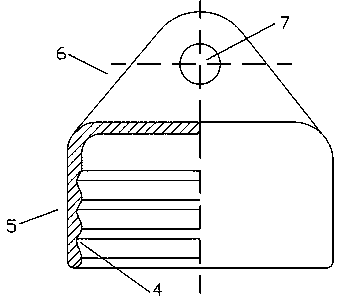

Machining technology for electrified railway overhead line system metal die forging porcelain insulator lower steel cap

A technology for electrified railways and porcelain insulators, applied in circuits, insulators, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention relates to a processing technology for the lower steel cap of the metal forged porcelain insulator of the electrified railway catenary, which is processed according to the following steps in sequence:

[0028] 1) Cut the Q235B bar material into a blank with a size of Φ70mm×125mm.

[0029] The preferred cutting method is: place the Q235B bars on the longitudinally extending non-powered horizontal conveying roller line, the front of the roller line is provided with a rear clamping mechanism and a front clamping mechanism for the bars to pass through, and the rear clamping mechanism and the front The clamping mechanism can switch between clamping and loosening the bar, and a direct-acting travel switch is provided in front of the front clamping mechanism. The saw blade of the electric circular saw is located between the front clamping mechanism and the direct-acting travel switch. The longitudinal distance between the saw blade and the direct-acting travel sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com