Closed well washing device

A technology of well flushing and well flushing valve, applied in the direction of flushing wellbore, sealing/isolation, wellbore/well components, etc., can solve the problem of direct contact between well flushing water and oil layer, etc., to avoid contact and reduce water consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

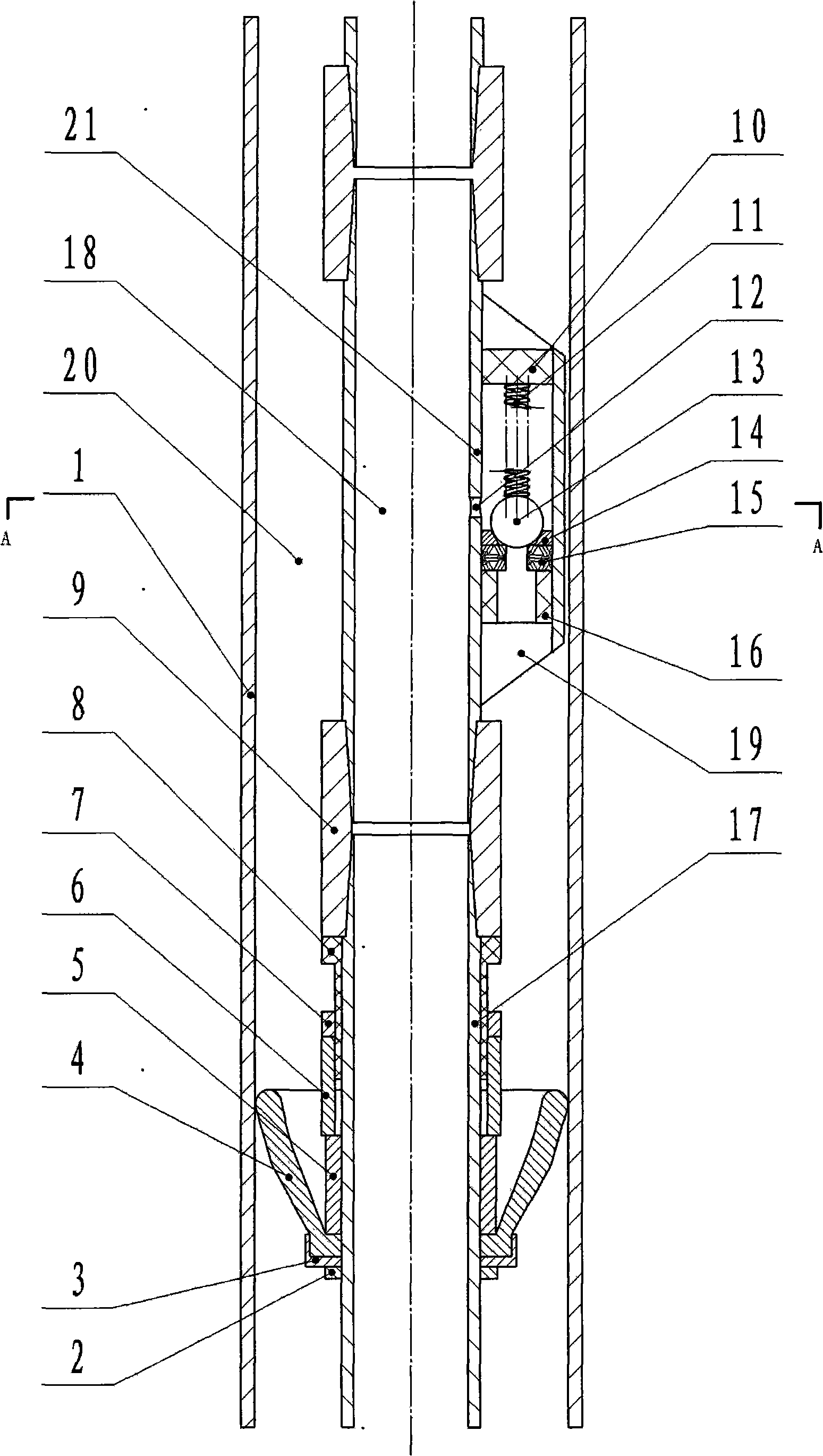

[0017] This implementation includes eccentric flush valves and cup packers.

[0018] In this embodiment, the oil well is connected in series with the oil pipe below the waxing point of the oil well.

