Ultrasonic field coupled laser-MIG common welding pool aluminum alloy welding technology

A welding technology and ultrasonic coupling technology are applied in the field of aluminum alloy laser-MIG hybrid welding technology to achieve the effect of eliminating pores and improving microstructure and properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

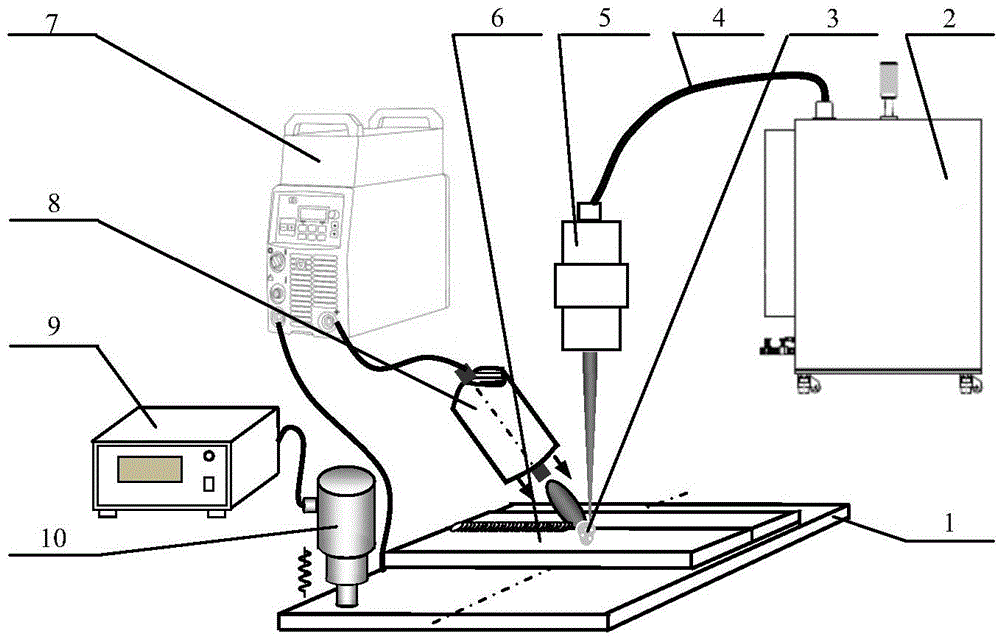

[0019] combine figure 1 : In the figure 1. Backing plate, 2. Laser generator, 3. Welding pool, 4. Operating optical fiber, 5. Laser welding head, 6. Aluminum alloy butt test plate, 7. Welding power supply, 8. MIG welding torch, 9 . Ultrasonic generator, 10. Ultrasonic vibration head.

[0020] Taking the mechanical vibration ultrasonic field coupling laser-MIG eutectic pool aluminum alloy welding technology as an example, place an aluminum alloy butt test plate 6 to be welded on the backing plate 1, the material is A7N01 plate, and the positive electrode of the welding power supply 7 passes through the MIG welding torch 8 The welding wire is connected, and the negative electrode of the welding power supply 7 is connected with the backing plate 1. After arcing, the arc heats the aluminum alloy butt joint test plate 6 to form a welding pool 3. At the same time, the laser light emitted by the laser generator 2 is transmitted to the laser welding head 5 through the operating optic...

