A temperature-controlled rolling process for medium and large size rolled pieces

A temperature-controlled rolling and large-scale technology, which is applied in the field of metallurgy, can solve the problems of difficult heat in the core, lengthening of the rolling line, uneven section structure of the rolled piece, etc., and achieve the effects of improving production efficiency, improving product performance, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

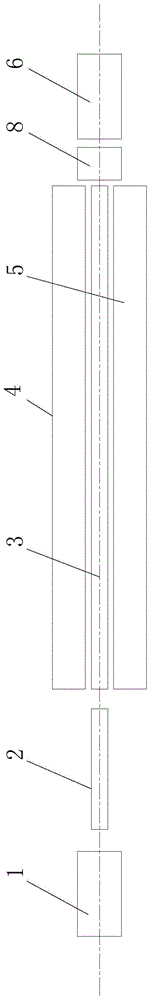

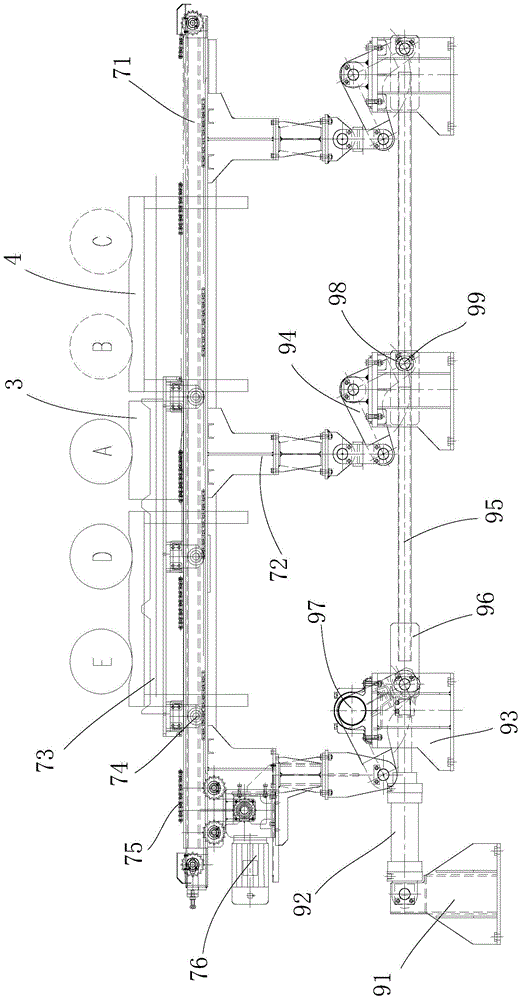

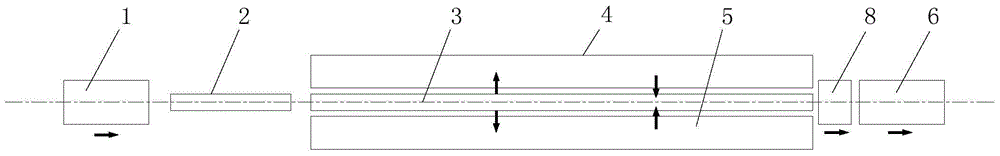

[0052] The implementation of the invention will be described by specific specific examples below. People familiar with this technology can easily understand other advantages and effects of the invention from the content disclosed in this specification. The arrow in the figure shows the running direction of the rolled piece.

[0053] Such as figure 1 and figure 2 As shown, the present invention provides a temperature-controlled rolling line for medium and large-sized rolled pieces, including an upstream rolling mill 1, an intermediate water cooling device 2, an intermediate conveying roller table 3, a shearing machine 8, a downstream rolling mill 6, and an intermediate conveying roller A temperature control stand 4, 5 is respectively arranged on both sides of the road 3, and a rolled piece conveying mechanism is also arranged between the temperature control stand 4, 5 and the intermediate conveying roller table 3, between the upstream rolling mill 1 and the intermediate water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com