Case-hardening steel and case-hardened steel member

a technology of case-hardening steel and hardening steel, which is applied in the direction of solid-state diffusion coating, coating, metallic material coating process, etc., can solve the problems of not considering the prevention of crack initiation, no description of cold forging, and no description of a technique for improving temper softening resistance, etc., to achieve excellent cold forging, excellent temper softening resistance, and high hardness of a carburized layer. excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

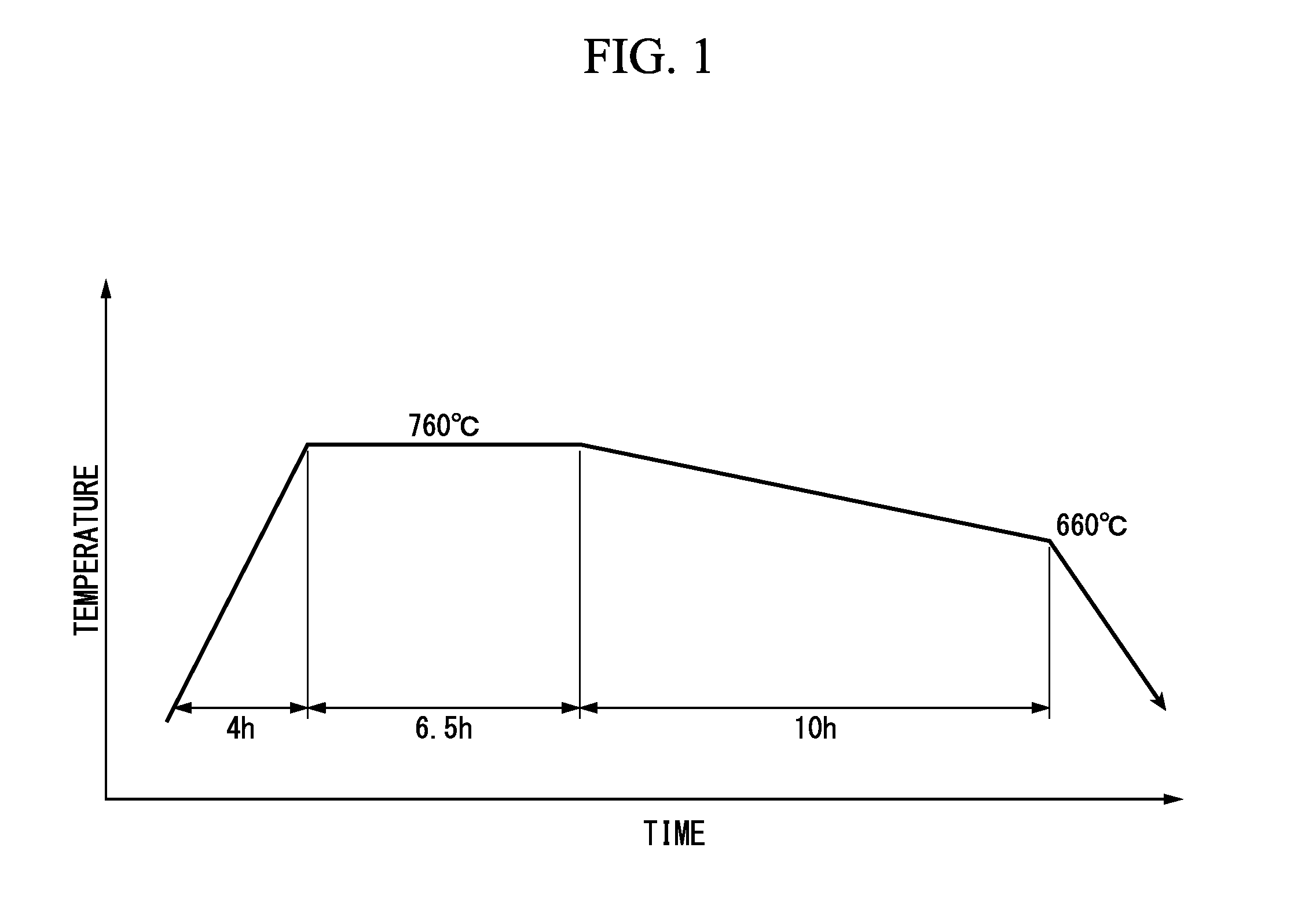

[0144]Hereinafter, the present invention will be further described using Examples. Converter molten steels having the compositions (chemical composition) shown in Tables 1-1 and 1-2 were subjected to RH vacuum degassing under the conditions shown in Table 2 and subsequently subjected to continuous casting under the conditions shown in Table 3, and then subjected to soaking as required. Through blooming, rectangular rolled steels (billets), having a square-shaped cross section whose length of one side is 162 mm were obtained. The balance in Tables 1-1 and 1-2 includes iron and impurities and the blank indicates that the component is intentionally not added.

TABLE 1-1STEELCHEMICAL COMPOSITION (MASS %)No.CLASSIFICATIONCSiMnPSCrMoCuNi1EXAMPLE0.180.500.440.0160.0151.450.352EXAMPLE0.210.800.540.0150.0161.210.160.023EXAMPLE0.200.700.600.0050.0011.100.024EXAMPLE0.121.500.200.0110.0151.960.025EXAMPLE0.220.450.700.0011.260.161.506EXAMPLE0.210.400.750.0080.0141.300.047EXAMPLE0.200.700.600.0300....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com