Infrared temperature detecting device and method for wire material plasma arc additive manufacturing

An infrared temperature, plasma arc technology, applied in plasma welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of destroying the workpiece to be welded, unable to apply, unable to control the grain size, etc., to improve the forming quality and dimensional accuracy. , the uniformity of tissue properties and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

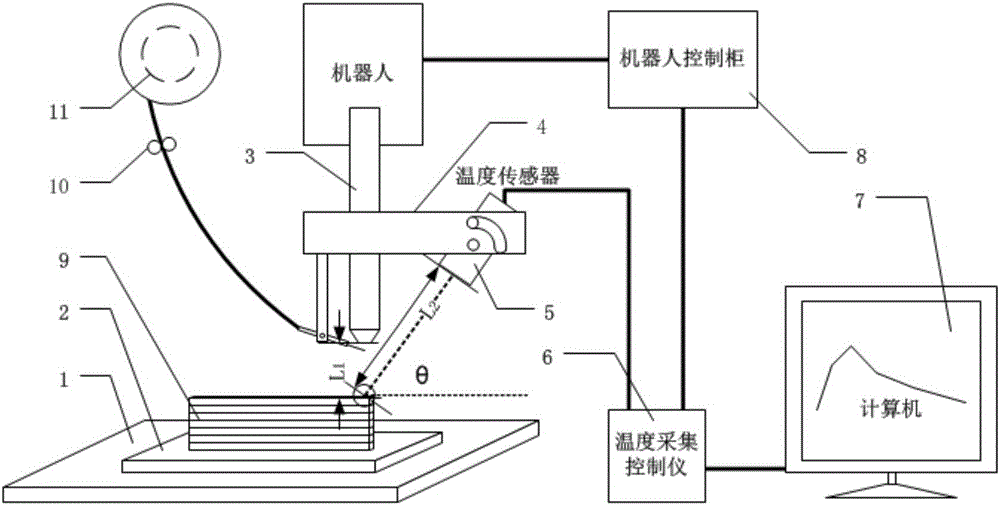

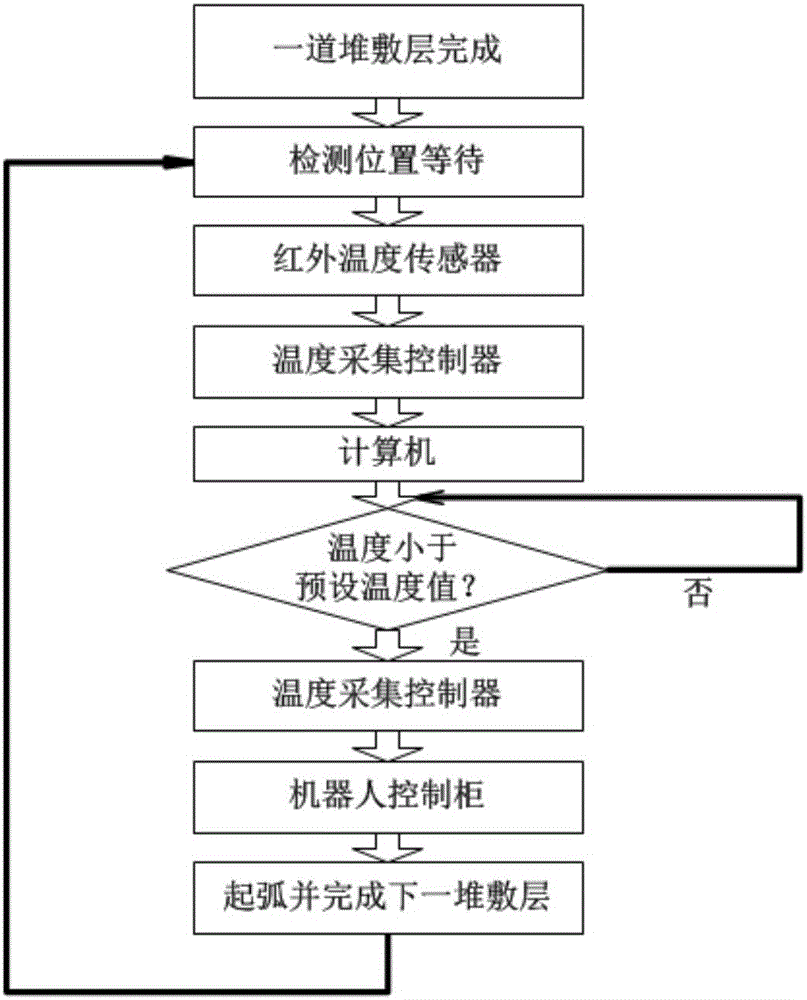

[0030] The present invention provides a detection method for detecting temperature of an infrared temperature sensing device manufactured by using the above-mentioned plasma arc additive manufacturing, and the specific implementation steps are as follows:

[0031] Step 1: After a deposition layer is completed, the infrared temperature sensor moves to the interlayer temperature measurement position. The plasma welding torch, temperature sensor and deposition layer are located on the same vertical plane, and the welding torch is located directly above the starting point of the deposition layer. The distance from the starting point L 1 is 80mm, the angle between the temperature sensor and the horizontal direction is 45°, and the distance L from the starting point of the lay-up layer 2 is 200mm, the robot executes the waiting command and starts temperature measurement;

[0032] Step 2: The infrared temperature sensor emits a laser positioning point to locate the starting point of...

Embodiment 2

[0038] The present invention provides a detection method for detecting temperature of an infrared temperature sensing device manufactured by using the above-mentioned plasma arc additive manufacturing, and the specific implementation steps are as follows:

[0039] Step 1. After one deposition layer is completed, the infrared temperature sensor moves to the interlayer temperature measurement position. The plasma welding torch, temperature sensor and deposition layer are located on the same vertical plane, and the welding torch is located directly above the starting point of the deposition layer. The distance from the starting point is L 1 is 100mm, the angle between the temperature sensor and the horizontal direction is 60°, and the distance L from the starting point of the current layup layer 2 is 180mm, the robot executes the waiting command and starts temperature measurement;

[0040] Step 2, the infrared temperature sensor emits a laser positioning point to locate the star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com