Method for producing aluminum-alloy shaped product, aluminum-alloy shaped product and production system

a technology of aluminum alloy and production system, which is applied in the direction of heat treatment apparatus, machines/engines, furniture, etc., can solve the problems of difficult to reduce internal defects, difficult to reduce the weight of the piston, and inability to examine the mechanical characteristics of high-temperature cast products, etc., to achieve excellent mechanical strength, reduce the thickness of the piston, and achieve the effect of easy production of aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0142]The present invention will be specifically described below by using examples. However, the present invention is not limited to these examples.

examples 1 to 16

[Manufacturing Conditions]

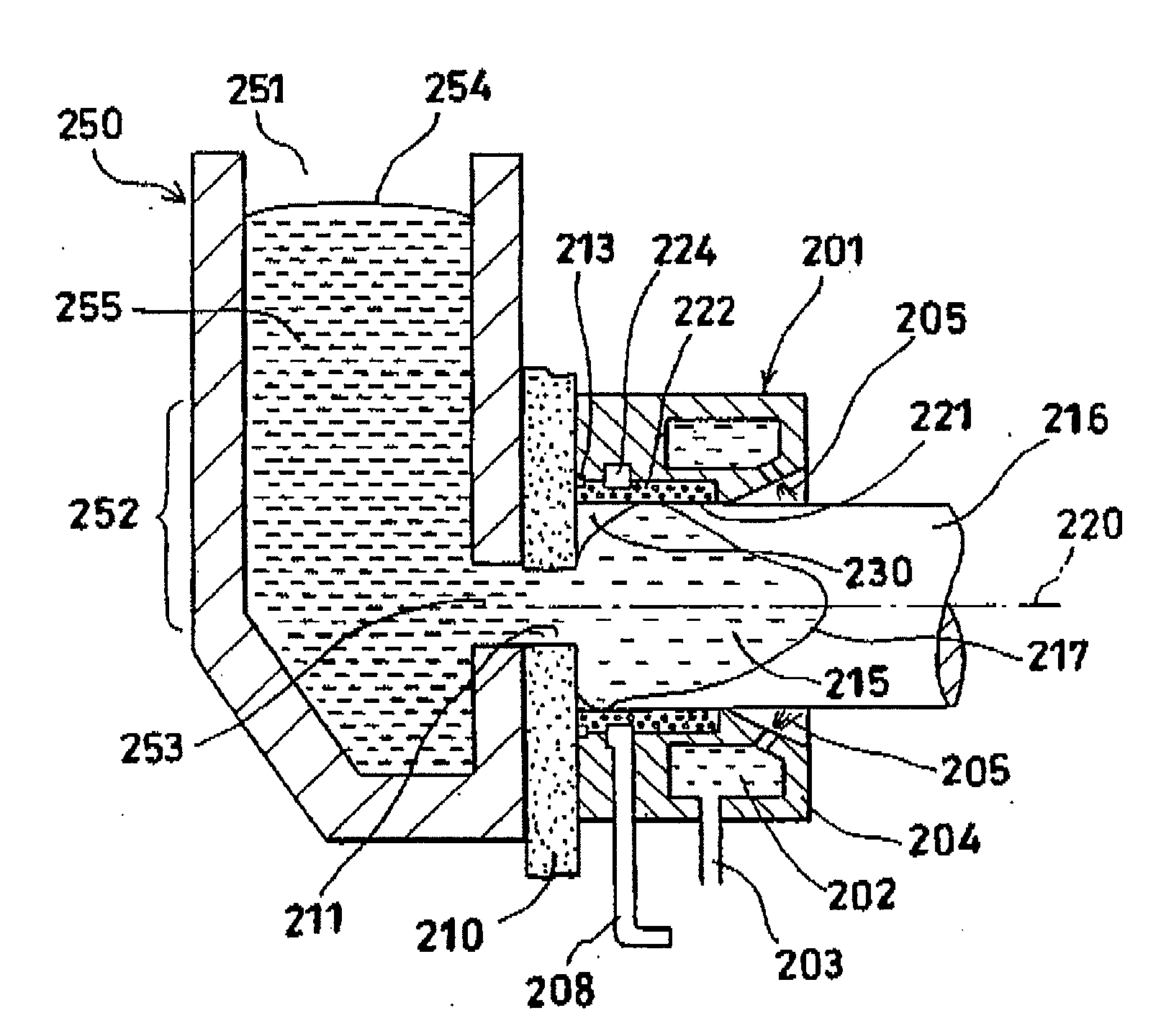

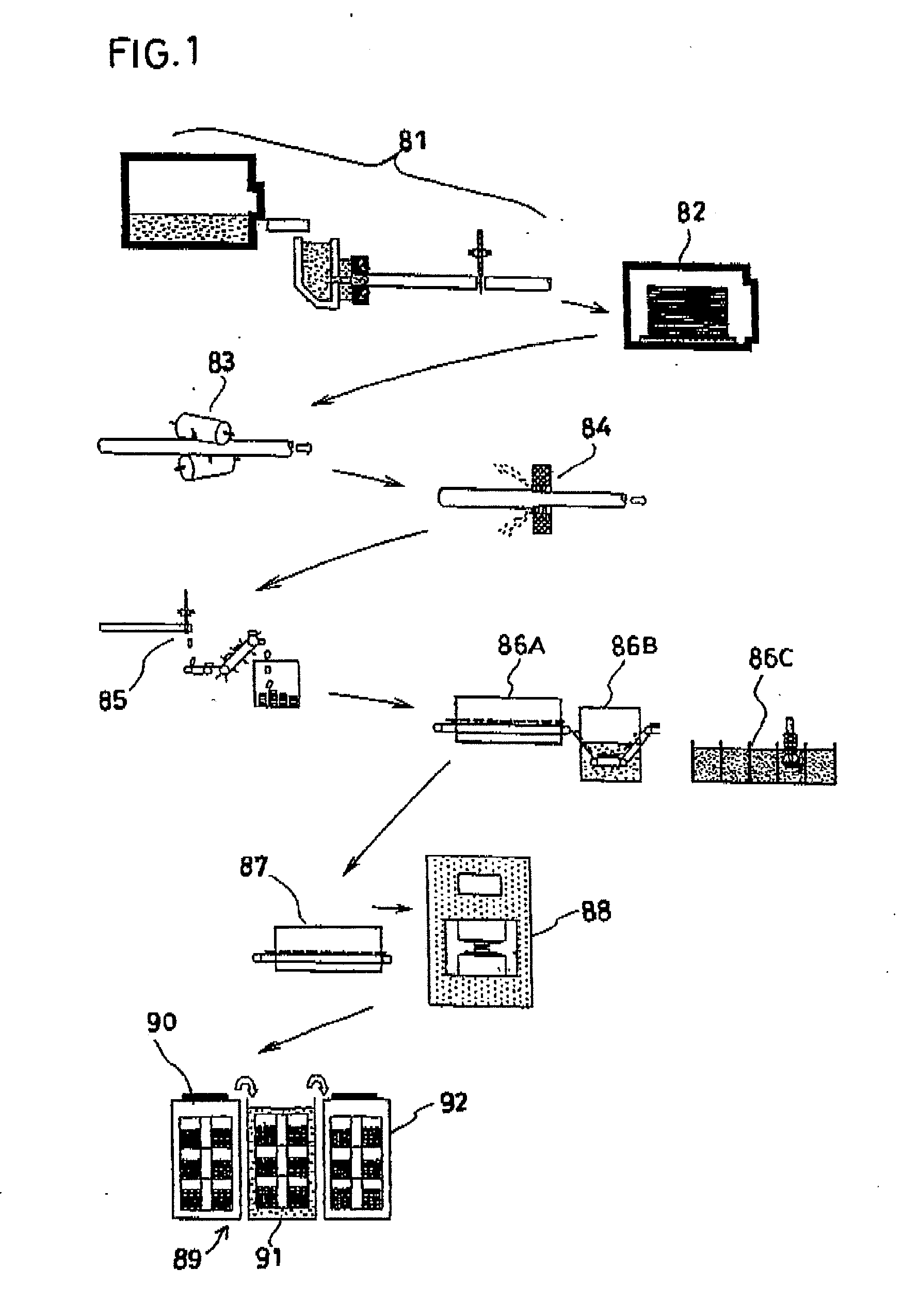

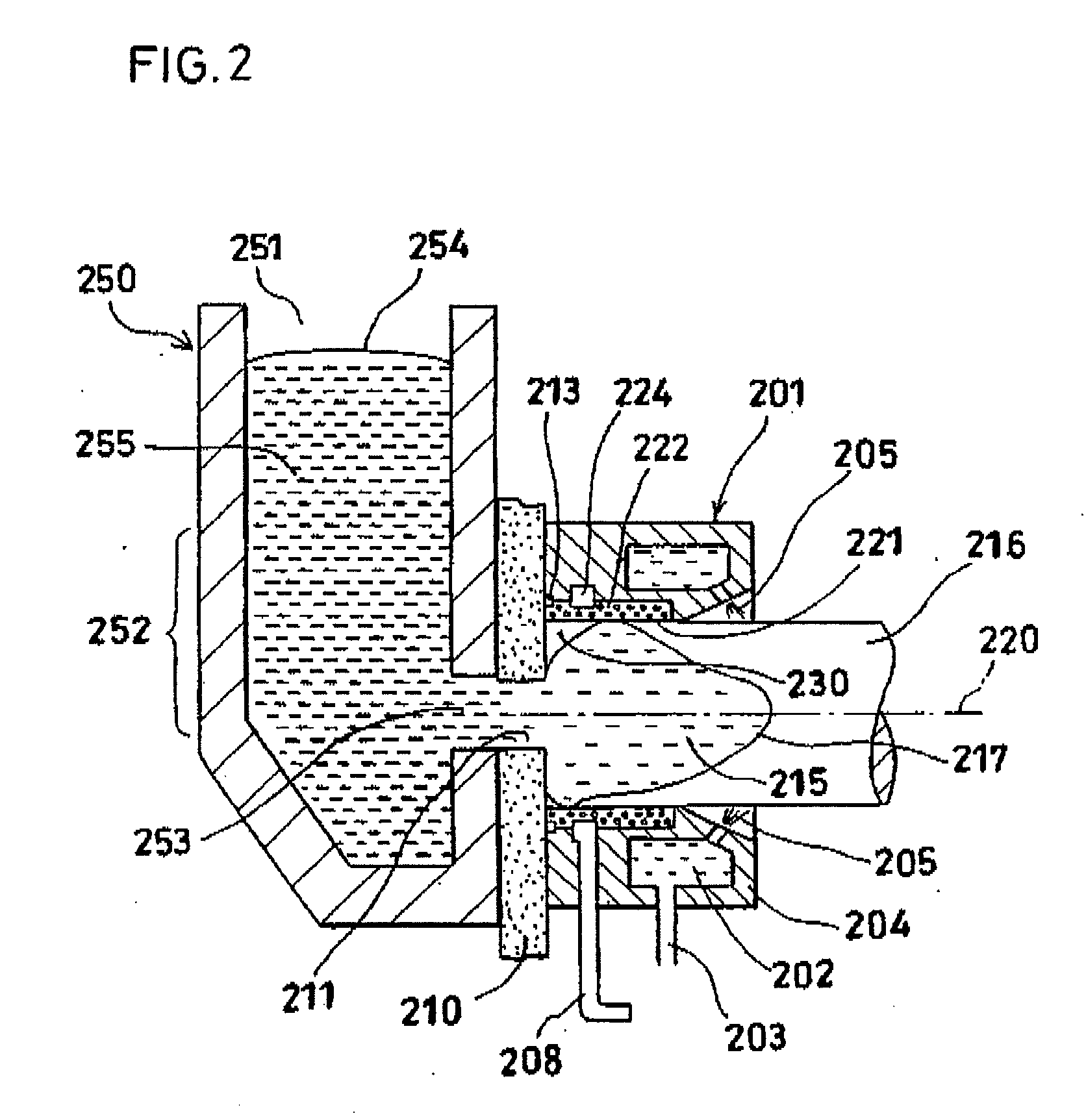

