Accurate forming method of special-shape deep-hole type parts

A precision forming, deep hole technology, applied in the field of metal machining, can solve the problems of complex shape, short service cycle, large casting pollution, etc., to achieve the effect of dense internal structure, improved product strength, and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

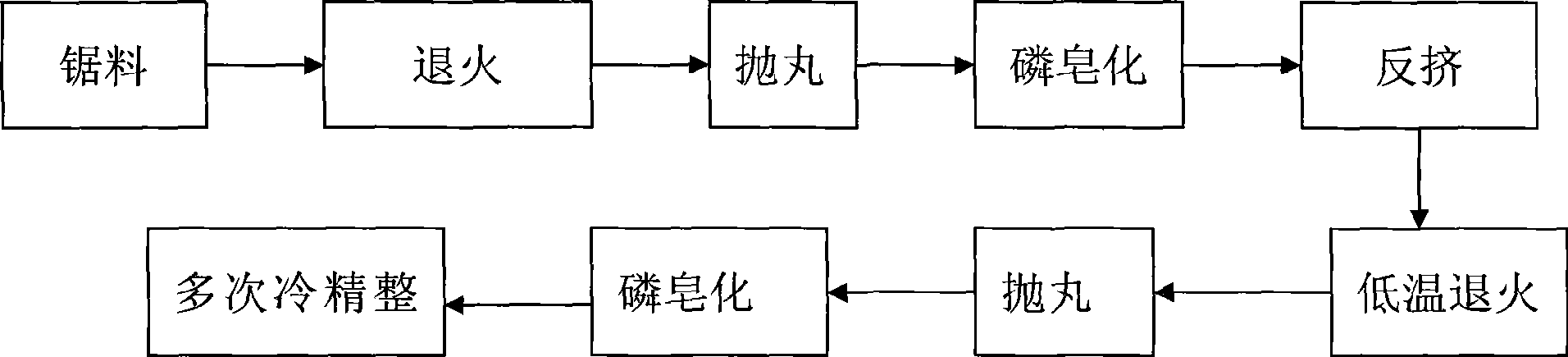

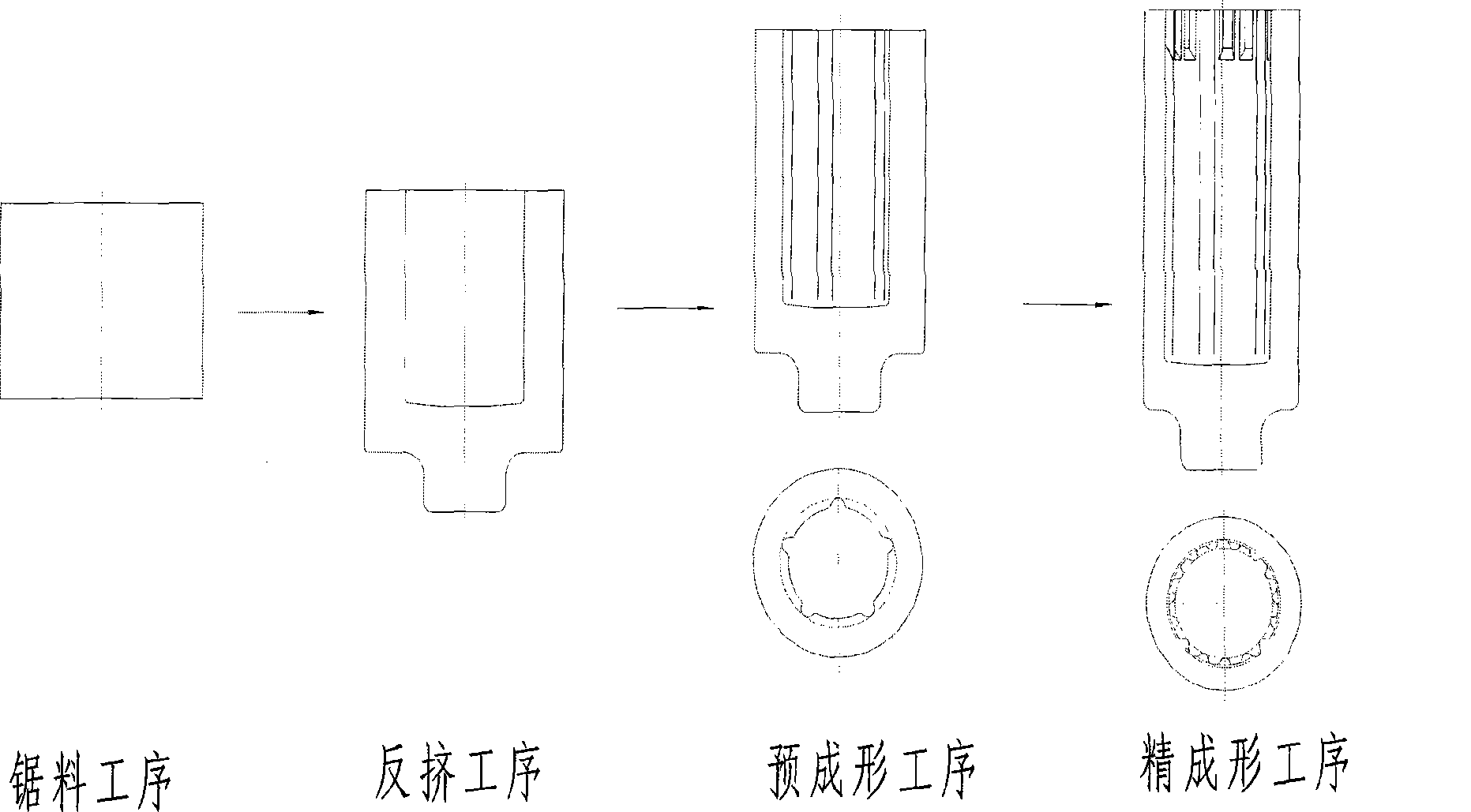

[0015] Taking the processing process of the push rod as an example, the technological process is as follows:

[0016] 1. For sawing, choose a hot-rolled round bar with a diameter of φ48.7 mm, the material grade is 20MnCr5, adjust the cutting length, and control the weight at 610-620 grams;

[0017] 2. Conventional spheroidizing annealing process, put the blank into the annealing furnace, heat it to 770°C±20°C, keep it warm for 4 hours, cool it to 500°C with the furnace, take it out of the furnace, and air cool it to room temperature;

[0018] 3. In the conventional shot blasting process, use 70% sharp sand and 30% steel shots to blast the blank for 20 to 40 minutes to remove oil, rust, burrs, etc. on the surface of the blank;

[0019] 4. Conventional phosphorus saponification process;

[0020] 5. Back-extrusion, cold forging and back-extrusion method is used to complete the pre-forming of deep holes with large deformation at one time, from billet diameter φ48.7mm to outer dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com