Production method of low-temperature high-strength high-toughness steel for lifting rings

A production method, high-strength and high-toughness technology, applied in the field of suspension ring production, can solve the problems that affect the safety and reliability of drilling rig equipment, it is difficult to meet the safety factor of drilling rig equipment, and the design of suspension ring material components is unreasonable, etc., to improve the service life, Effect of improving internal structure and refining grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

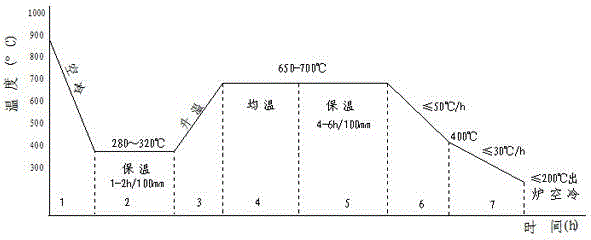

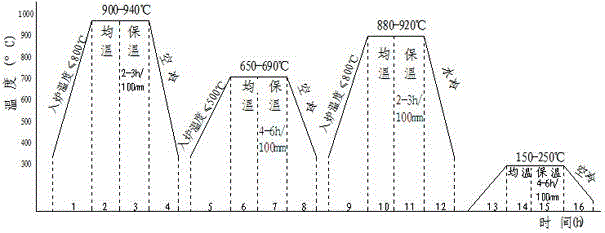

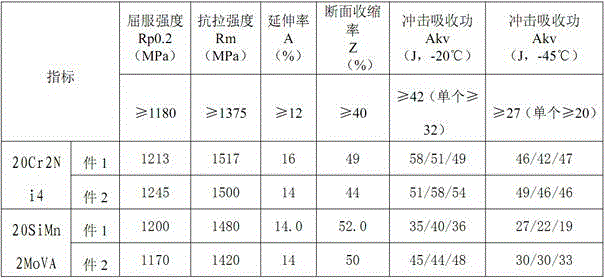

[0012] The invention discloses a production method of low-temperature, high-strength and high-toughness steel for suspension rings. The steel type of suspension rings is selected as 20Cr2Ni4, and it is formed through material selection-refining-electroslag-forging-forging and post-forging heat treatment.

[0013] After material selection, EAF+LF+VD refining method is adopted. The furnace charge is composed of scrap steel of grade two or above, pig iron, and returned steel material. After EAF oxidation, the steel is tapped, pre-deoxidized and partially alloyed in the ladle, and refined by LF argon blowing , White slag retention time ≥ 20 minutes, before degassing, adjust the composition according to the internal control composition, carry out VD vacuum degassing, at ≤ 0.5 Torr, the retention time ≥ 25 minutes, blow argon weak stirring time ≥ 12 minutes before tapping, and use it after tapping and calming Argon protection pouring, hot electroslag remelting after electrode billet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com