Near-net forming forging method of integrated bottom head of nuclear reactor pressure vessel

A technology of pressure vessels and nuclear reactors, applied in applications, manufacturing tools, forging/pressing/hammer devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The near-net-shape forging method of the nuclear reactor pressure vessel integrated bottom head of the present invention comprises the following steps:

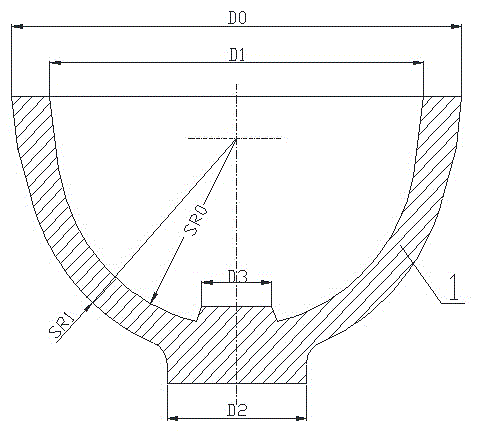

[0034] Step one, such as figure 1 As shown, determine the characteristic size parameters of the overall bottom head 1, the outer diameter of the upper opening D0, the inner diameter of the upper opening D1, the outer boss diameter of the lower mouth D2, the inner boss diameter of the lower mouth D3, the inner spherical radius SR0, and the outer spherical radius SR1;

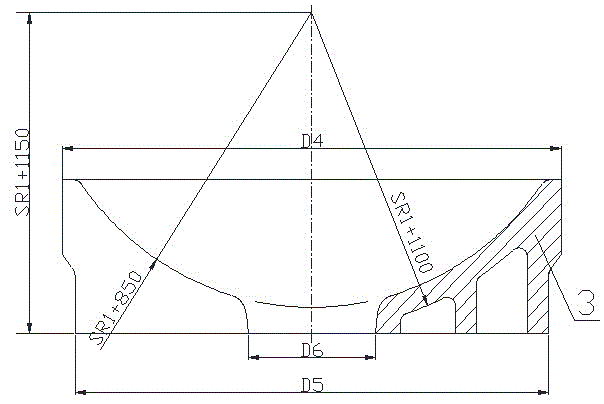

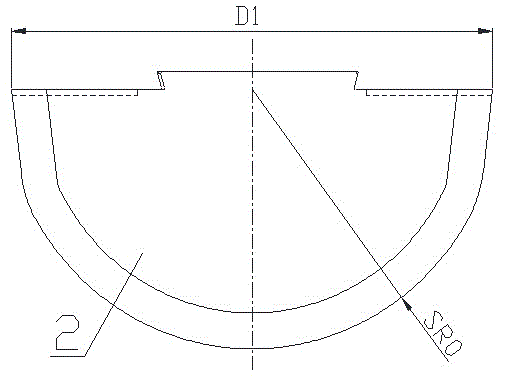

[0035] Step two, such as figure 2 , image 3 and Figure 4 As shown, the special wedge-shaped hammer head 2 and the lower die 3 when making the prefabricated blank. The wedge-shaped hammer head 2 is a cylindrical body with a circular arc surface, which is used for the initial forging of the inner spherical surface of the bottom head, so that the blank can be aligned with the concave The mold 3 is positioned, and the wedge-shaped hammer head 2 is manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com