Forging die capable of achieving automatic discharging

An automatic unloading and moving mold technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problem that the forging mold cannot be unloaded automatically, so as to improve the demoulding efficiency and Forging efficiency, simple structure, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

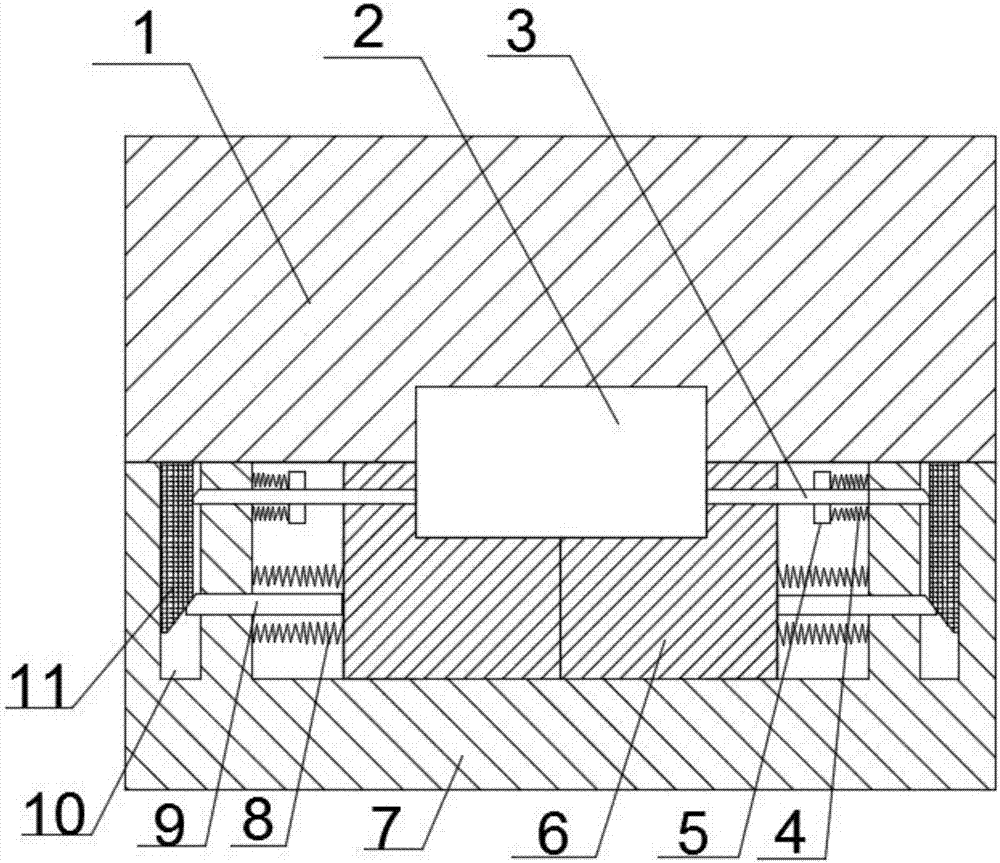

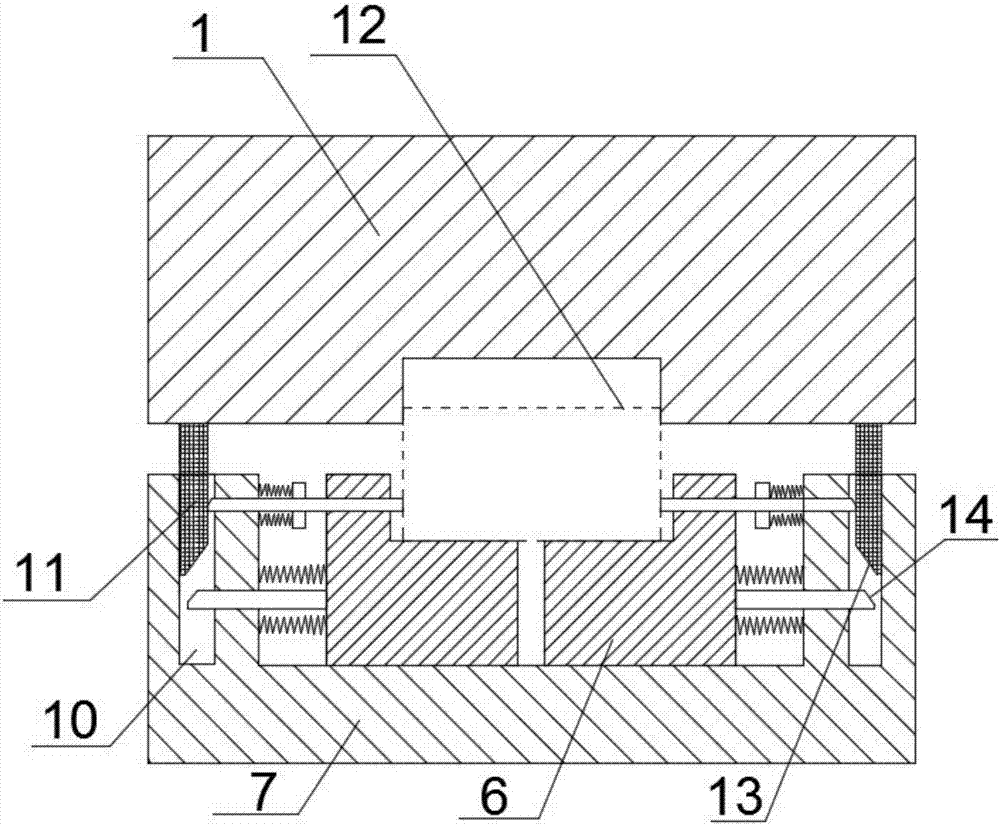

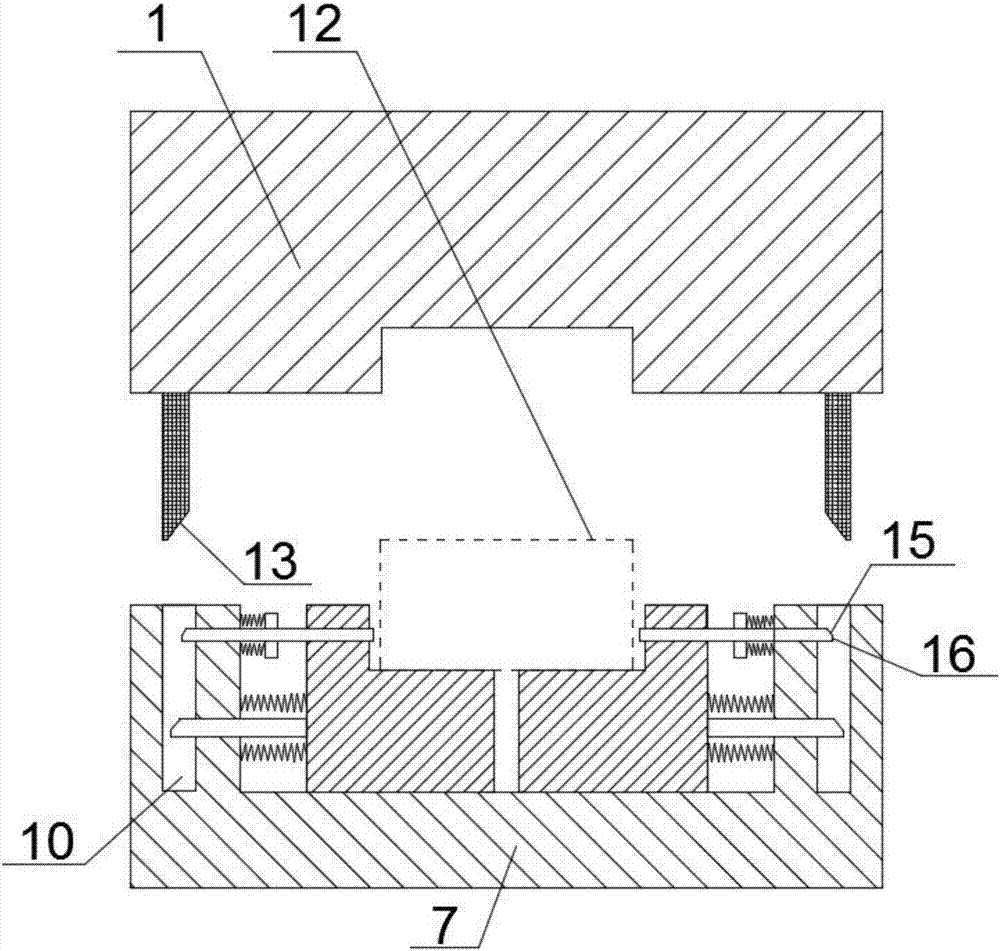

Embodiment 1

[0021] A forging mold capable of automatic unloading, comprising a movable mold 7 and a fixed mold 1, the upper end of the movable mold 7 and the lower end of the fixed mold 1 are provided with relative concave molds, and the concave mold on the movable mold 7 is There are two moving blocks 6, the moving blocks 6 are L-shaped and oppositely arranged, and form a cavity 2 matching the shape of the forging with the fixed die 1; Rod 11, the two ends of the movable mold 7 are provided with a groove 10 cooperating with the pressure rod 11, and the free end of the pressure rod 11 is provided with a first slope 13; the two ends of the movable mold 7 are provided with a first unloading mechanism And the second unloading mechanism, the first unloading mechanism includes a horizontal push rod 9 fixedly connected with the moving block 6 and the first elastic member 8 connecting the moving block 6 and the inner wall of the die, and the free end of the push rod 9 stretches into the groove 1...

Embodiment 2

[0024] Based on Embodiment 1, a stop surface 16 is provided at the lower end of the third slope 15 , and the stop surface 16 is in contact with the outer wall of the pressing rod 11 . By setting the stop surface 16 , it is beneficial to keep the fixing rod 3 stable during the movement of the pressing rod 11 relative to the groove 10 .

Embodiment 3

[0026] Based on Embodiment 1, there are gaps between the push rod 9 and the inner wall of the groove 10 and between the fixed rod 3 and the inner wall of the groove 10 for the front end of the pressure rod 11 to pass through, which can effectively prevent the push rod 9 and the fixed rod 3 from reaching the groove 10. The contact of the inner walls affects the cooperation of the first slope 13 , the second slope 14 and the third slope 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com