High strength toughness aluminum alloy and preparing method thereof

An aluminum alloy, high-strength technology, applied in the field of aluminum alloy materials, can solve the problems of poor mechanical properties and low toughness, and achieve the effects of convenient operation, high toughness and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the high-strength and tough aluminum alloy comprises the following steps:

[0035] (a) Prepare raw materials and ingredients according to the designed alloy composition, the raw materials are pure aluminum, pure magnesium and Al-20% Si or Al-22% Si, Al-15% Mn or Al-10% Mn, Al-10% Sr master alloy and Al-15%Ce master alloy;

[0036] (b) Melting the alloy raw materials, putting the prepared raw materials into a melting furnace for melting, using a Fe-free graphite material crucible or silicon carbide material crucible or a mixed material crucible for melting, and the melting temperature is 720°C to 740°C. After the raw material smelting is completed, adjust the temperature of the melt to 700°C to 720°C, and then use the method of rotating nitrogen blowing to carry out refining treatment of degassing and impurity removal on the alloy melt for 10 minutes to 15 minutes to obtain a high-quality melt;

[0037] (c) Die-casting, pour the alloy melt into...

Embodiment 1 to Embodiment 5

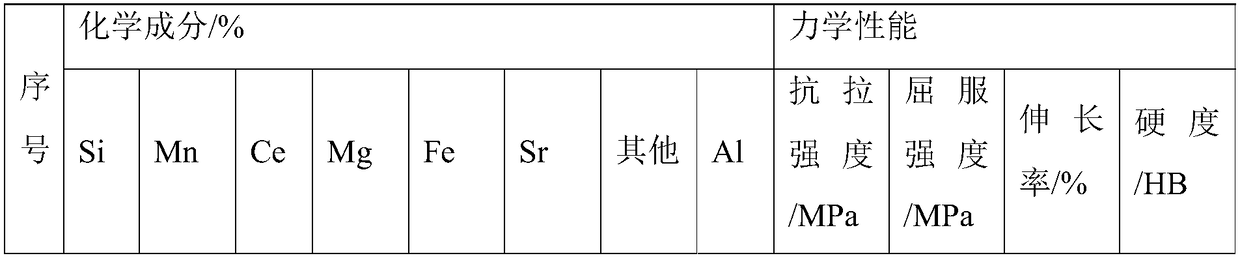

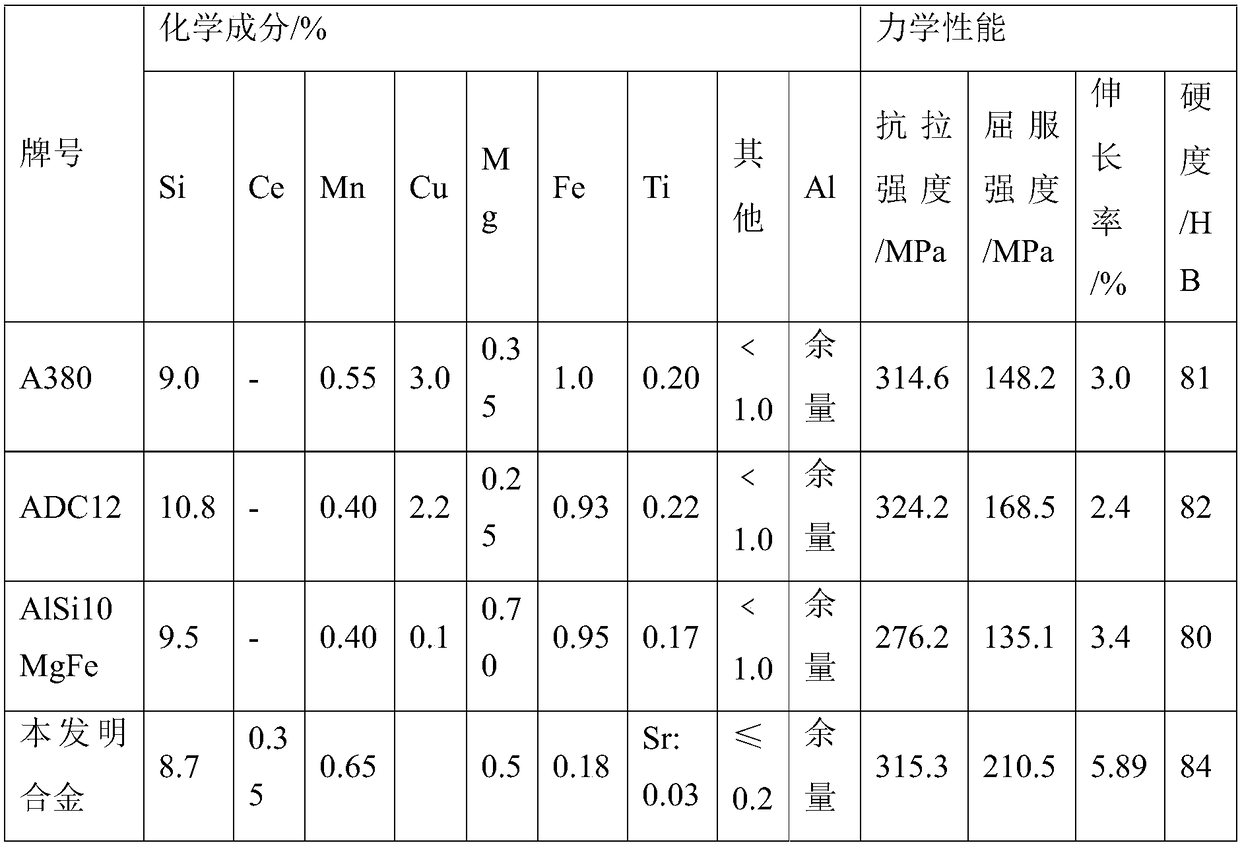

[0046] The Al-Si-Mn-Ce die-casting aluminum alloy materials of Examples 1-5 were manufactured according to the content formula of each component shown in Table 1. The properties of the prepared aluminum alloys are shown in Table 1.

