Die forging shaping technology specially used for manufacturing petroleum drilling machine elevator movable wing plates

A technology of movable wings and forgings, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of high energy consumption, low machining efficiency, low utilization rate of raw materials, etc., and achieve material cost saving, Good die forging effect and novel structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: with reference to attached Figure 1-1~2-4 . A die forging process for forming the movable wing plate of the elevator of the oil drilling rig, the preparation work before die forging:

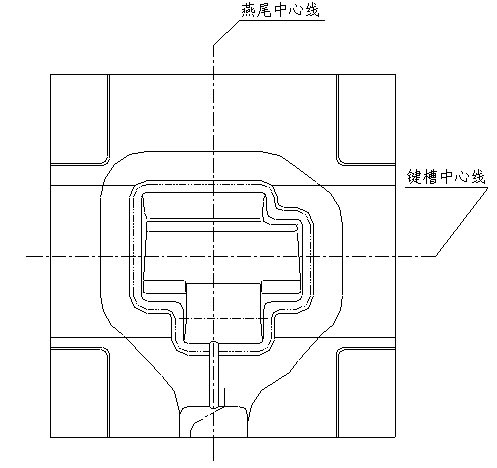

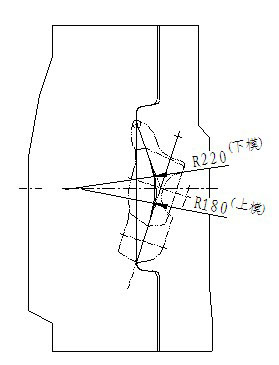

[0030] ⑴ Carry out technological corrections to the forging structure and draw a reasonable die forging diagram: by adjusting the angle of the parting surface, eliminate the drop of the parting surface, so as to achieve the purpose of balancing the horizontal displacement force generated during the die forging process, and through The forgings were corrected in technology, so that the forgings could be released from the mold smoothly;

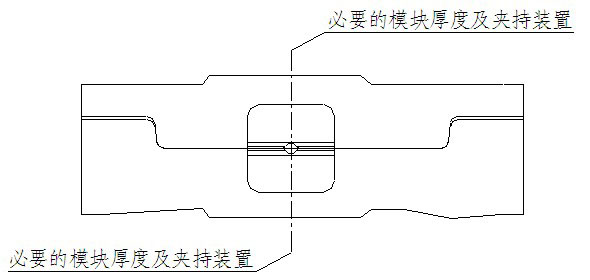

[0031] (2) Hammer forging die: The two ends of the parting surface of the forging die are on the same plane, and the parting transition surface formed is arc-shaped, and the cavity is divided into upper and lower parts with roughly similar volumes to ensure that the metal is deformed by hammering. Reasonable distribution and flow in the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com