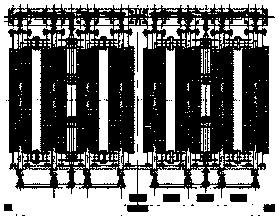

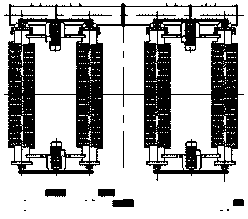

Laminar cooling process control device and method for hot rolled strip steel

A laminar cooling, hot-rolled strip technology, applied in temperature control and other directions, can solve the problems of uneven temperature distribution and distribution of microstructure and properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

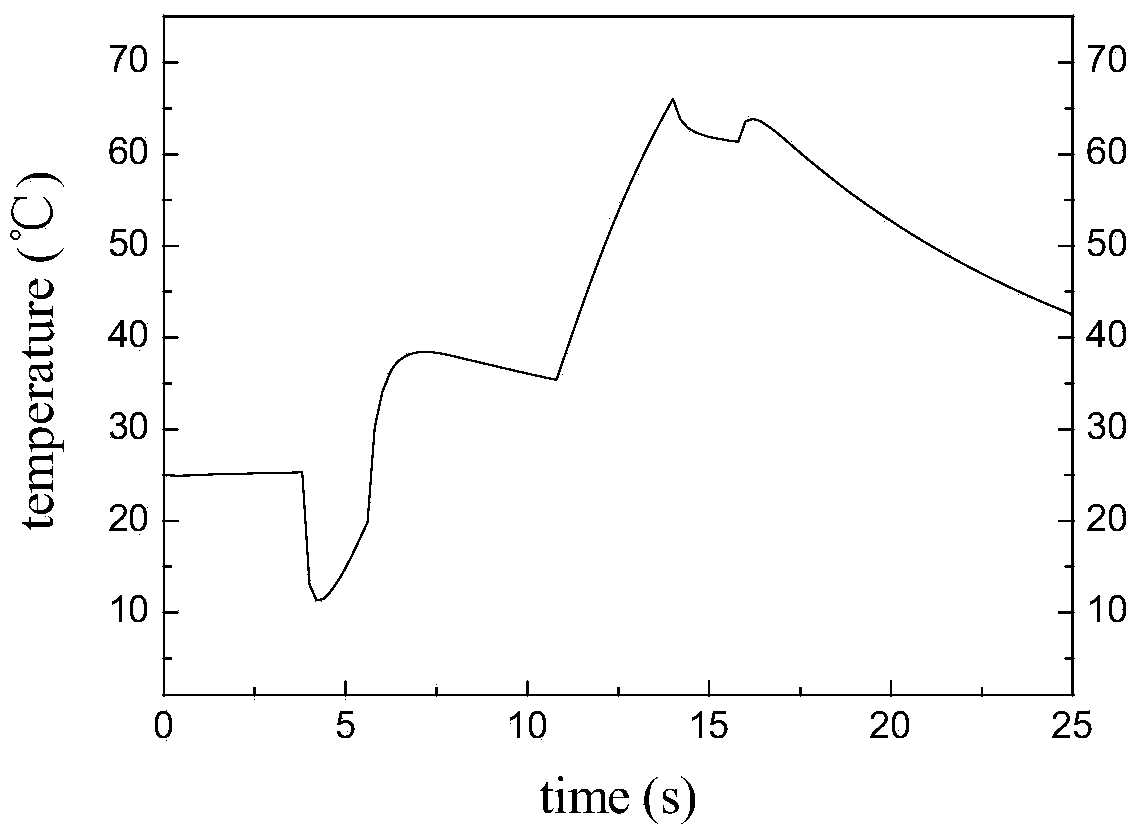

Embodiment 1

[0084] Example 1: For beam steel with a specification of 1900mm×8mm, the temperature after finish rolling is 860°C, the required coiling temperature is 620°C, and the running speed during cooling is 4.5m / s. After MARC finite element software simulation, it is determined that the laminar cooling mode of this specification is 110-1111000000 (manifold opening and closing mode in the laminar cooling area, 3 groups in the strong cooling area, 2 groups before opening, and 10 groups in the slow cooling area, 4 groups before opening ). During the laminar cooling process, the edge shielding process is applied in the slow cooling zone, and the shielding amount is 0mm. The temperature of the steel plate after cooling is roughly around the required crimping temperature of 620°C. The simulation results are: the temperature in the middle of the steel plate is 630°C, and the temperature at the edge is 574°C. The temperature difference in the width direction was 56°C.

Embodiment 2

[0085] Embodiment 2: For beam steel with a specification of 1900mm×8mm, the temperature after finish rolling is 860°C, the required coiling temperature is 620°C, and the running speed during cooling is 4.5m / s. After MARC finite element software simulation, it is determined that the laminar cooling mode of this specification is 110-1111000000 (manifold opening and closing mode in the laminar cooling area, 3 groups in the strong cooling area, 2 groups before opening, and 10 groups in the slow cooling area, 4 groups before opening ). In the process of laminar cooling, the edge shielding process is applied in the slow cooling zone, the shielding amount is 100mm, and the temperature of the steel plate after cooling is roughly around the required crimping temperature of 620°C. The simulation results are: the temperature in the middle of the steel plate is 630°C, and the temperature at the edge is 589°C. The temperature difference in the width direction was 41°C.

Embodiment 3

[0086] Example 3: For beam steel with a specification of 1300mm×5mm, the temperature after finish rolling is 860°C, the required coiling temperature is 620°C, and the running speed during cooling is 7m / s. After MARC finite element software simulation, it is determined that the laminar cooling mode of this specification is 110-1111000000 (manifold opening and closing mode in the laminar cooling area, 3 groups in the strong cooling area, 2 groups before opening, and 10 groups in the slow cooling area, 4 groups before opening ). In the process of laminar cooling, the edge shielding process is applied in the slow cooling zone, and the shielding amount is 0mm. The temperature of the steel plate after cooling is roughly around the required crimping temperature of 620°C. The simulation results are: the temperature in the middle of the steel plate is 630°C, and the temperature at the edge is 588°C. The temperature difference in the width direction was 42°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com