Method for controlling medium plate quenching technology

A control method and process technology, applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problem of weak theoretical basis for heat transfer coefficient calculation, gap between model establishment basis and calculation accuracy, and accurately describe the steel plate water cooling temperature drop process And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

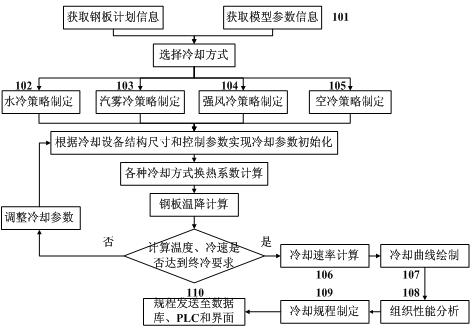

[0034] The present invention is a method for controlling the quenching process of medium and thick plates, which is suitable for the quenching of steel plates on a quenching machine. figure 1 , including the following steps:

[0035] The first step 101 is to read the steel plate plan information stored in the factory-level MES or plan management system database according to the PLC tracking trigger, including steel plate specification, steel type, plate number, heat treatment mode, alloy composition and target process parameters; and then according to the plan information Call the model parameters in the database of the quenching control system, including steel plate thermophysical parameters (specific heat, thermal conductivity, linear expansion coefficient and density), default values of process parameters and combination classification information (steel group number, classification number and layer number) ;Call the cooling method calculation model according to the plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com