Integrated mixed driving type double-cylinder serial pressurizing oil press

A hybrid drive and hydraulic press technology, applied in forging presses, forging presses, and forging press driving devices, etc., can solve the problems of large working noise, large space occupation, slow response speed, etc., and achieve the effect of reduced load and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

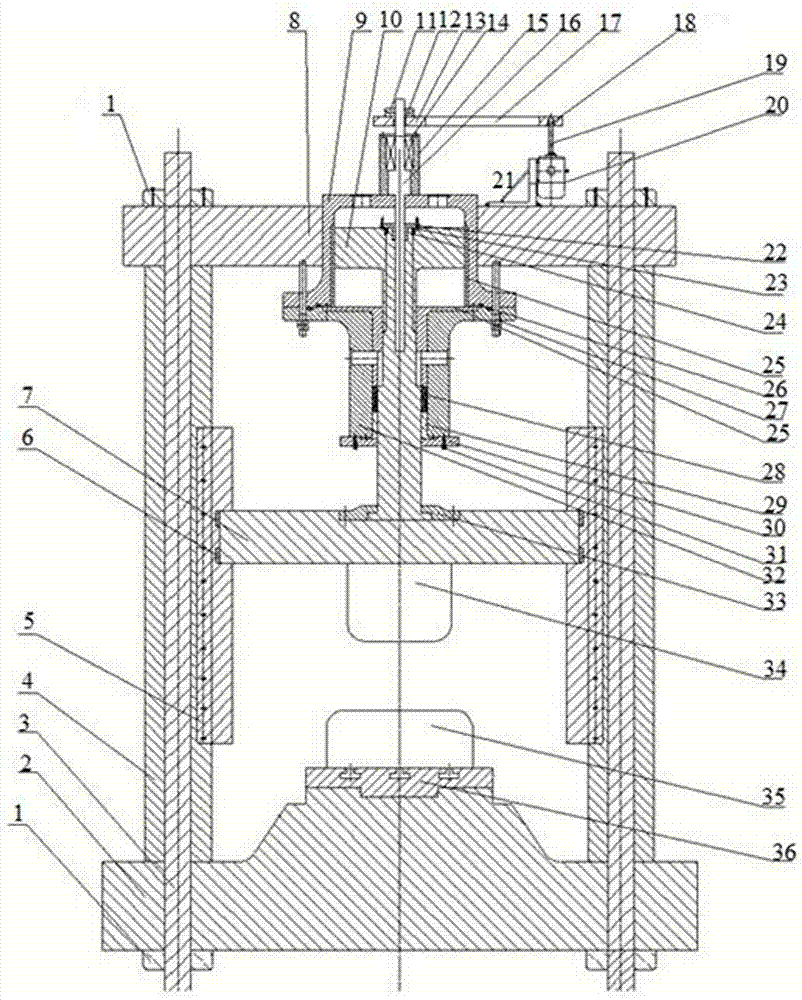

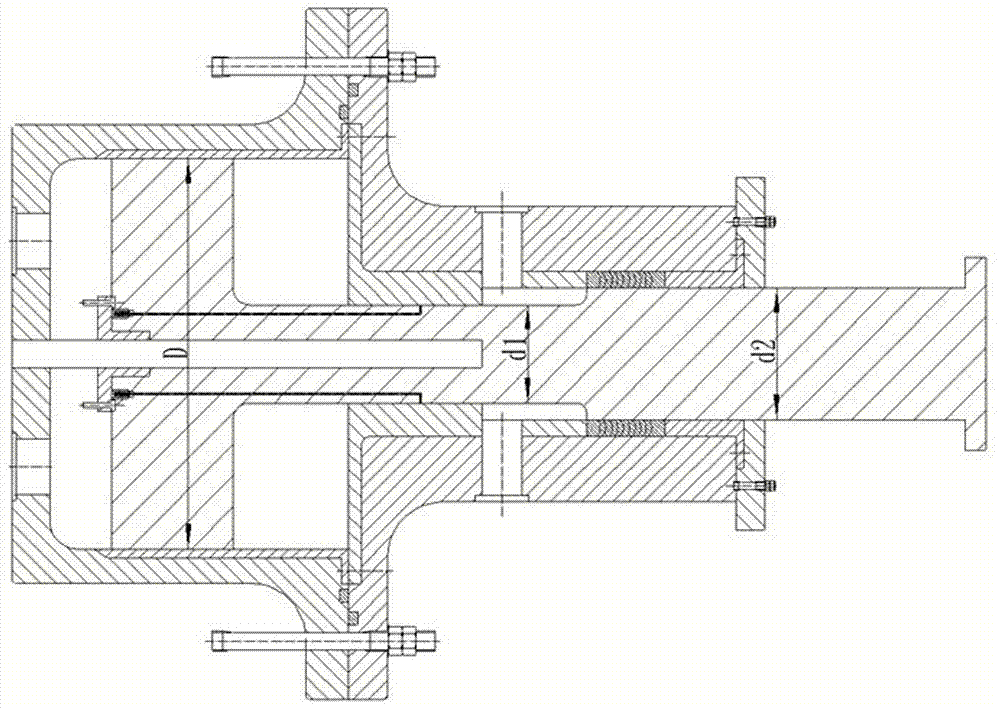

[0016] Such as Figure 1-2 As shown, an integrated hybrid drive type double-cylinder series booster hydraulic press, the hydraulic press is a prestressed frame type hydraulic press, including the upper beam 8 and the lower beam 2, the two ends of the upper beam 8 and the lower beam 2 are supported by the column 4, and the column 4 There is a tie rod 3 running through the upper beam 8 and the lower beam 2 inside, and the two ends of the tie rod 3 are fixed by super nuts 1; among them, the middle part of the column 4 is provided with a fixed plate 5 in the axial direction, and the fixed plate 5 is provided with a slide plate 6 in the vertical direction, and a slide plate 6 The movable crossbeam 7 is fixed on the top, the lower surface of the movable crossbeam 7 is fixedly connected to the upper anvil 34, the lower anvil 35 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com