Method for treating pile-forming mud-clamping defect of large-diameter filling pile of bridge

A treatment method and large-diameter technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve problems such as high cost, clean up, unusable piles, etc., to reduce time and cost, improve treatment effect, and operation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

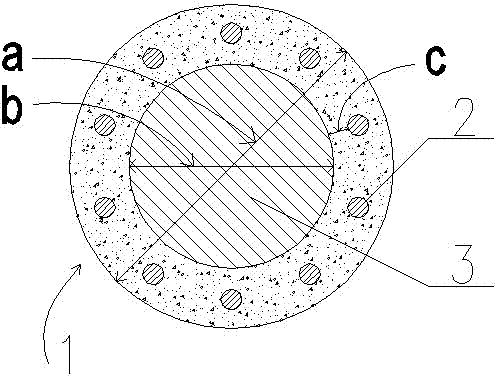

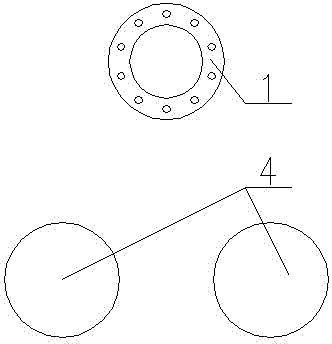

[0019] Such as figure 1 As shown, the present invention comprises the following steps: first, according to the ultrasonic detection or small strain detection report, determine the depth of the mud inclusion defect part, and compare the geological data of the design drawing to grasp the geological characteristics around the defect part; then according to the pile foundation 1 The size of the pile diameter a is centered on the center point of the steel cage 2 plane, and the diameter b of the core area 3 that needs to be chiseled out is determined. At the same time, it should be ensured that the thickness c of the inner protective layer of the steel cage 2 is greater than the diameter b of the core area 3 equal to 10 centimeters, wherein the pile diameter a of pile foundation 1 is greater than or equal to 130 centimeters (in this implementation case, the pile diameter a of pile foundation 1 is 150 centimeters); Well, the depth of the dewatering well 4 should be more than 1 meter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com