Rolling device for preparing high-toughness high-formability magnesium alloy sheet strip coil

A magnesium alloy and formability technology, applied in the field of thin strip coil rolling devices, can solve the problems of difficult control of plate thickness accuracy, inability to guarantee rolling temperature, and small deformation temperature range, so as to avoid poor plate shape and good surface quality , the effect of organizational performance satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

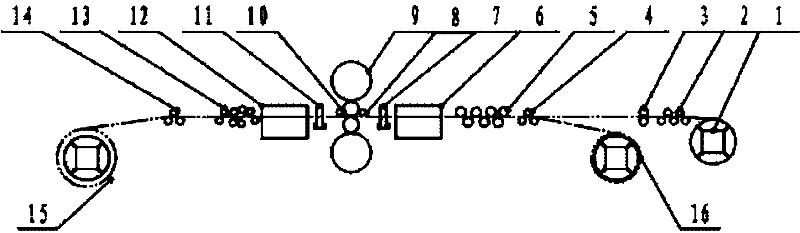

[0026] Put the coil to be rolled into the uncoiler 1, rotate the uncoiler at the strip threading speed, and at the same time complete the opening, uncoiling, and straight-end feeding of the magnesium alloy coil billet with the straight-end machine 2. Ensure that the tension required for rolling is generated on the strip during decoiling and rolling, and the strip can be centered so that the centerline of the width of the strip and the centerline of the unit can be kept coincident.

[0027] The strip is pushed forward, passes through the guide pinch roller 3, enters the first guide tension roller 4, enters the straightening machine 5 for straightening, enters the first online heating device 6 for online heating of the strip, and enters the first thickness gauge 7. Measure the thickness of the incoming material, pass through the first roll heating and lubricating device 8, enter the main rolling mill 9 for rolling, pass through the second roll heating and lubricating device 10 af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com