[0143]The aluminum-alloy shaped product of Examples 1 to 16 shown in Table 1 and Comparative Examples 1 to 10 shown in Table 2 were produced by a production system shown in FIG. 1.

TABLE 1TemperaturePercentPost-Fatigur Strength Stressof Homoge-reductionHeat(Unit: MPa)nizationduring theTreat-TemperatureTemperatureValueTreatmentcourse ofmentComposition of Aluminum-alloy (% by mass)ConditionConditionof(° C.)upsetting(T6, T5)SiFeCuMnMgNiTiPSr300° C.350° C.AAExample 137050%T610.50.252.7—0.953.8——0.01560455.64Example 237050%T610.50.252.7—0.953.8—0.015—59445.64Example 337050%T612.80.483.00.230.953.00.0750.018—59435.04Example 437050%T512.80.483.00.230.953.00.0750.018—62445.04Example 537050%T611.80.333.2—0.722.2—0.005—54394.38Example 637050%T612.80.253.8—0.951.8—0.018—53384.38Example 737050%T613.40.254.1—1.102.2—0.018—57434.99Example 837050%T613.40.614.10.321.212.2—0.010—58434.99Example 9not over 20050%T613.40.614.10.321.212.2—0.010—59444.99Example 1037050%T612.80.48...

examples 17 and 18

[Manufacturing Conditions]

[0162]Examples 17 and 18 and Comparative Examples 11 and 12, respectively, were produced under the composition and manufacturing conditions shown in Table 5 by the same method for production as Examples 1 to 16 and Comparative Examples 1 to 10.

[0163]Meanwhile, Comparative Example 13 was made of a powdery extruded-cast material, and was produced by the same method for production as Comparative Examples 11 and 12 except that Comparative Example 13 was not formed from a continuously cast round rod made of an aluminum-alloy and a homogenization treatment was not performed. All Examples 17 and 18 and Comparative Examples 11 to 13 were formed as the aluminum-alloy shaped product having the shape of a piston 1 that had a diameter of 80 mm and a top surface 10 having a thickness of 8 mm as shown in FIGS. 7A to 7C.

[Evaluation of Fatigue Strength]

[0164]The fatigue strength of each of Examples 17 and 18 and Comparative Examples 11 to 13 was evaluated by the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com