[0047] The preparation method of the high-strength and tough aluminum alloy comprises the steps of:

[0048] Put the raw materials in Table 1 into a crucible melting furnace that does not contain Fe for melting, the melting temperature is 720°C-740°C; after the raw material melting is completed, adjust the melt temperature to 700°C-720°C, and then use rotary nitrogen blowing The alloy melt is subjected to refining treatment of degassing and impurity removal by means of refining method for 10 minutes to 15 minutes to obtain aluminum alloy melt. The alloy melt is poured into the pressure chamber of the die-casting machine, and the parts are formed by vacuum die-casting immediately, and the pouring temperature is controlled at 660°C to 680°C. Among ...

Embodiment 6 to Embodiment 11

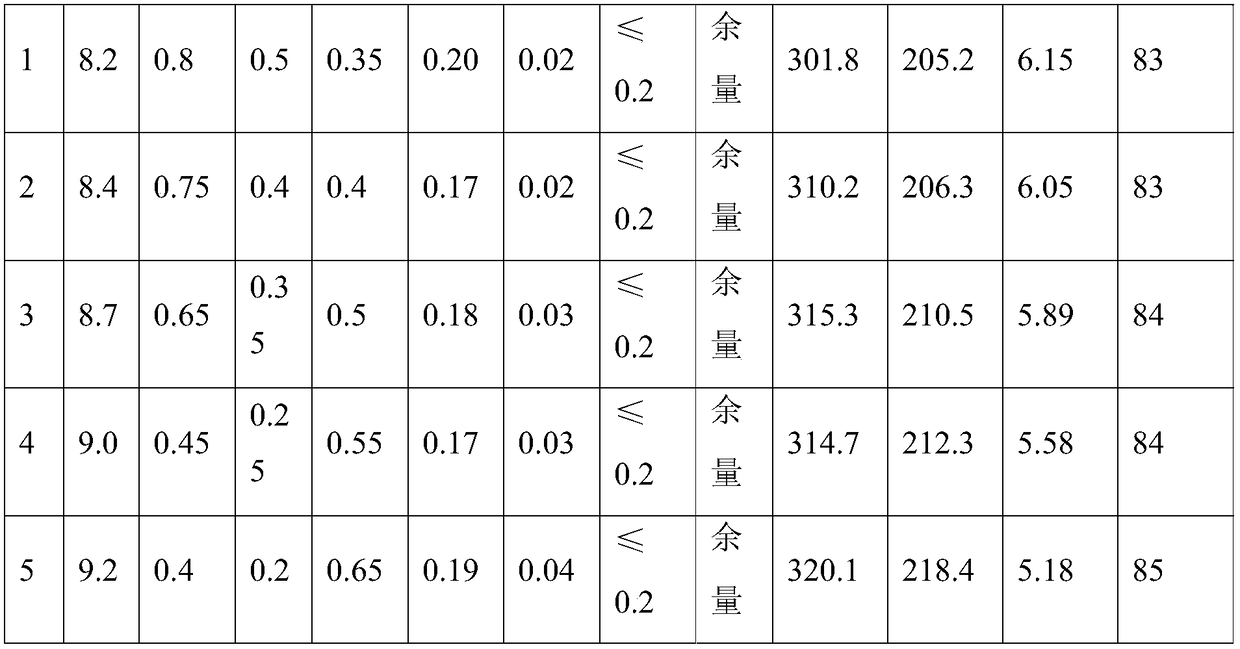

[0057] First, for the Si element, according to the smelting process and die-casting process parameters of Examples 1-5, the mechanical properties of aluminum alloys with different Si contents were measured for flat samples with a wall thickness of 4 mm, as shown in Table 3. The results show that when the Si content is lower than 8.2%, the strength of the alloy is low, the yield strength is lower than 185MPa, and the elongation is higher; when the Si content is higher than 9.2%, the strength of the material is increased but the toughness is poor , and its elongation is lower than 5%, so the optimum Si content is controlled at 8.2% to 9.2%.

[0058] Table 3 Material composition and mechanical properties of die-casting aluminum alloys with different Si contents in Examples 6-11

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com