Guide rail and sliding block transmission mechanism for forging

A technology of guide rail slider and transmission mechanism, which is applied in the field of guide rail slider transmission mechanism and forging guide rail slider transmission mechanism, which can solve the problems of low production efficiency, large energy consumption, and low forging efficiency, and achieve high production efficiency and low energy consumption. less, high forging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

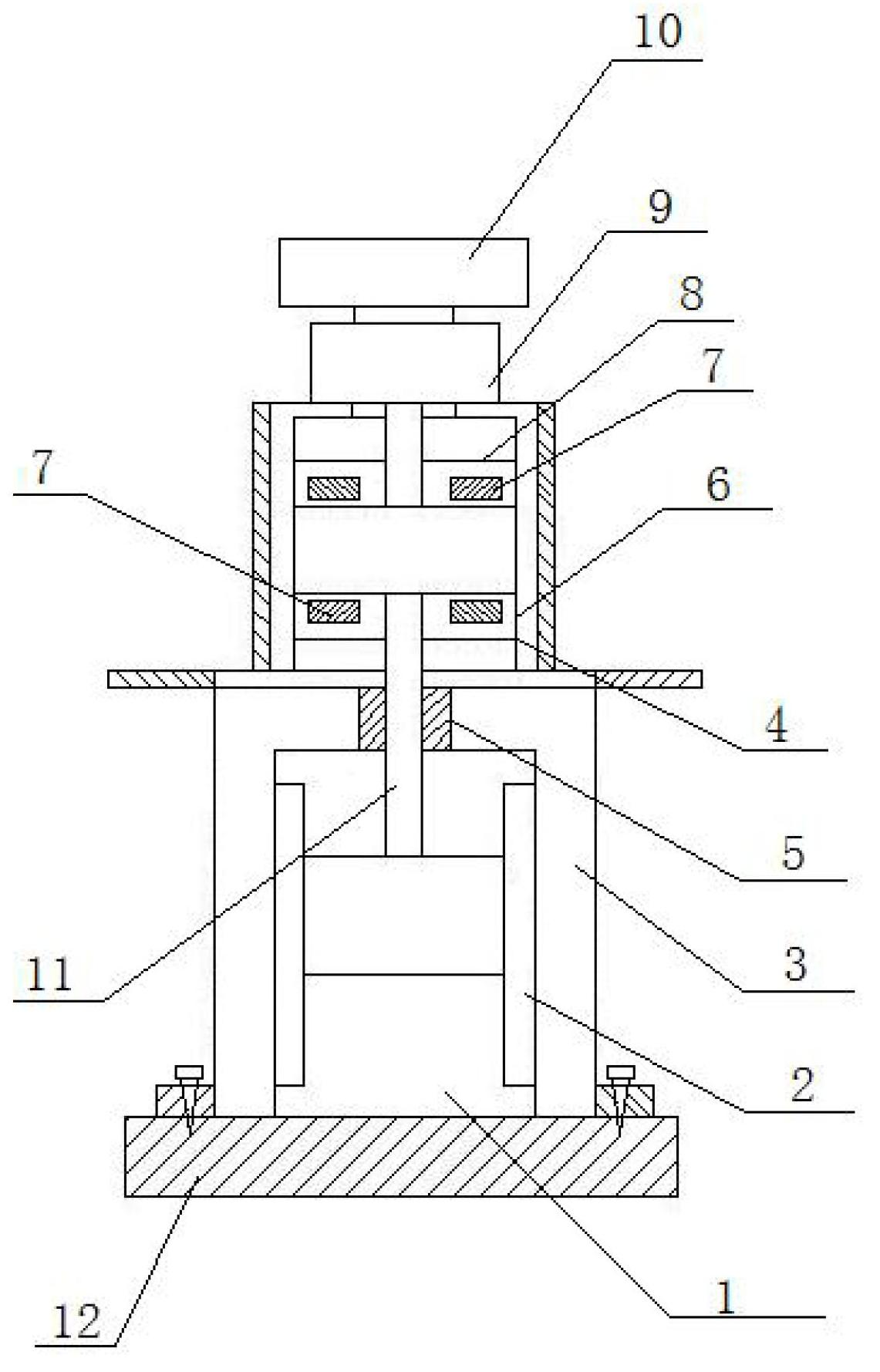

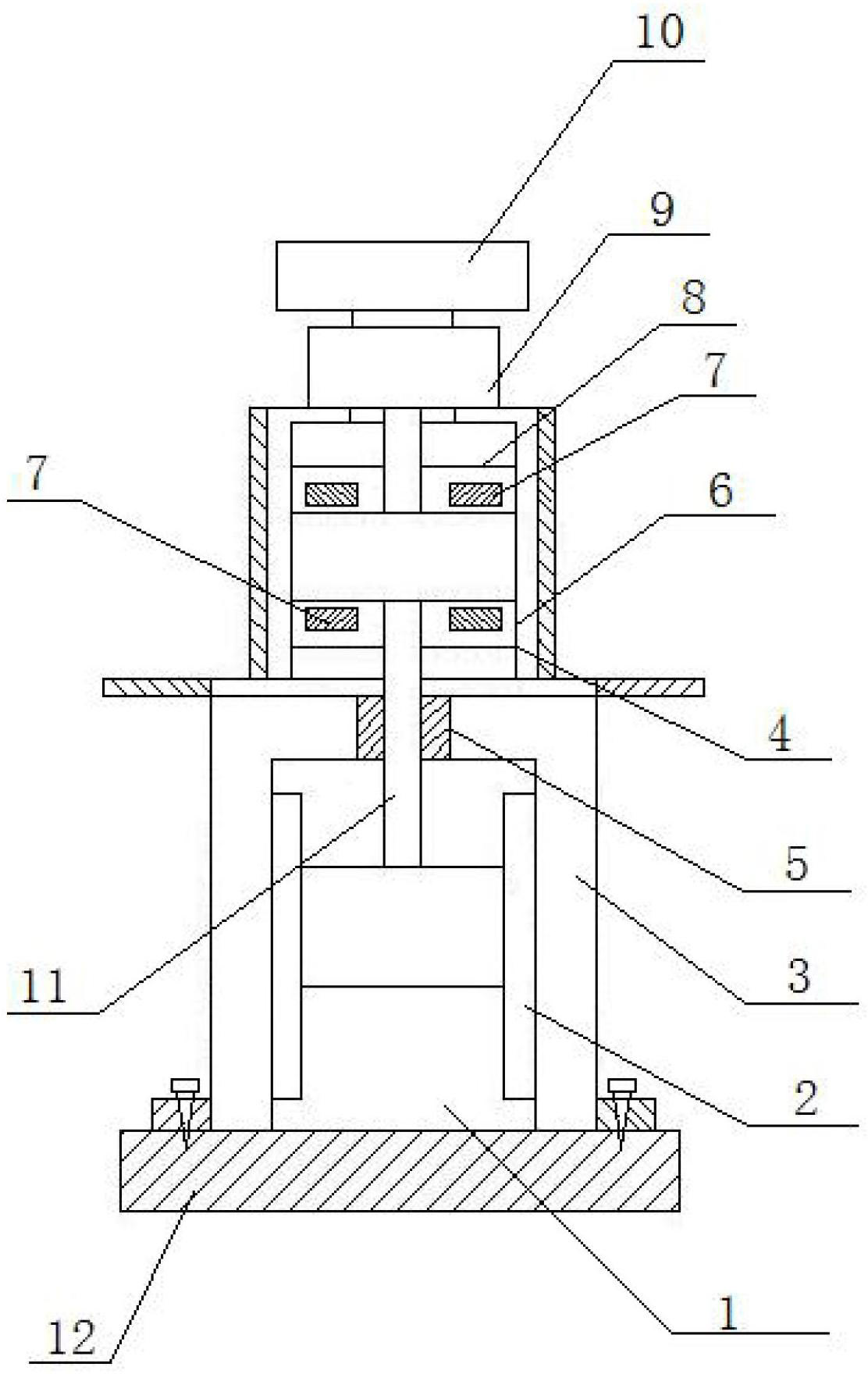

[0009] The guide rail slider transmission mechanism has a slider (1), the slider (1) is installed on the mechanism body (3) through the double-action guide rail (2), and a sliding bearing (5) is installed on the top of the mechanism body (3). The drive shaft (11) passes through the slider bearing (5) and connects with the slider (1) through the bottom of the transmission drive shaft (11), and the transmission drive disc (6) is installed on the transmission drive shaft (11) ), a high-energy magnet (7) is connected to the transmission drive plate (6), the polarity of the high-energy magnet (7) is opposite, and it is symmetrically embedded in the transmission drive plate (6); on the top of the mechanism body (3) is installed a square Bracket (4), the centerline of the square bracket (4) is concentric with the centerline of the transmission drive disk (6), and the transmission drive disk (6) is connected with a dual-frequency rotating disk (8), a dual-frequency rotating disk (8) I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com