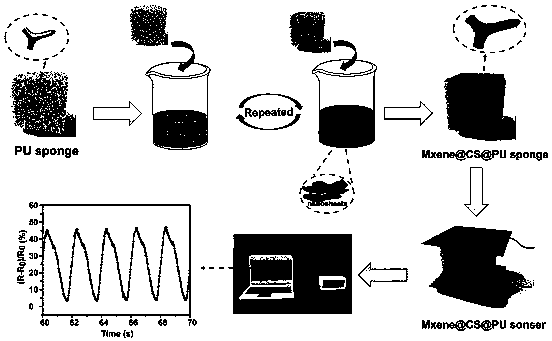

Mxene@chitosan@polyurethane foam three-dimensional composite material, and preparation method and application thereof

A technology of polyurethane foam and composite materials, which is applied in the measurement of the property force of piezoelectric resistance materials and the measurement of fluid pressure by changing the ohmic resistance. It can solve the problems of cumbersome preparation methods, high cost and limitations, and avoid operation The effect of simple process and preparation method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

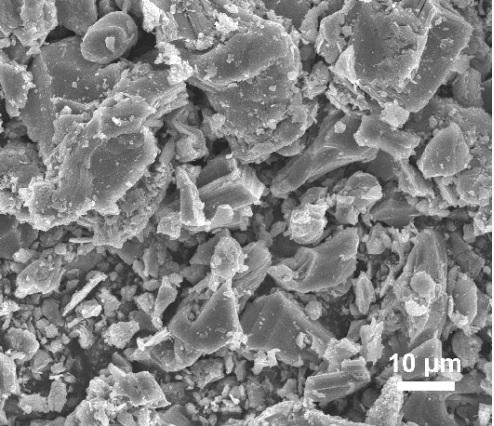

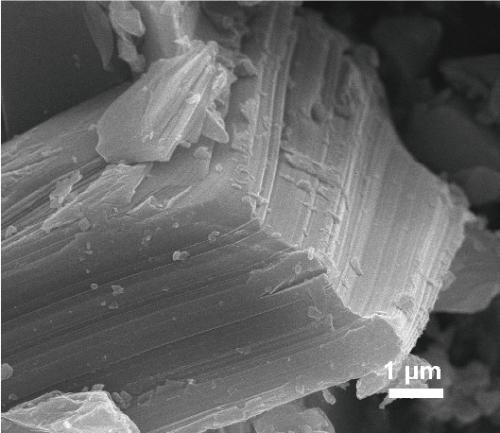

[0053] The preparation method of Mxene nano sheet is as follows:

[0054] (1) The MAX precursor is sieved with 500 mesh;

[0055] (2) Add 10ml of deionized water into the polytetrafluoroethylene container, and put it in an ice bath, so that the temperature of the deionized water drops below 5°C, slowly add 20ml of HCl under the condition of magnetic stirring, and continue to stir until the temperature drops to 5°C Next, add 1g LiF and stir for 1h;

[0056] (3) Divide the screened MAX precursor into 5 times and add slowly at an interval of 12 minutes each time. After the addition, naturally raise the temperature to room temperature for 30 minutes, and then raise the temperature to 35°C for 25-28 hours;

[0057] (4) Centrifuge the reacted product at 3500rpm for 5min, repeat N times until the pH of the supernatant reaches about 7;

[0058] (5) Collect the final neutral or near-neutral suspension, and ultrasonically strip it for 0-1h under the protection of argon;

[0059] (6) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com