Autocar spindle fork vertical type forging technique method

A technology for automobile steering knuckle and steering knuckle fork, which is applied to steering mechanism, steering tie rod, vehicle parts, etc., can solve the problem of high cost of parts, reduce the parting area, improve the forging efficiency, and optimize the blanking process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

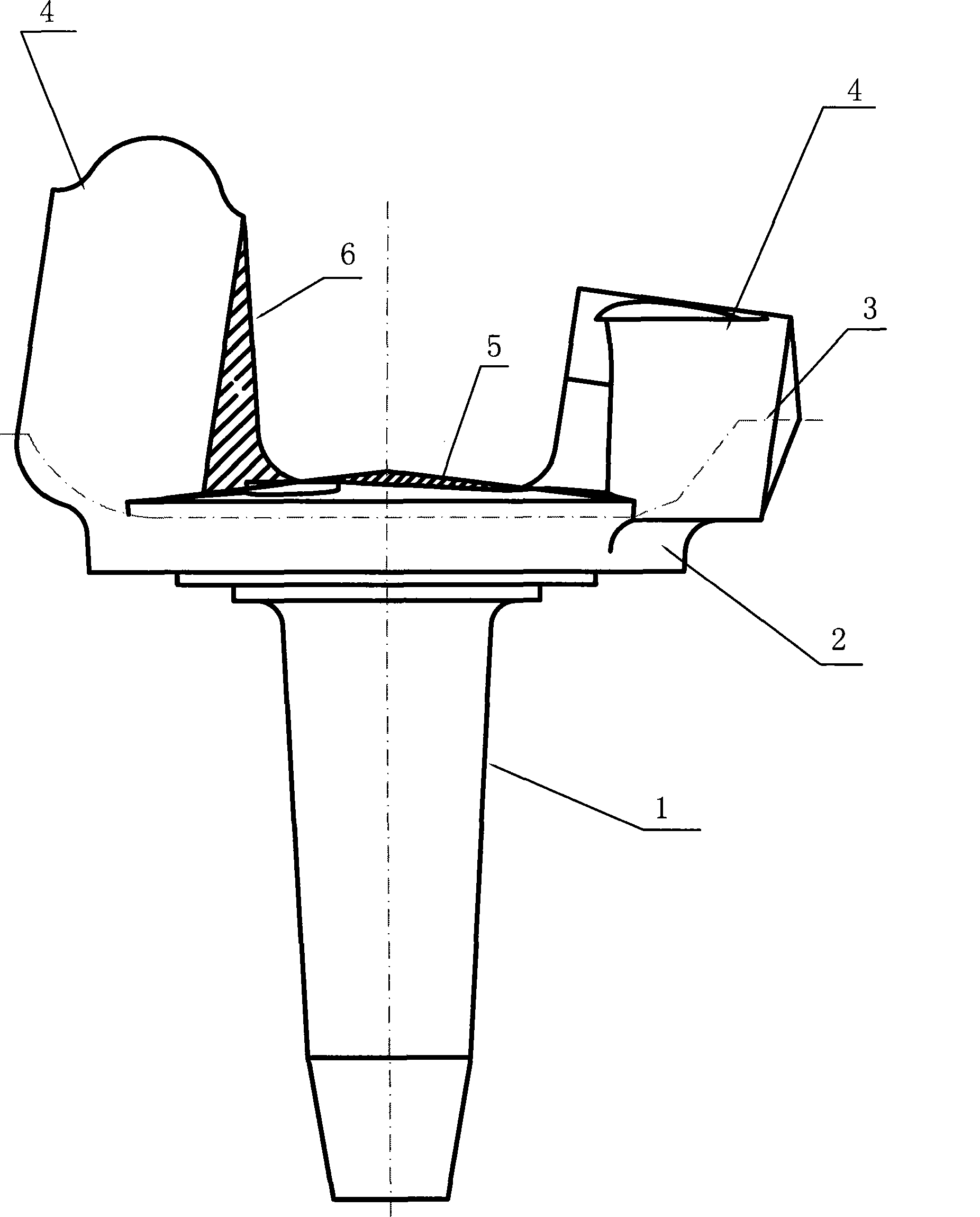

[0007] Combine figure 1 The illustrated automobile steering knuckle yoke further describes the present invention as follows: the automobile steering knuckle yoke is formed as a whole by the rod part 1, the flange plate 2, and the symmetrical fork lugs 4 on the flange plate. The specific content of the vertical forging process method is: a. From the automobile steering knuckle flange 2. Taking into account the fork lugs 4 on both sides, the vertical mold is divided, and the mold parting surface 3 of the vertical mold is perpendicular to the rod; The fork lug inner gear 6 of the steering knuckle fork is supplemented to form a draft angle; b, then vertical forging is performed on a forging machine; the fork lug inner gear bottom 5 is directly forged to form.

[0008] The draft angle is generally 2° to 3°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com