Multi-station forging device for small blank workpieces

A blank and multi-station technology, applied to forging/pressing/hammer devices, manufacturing tools, metal processing equipment, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

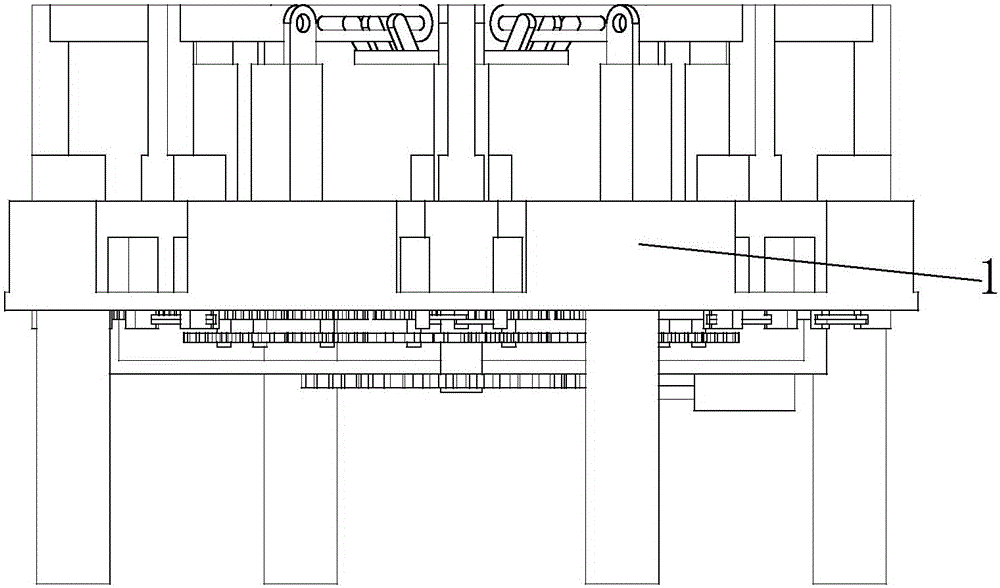

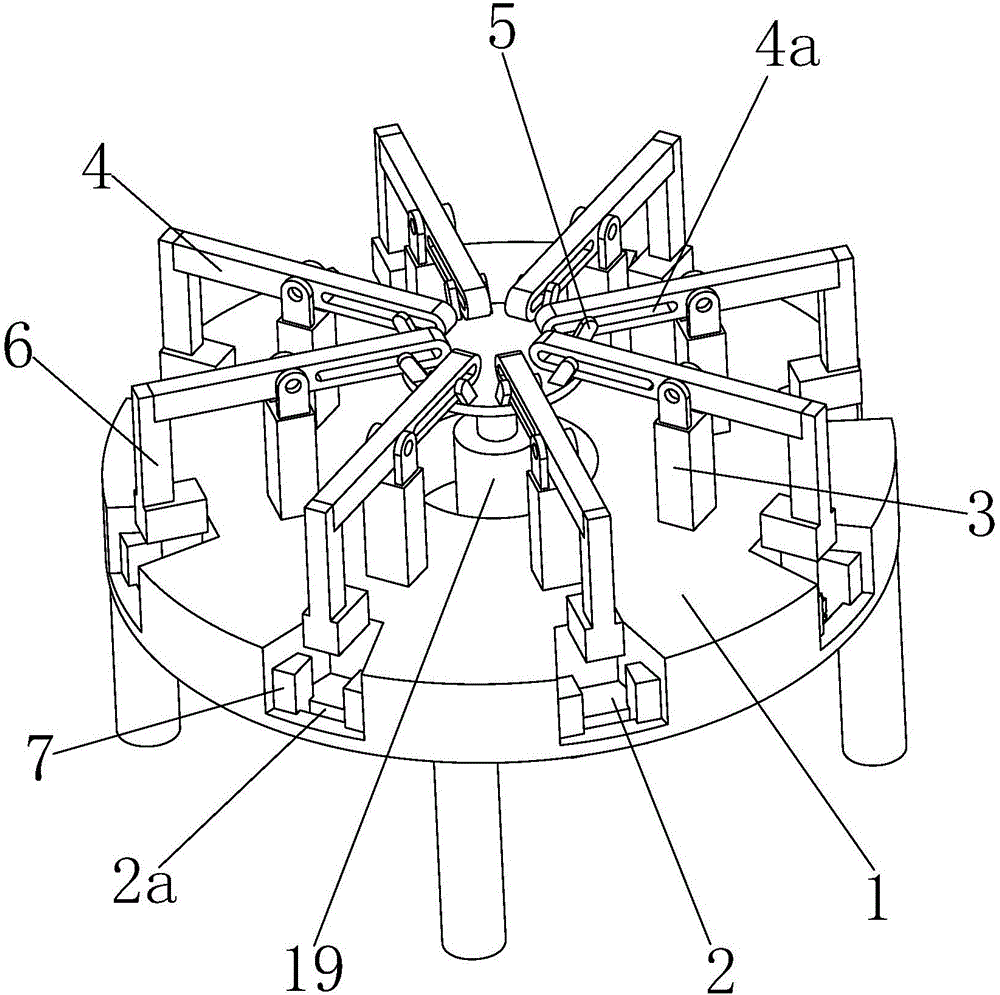

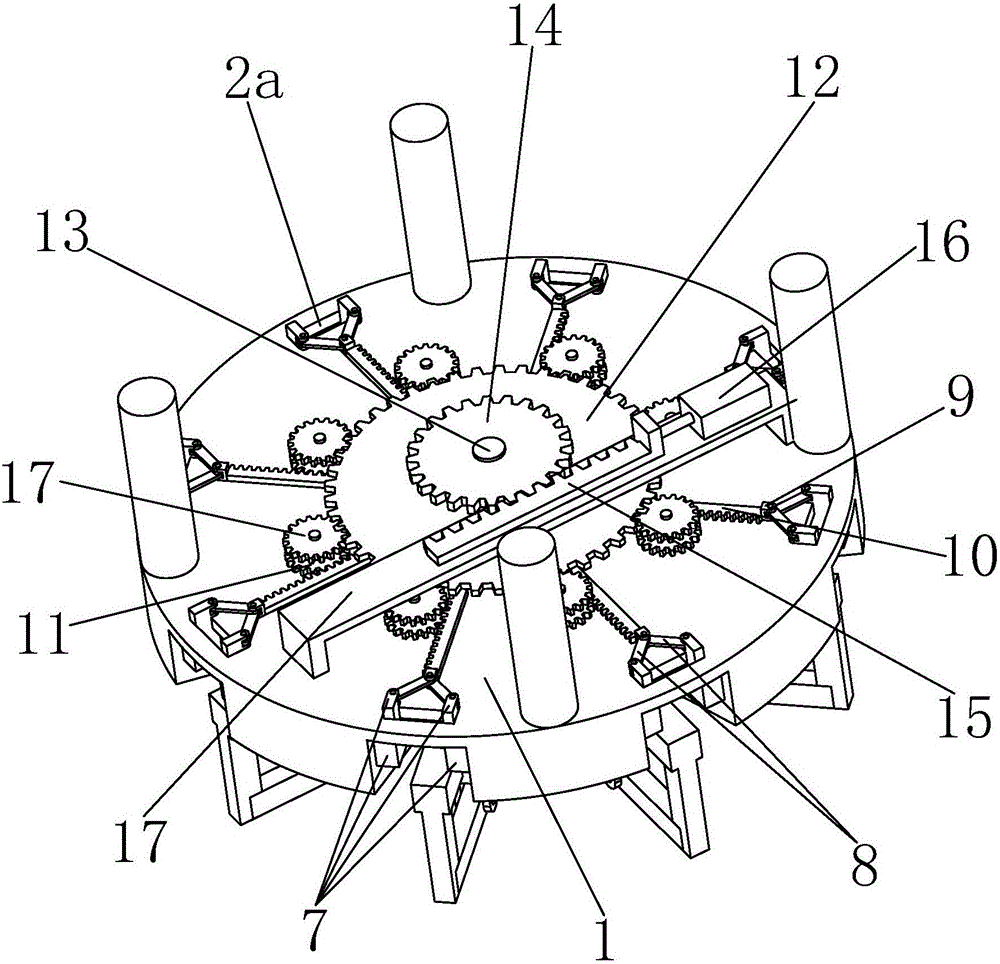

[0017] Such as Figure 1 to Figure 3 As shown, a multi-station forging device for small blanks includes a circular carrier 1, and a plurality of station slots 2 are evenly distributed on the arc surface of the carrier 1. The carrier 1 The upper end is fixed with a ring-shaped fixed frame 3, and the upper ends of the fixed frame 3 are hingedly installed with a horizontal frame 4, and the horizontal frame 4 is provided with a waist-shaped chute 4a, and the center position of the upper end of the carrier frame 1 is installed There is a stroke hydraulic cylinder 19, and the stroke hydraulic cylinder 19 is fixedly connected with a plurality of transfer rods 5, and the upper ends of the transfer rods 5 are all correspondingly slidably installed in the waist-shaped chute 4a, and the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com