Embodiment 2

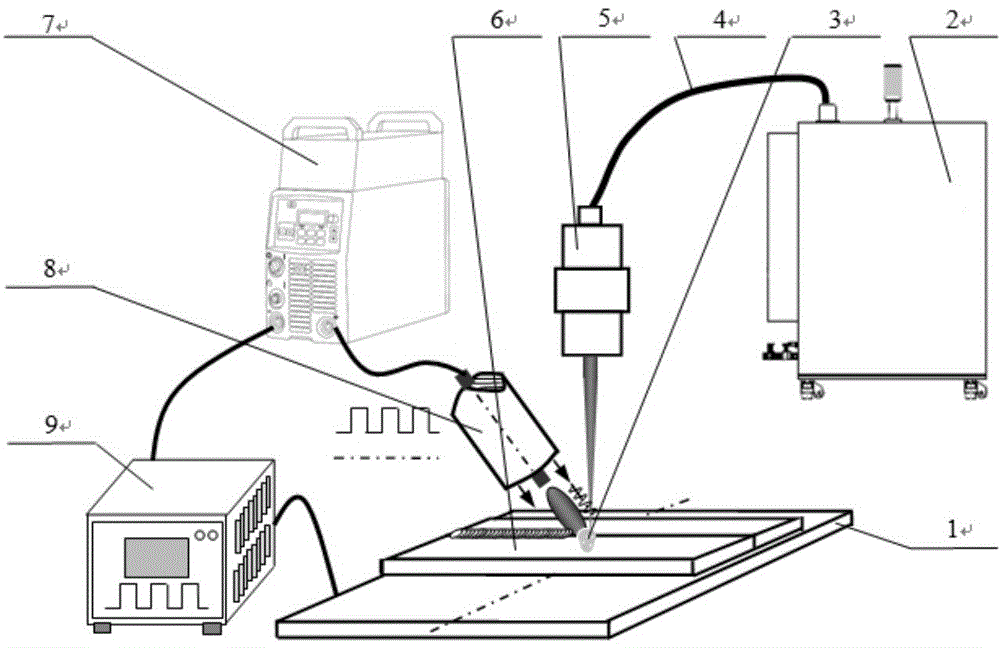

[0022] combine figure 2 , in the figure 1. Backing plate, 2. Laser generator, 3. Welding pool, 4. Operating optical fiber, 5. Laser welding head, 6. Aluminum alloy butt test plate, 7. Welding power supply, 8. MIG welding torch, 9 . Ultrasonic frequency pulse power supply.

[0023] Taking the ultrasonic arc coupled laser-MIG eutectic pool aluminum alloy welding technology as an example, an aluminum alloy butt test plate 6 is placed on the backing plate 1, the positive electrode of the welding power supply 7 is connected to the welding wire of the MIG welding gun 8, the negative electrode of the welding power supply 7 is connected to the ultrasonic frequency The pulse power supply 9 is connected, and the negative pole of the ultrasonic frequency pulse power supply 9 is connected to the backing plate 1. During welding, since an ultrasonic frequency pulse power supply 9 is superimposed on the traditional MIG welding welding power supply 7, the ultrasonic frequency pulse power sup...

Embodiment 3

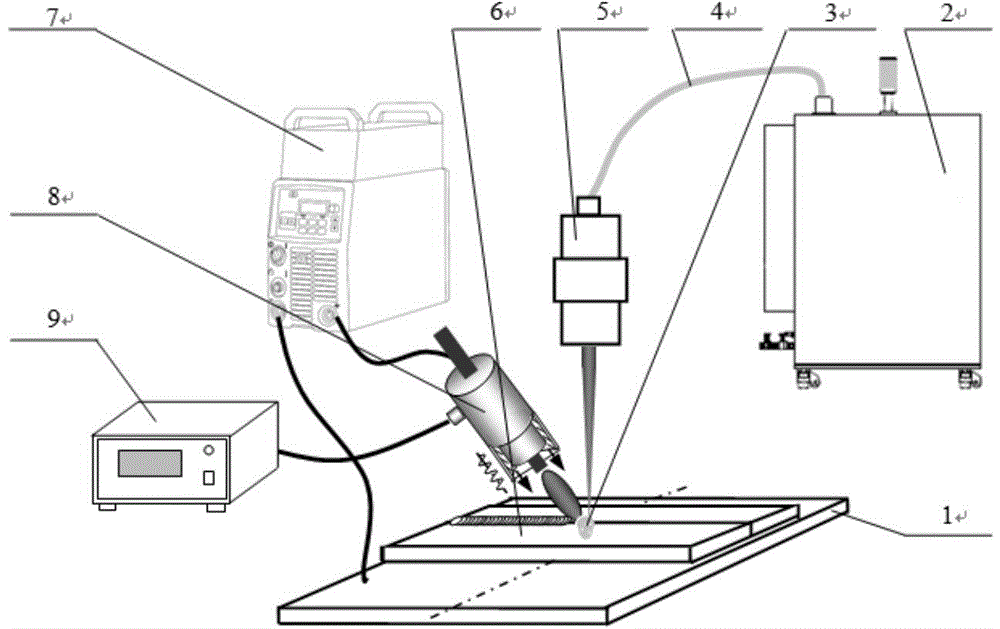

[0025] combine image 3 , in the figure 1. Backing plate, 2. Laser generator, 3. Welding pool, 4. Operating optical fiber, 5. Laser welding head, 6. Aluminum alloy butt test plate, 7. Welding power supply, 8. Ultrasonic-MIG composite Welding gun, 9. Ultrasonic transmitter.

[0026] Taking the ultrasonic composite welding torch coupling laser-MIG eutectic pool aluminum alloy welding technology as an example, the aluminum alloy butt test plate 6 to be welded is placed on the backing plate 1, and the positive electrode of the welding power supply 7 is connected to the welding wire in the ultrasonic-MIG composite welding torch 8 , the negative pole of the welding power supply 7 is connected to the backing plate 1. The ultrasonic transmitter 9 is connected with the ultrasonic transducer in the ultrasonic-MIG composite welding torch 8, through the piezoelectric conversion of the transducer, the electric energy is converted into ultrasonic vibration, and transmitted to the The end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com