A rolling production line temperature control device process equipment

A technology of temperature control device and process equipment, applied in metal processing equipment, workpiece surface treatment equipment, metal rolling and other directions, can solve the problems of large cross section, difficult to achieve temperature control rolling, reduce production line efficiency, etc., to improve product performance , improve product competitiveness, increase the effect of output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

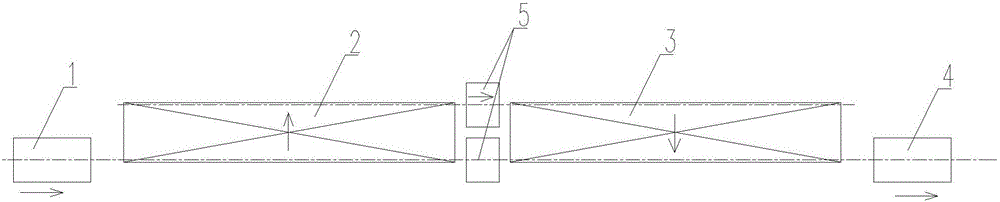

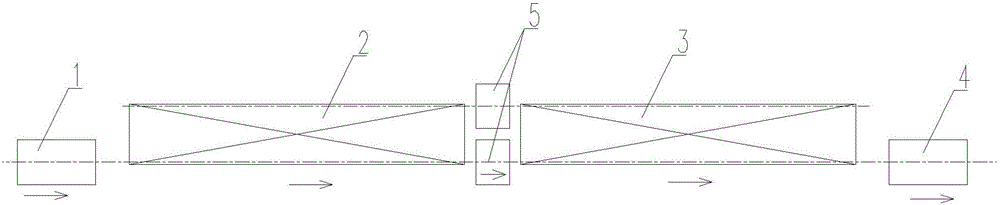

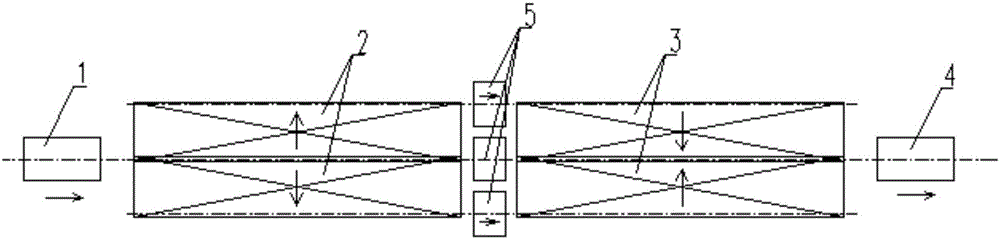

[0028] As shown in the figure, a rolling production line temperature control device process equipment includes rolling mill I1, temperature control stand I2 and rolling mill II4 connected in sequence, the output end of the rolling mill I is connected to the input end of the temperature control stand I , the output end of the temperature control platform I is connected with the input end of the rolling mill II. In this example, by setting a temperature control stand between the two rolling mills, the online temperature of large-size rolled pieces can be effectively controlled, and low-temperature rolled pieces with uniform cross-sections can be obtained to achieve tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com