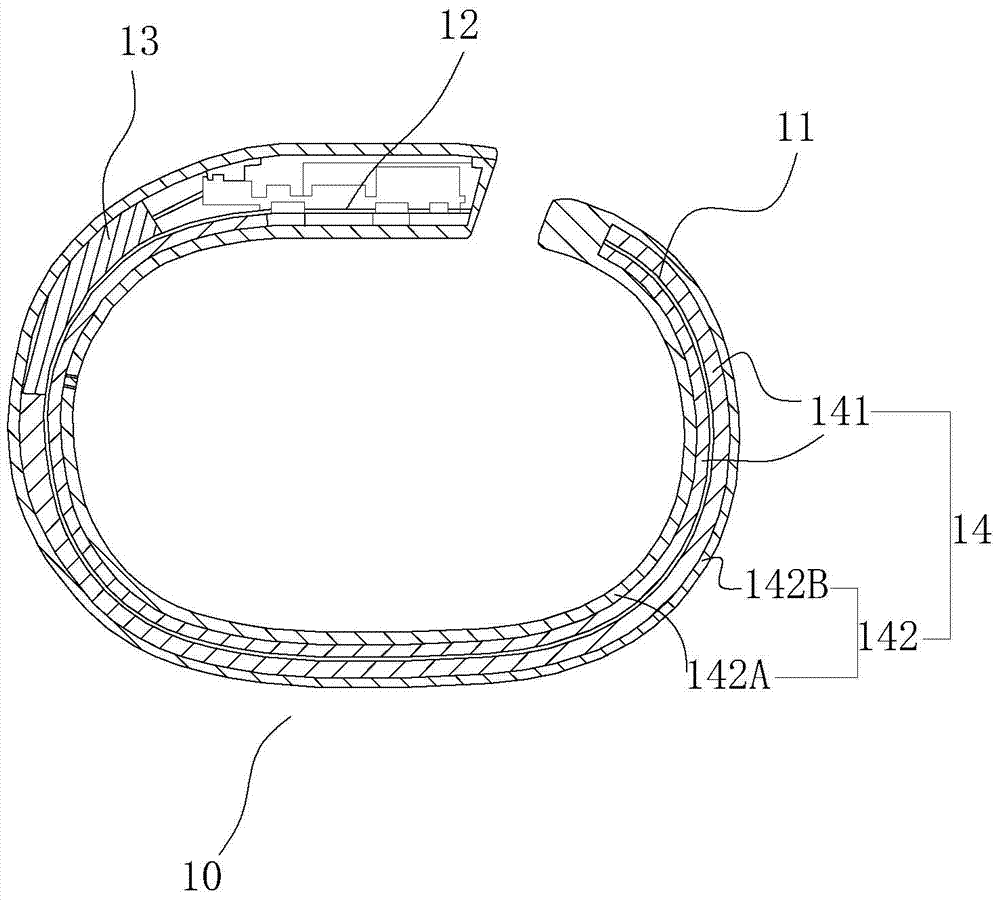

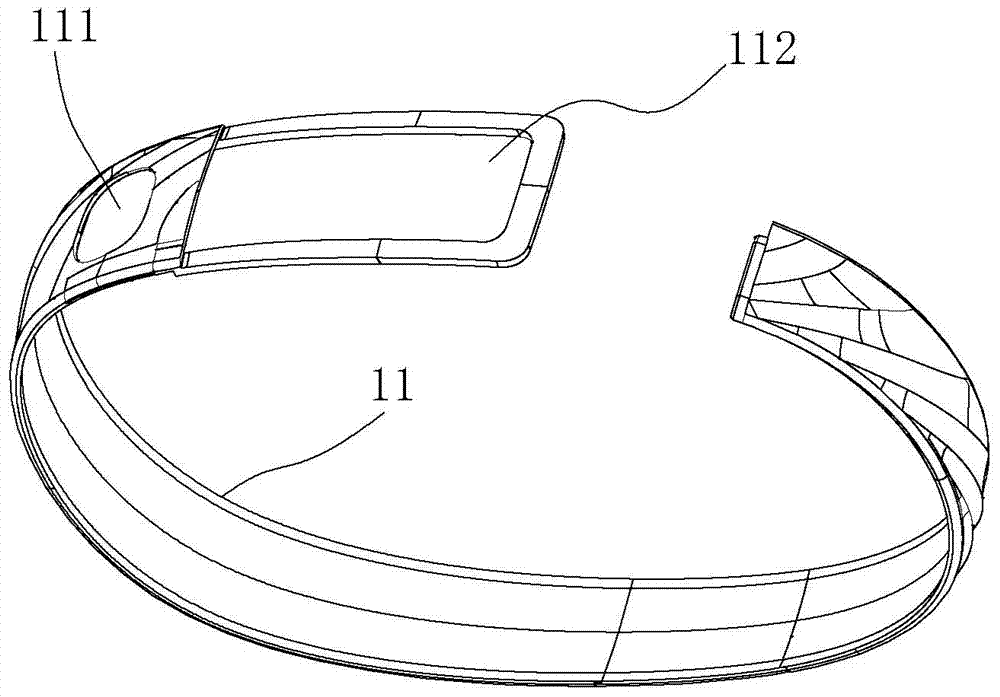

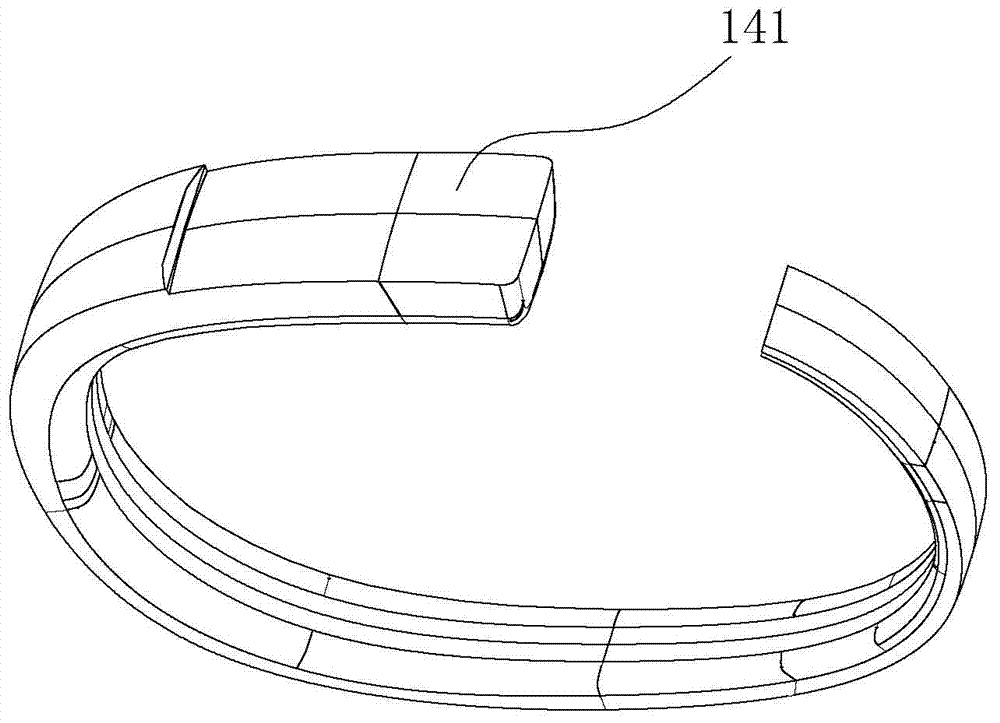

[0057] Figure 1 to Figure 3A The bracelet-type wearable device 10 of the present invention includes a wrist-shaped shrapnel 11 with an opening groove (also called a wristband opening) (there are button empty grooves 111 and PCB board grooves 112 on it), and are fixed on the wrist-like shrapnel. 11, the PCB board 12 on the outside of one end, the battery 13 fixed on the outside of the wrist-shaped shrapnel 11, and the housing 14 positioned at the outer periphery of the wrist-like shrapnel 11 and the battery 13; the housing 14 includes a hard inner shell 141 and is arranged in a hard inner A soft shell 142 on the periphery of the shell 141; an MCU chip electrically connected to the battery 13 is provided on the PCB 12 (not shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com