Multidirectional die-forging forming die and forming method of valve forge part with main flange

A multi-directional die forging and forming die technology, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. The effect of improving forging efficiency, reducing forging weight and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below with reference to accompanying drawing and embodiment:

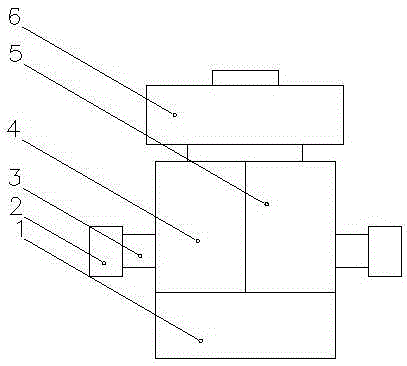

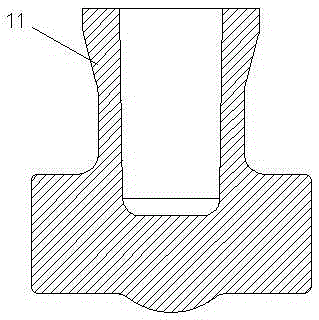

[0044] attached Figure 1-8 It can be seen that a multi-directional die forging forming die with a main flange valve body forging,

[0045] Including a lower mold 1, the upper part of the lower mold 1 is provided with a left mold 4 and a right mold 5;

[0046] The left mold 4 is connected with the left horizontal cylinder 2 through the left horizontal connecting rod 3;

[0047] The right mold 5 is connected with the right horizontal cylinder 2 through the right horizontal connecting rod 3;

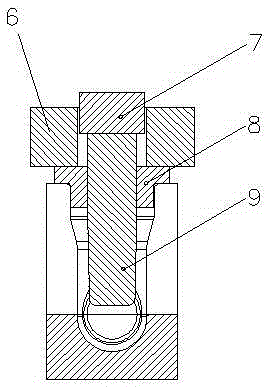

[0048] An upper mold 8 is arranged above the left mold 4 and the right mold 5;

[0049] The upper mold 8 is connected with the backing plate 6 of the upper mold; the upper backing plate 6 of the upper mold is connected with the moving beam;

[0050] The middle part of the upper mold 8 is provided with a through hole;

[0051] The middle part of the backing plate 6 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com