Process utilizing upper flat and lower V-shaped anvil to forge stepped shafts

A process method and technology for stepped shafts, which are applied to the field of forging stepped shafts with upper and lower V anvils, can solve the problems of poor forging permeability, prolonged forging time, influence of forging temperature, etc., and achieve good internal stress state of billet, good stress state and good quality. The effect of forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

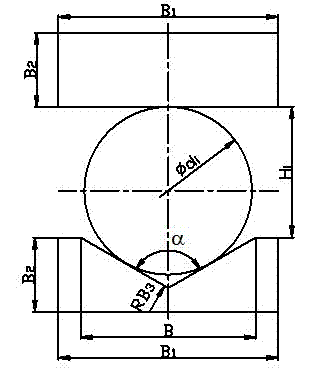

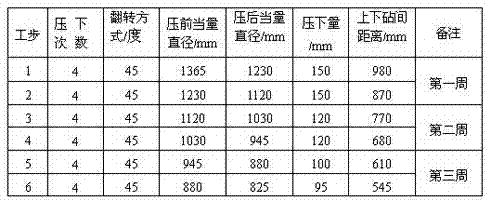

[0026] Φ1365mm backup roll billet (material 70Cr3Mo) has a roll body size of Φ1365mm, large steps on both sides of the roll body are Φ815mm, and small steps are Φ560mm. The entire forging process is completed on a 5000t hydraulic press, which is divided into forged roll body and steps on both sides of the forged roll body Two stages; after the forging of the roller body is completed, the forging blank is Φ1365mm, and the forging blank is sent back to the heating furnace for heating. At the same time, the hydraulic press replaces the anvil, the upper anvil is replaced with a flat anvil with an axial width of 700mm, and the lower anvil is replaced with an upper axial anvil width. 700mm V-shaped anvil: V-shaped angle 120°, opening width 1180mm, such as figure 1 As shown, when the forging billet is heated to 1250±10°, step forging is carried out. First, the size of the steps on both sides of the roll body is extended to Φ815mm, and then the two ends are extended to a small step siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com