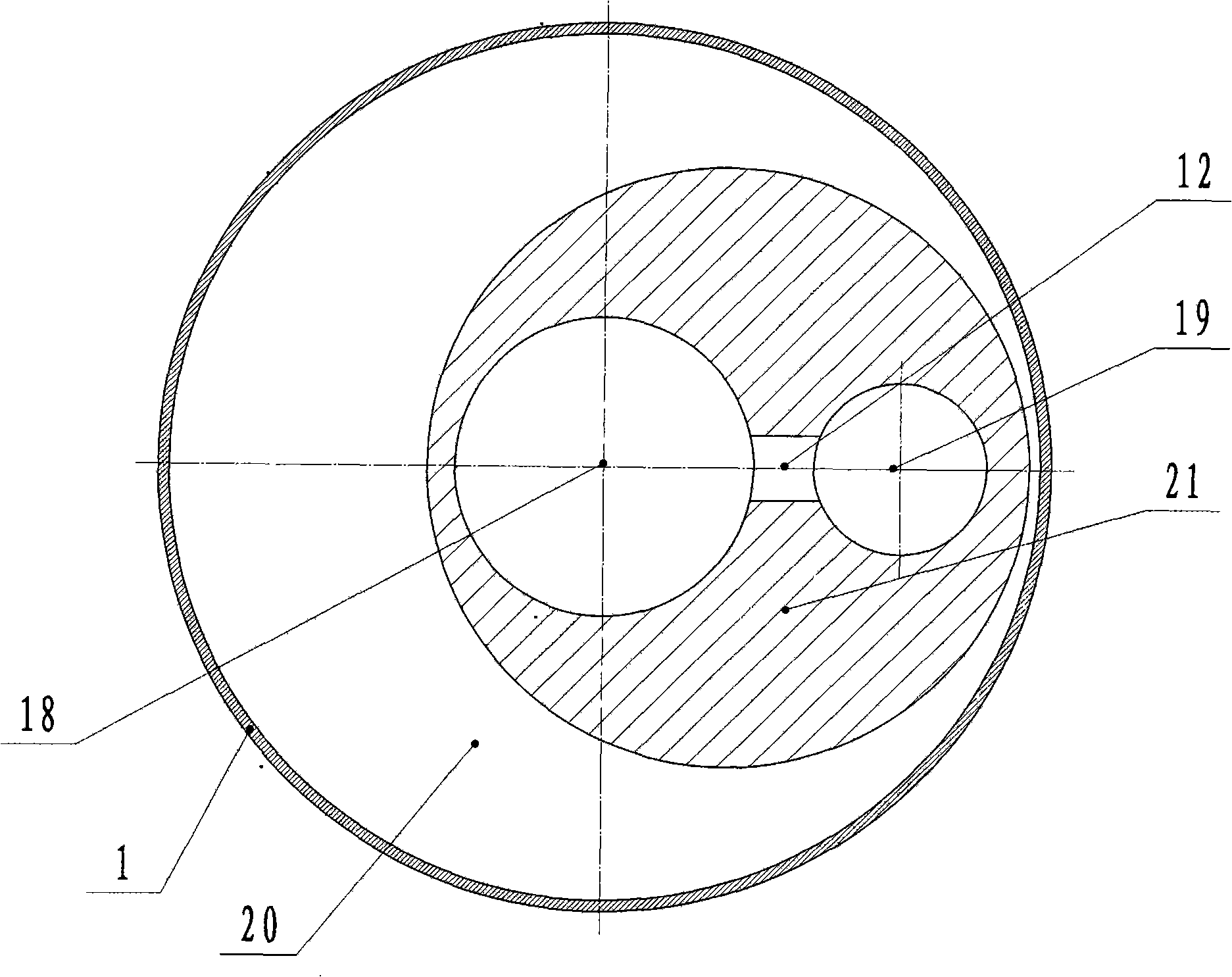

[0019] The oil passage hole of the eccentric well flushing valve is installed concentrically with the oil pipe, and the pressure control hole is set on one side of the oil passage hole. A flow hole is provided between the pressure control hole and the oil hole for communication. The upper part of the pressure control hole is provided with a female plug, which is connected with the pressure control hole with a screw. A spring is arranged under the female plug, and a sealing ball is connected to the lower end of the spring. The lower part of the pressure control hole is provided with a sealing ball seat pressure cap, which is connected with the pressure control hole with a screw. A sealed ball seat is arranged on the pressure cap of the sealed ball seat. The sealing ball seat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com