Preparation method for TNM alloy forging blank with uniform structure

A technology with uniform structure and forged billets, which is applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of high forging temperature, increase the cost of forging billet preparation, rough forging billet structure, etc., and achieve forging The effect of low temperature, avoiding cracking phenomenon, and improving the uniformity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

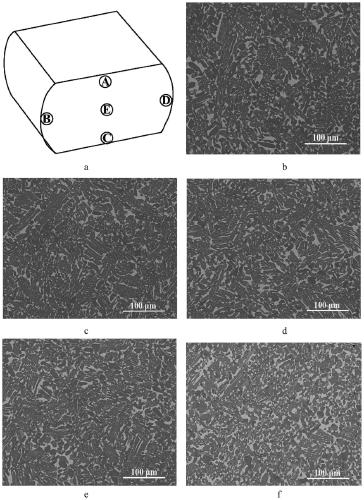

[0034] This embodiment is a method for preparing a TNM alloy forging billet with uniform structure.

[0035] The nominal composition of the TNM alloy described in this implementation example is Ti-43Al-4Nb-1Mo-0.2B, the composition is atomic percentage, and the size of the ingot used is Φ73×99mm.

[0036] The specific process of this embodiment is as follows:

[0037] The first step is preparation before forging. The ingot to be die-cast is a cylindrical sample, and the surface of the ingot to be die-cast is polished to ensure that the surface quality is good and free of defects. Ultrasonic flaw detection is used to confirm that there is no crack inside the ingot, and Y is evenly coated on the surface of the ingot 2 o 3 slurry to avoid surface oxidation of the ingot. After the coating is air-dried, the ingot to be die-cast is wrapped. The sheath is composed of a hollow cylindrical sleeve and two end caps. The material of the sheath is stainless steel with a thickness of 5...

Embodiment 2

[0052] This embodiment is a method for preparing a TNM alloy forging billet with uniform structure.

[0053] The nominal composition of the TNM alloy described in this implementation example is Ti-43Al-4Nb-1Mo-0.2B, the composition is atomic percentage, and the size of the ingot used is Φ73×99mm.

[0054] The specific process described in this embodiment is as follows:

[0055] The first step is preparation before forging. The ingot to be die-cast is a cylindrical sample, and the surface of the ingot to be die-cast is polished to ensure that the surface quality is good and free of defects. Ultrasonic flaw detection is used to confirm that there is no crack inside the ingot, and Y is evenly coated on the surface of the ingot 2 o 3 slurry to avoid surface oxidation of the ingot. After the coating is air-dried, the ingot to be die-cast is wrapped. The sheath is composed of a hollow cylindrical sleeve and two end caps. The material of the sheath is stainless steel with a thic...

Embodiment 3

[0070] This embodiment is a method for preparing a TNM alloy forging billet with uniform structure.

[0071] The nominal composition of the TNM alloy described in this implementation example is Ti-43Al-4Nb-1Mo-0.2B, the composition is atomic percentage, and the size of the ingot used is Φ73×99 mm.

[0072] The specific process described in this embodiment is as follows:

[0073] The first step is preparation before forging. The ingot to be die-cast is a cylindrical sample, and the surface of the ingot to be die-cast is polished to ensure that the surface quality is good and free of defects. Ultrasonic flaw detection is used to confirm that there is no crack inside the ingot, and Y is evenly coated on the surface of the ingot 2 o 3 slurry to avoid surface oxidation of the ingot. After the coating is air-dried, the ingot to be die-cast is wrapped. The sheath is composed of a hollow cylindrical sleeve and two end caps. The material of the sheath is stainless steel with a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com