Method for surface nanocrystallization modification of metal material and preparation of nanometer-micrometer gradient structure

A metal material and gradient structure technology, applied in the field of material surface treatment, can solve the problems of long treatment time and high treatment temperature, and achieve the effect of improving surface nanometerization quality, high treatment efficiency, and optimizing surface structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

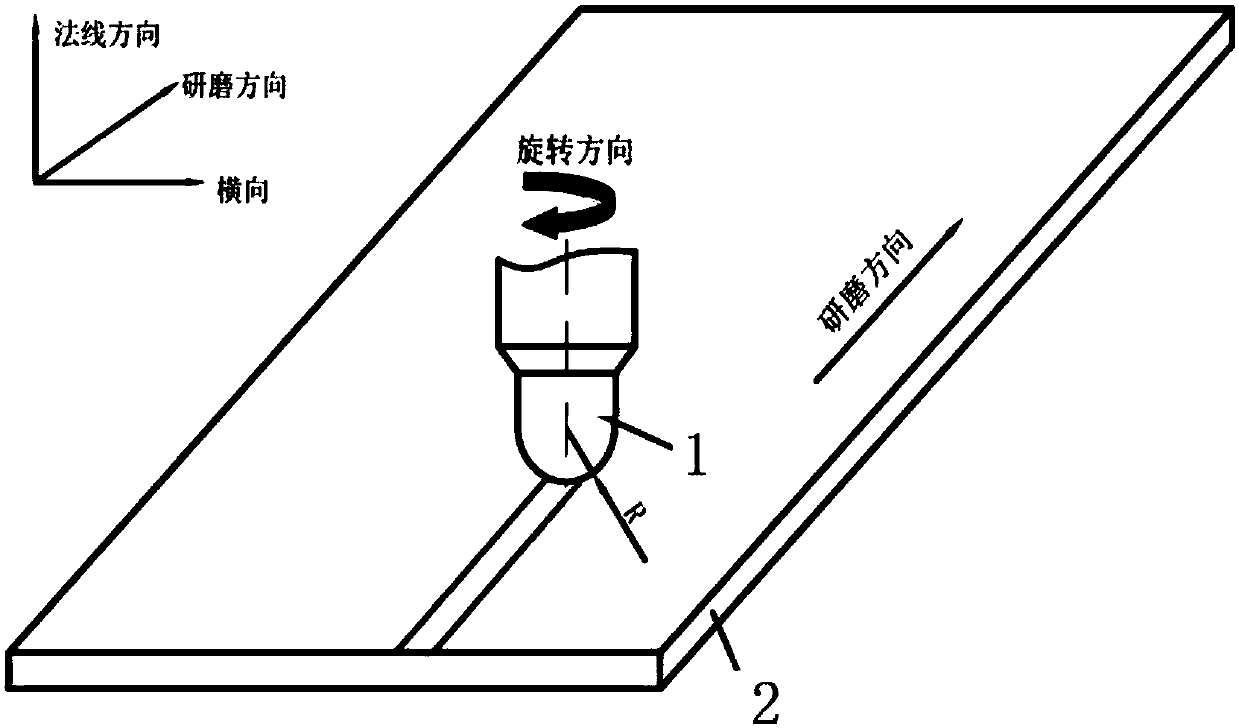

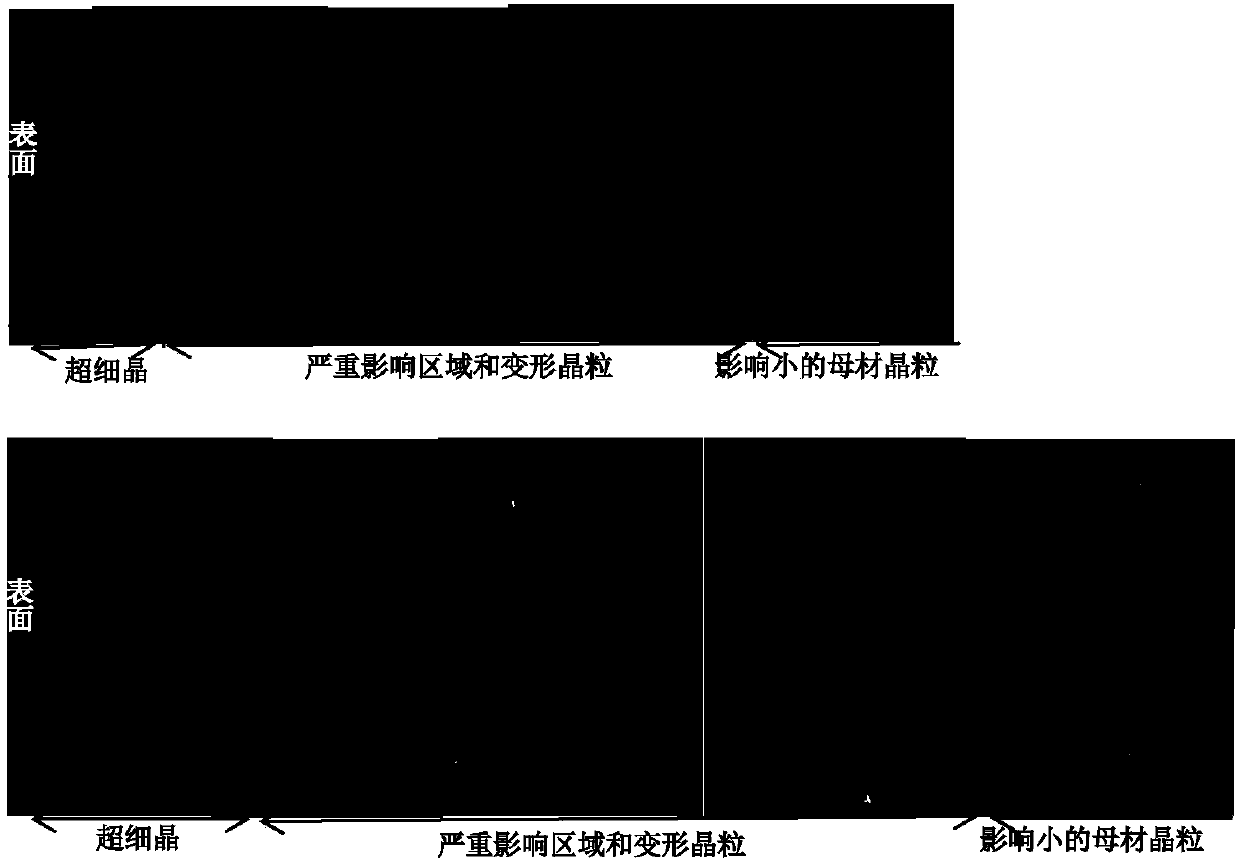

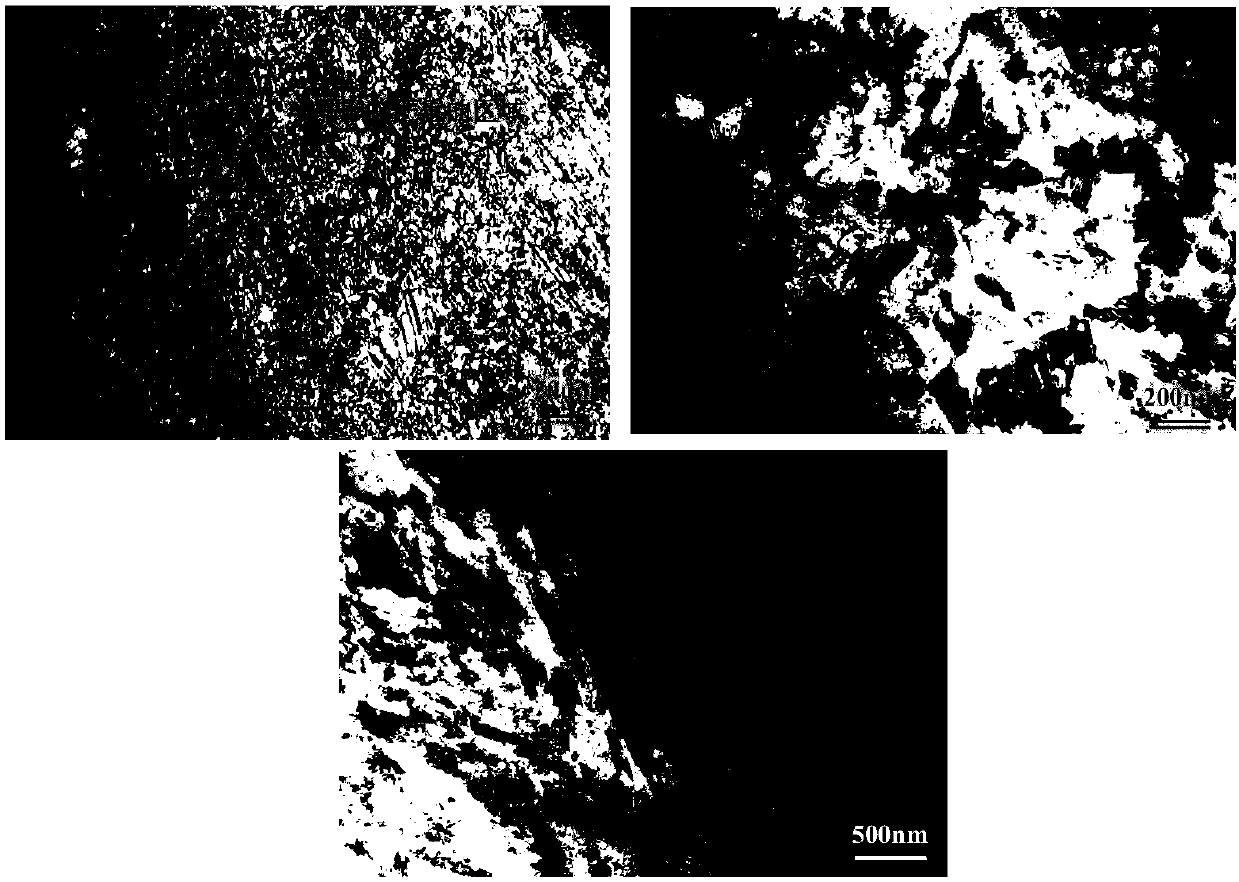

[0034] The present invention is based on the transformation of the tool head of the ordinary friction stir welding device, and develops a novel Surface Mechanical Rolling Grinding Treatment (SMRGT) method, which is a method for nano-modification of the surface of metal materials: The surface layer is subjected to multi-layer mechanical rolling grinding to prepare surface nanocrystals, so as to realize the surface self-nanoization of the metal material surface modification, wherein each layer of mechanical rolling grinding is based on the area of the tool head and the surface area of the metal material that needs surface treatment, through the tool The multi-pass mechanical rolling grinding of the head is completed step by step.

[0035] The design of the tool head and the nano-modification process of the Mg alloy surface are as follows ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com