Manufacturing method of high-quality cold heading steel with uniform structure property

A technology of structure performance and manufacturing method, applied in the field of medium carbon cold heading steel wire rod production, can solve the problems of low processing rate, uneven structure of wire rod, cracking during cold heading processing, etc., so as to improve the qualification rate and reduce the problem of cold heading cracking. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 uses a billet with a cross-section of 150×150mm, the finished product specification is Φ8mm, and the composition is shown in Table 1. The temperature of the billet out of the furnace is 1060°C, and the spinning temperature is 825°C. The rolling process and Stelmore air cooling The controlled cooling process is shown in Table 2, and the mechanical properties are shown in Table 3.

Embodiment 2

[0027] Example 2 uses a billet with a cross-section of 150×150mm, the finished product specification is Φ12mm, and the composition is shown in Table 1. The billet temperature is 1050°C, and the spinning temperature is 820°C. The controlled cooling process is shown in Table 2, and the mechanical properties are shown in Table 3.

[0028] Table 1 Chemical composition (wt, %)

[0029] Element C mn Si Cr P S Cu Ni Mo Alt Example 1 0.35 0.63 0.22 0.97 0.011 0.002 0.07 0.05 0.16 0.026 Example 2 0.35 0.65 0.25 0.98 0.019 0.006 0.08 0.04 0.17 0.031

[0030] In Table 1, except for the ingredients listed in the table, the rest are Fe and trace impurity elements.

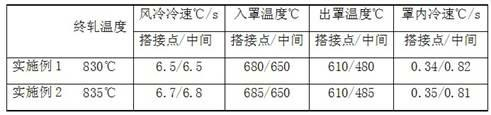

[0031] Table 2 Controlled rolling and controlled cooling process

[0032]

[0033] "Middle" in Table 2 means "non-lap point".

[0034] Table 3 Mechanical Properties

[0035] Tensile strength MPa Elongation% rate of reduction in area% Vickers h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com